Environment-friendly low-temperature efficient metal cleaner

A metal cleaning agent, an environmentally friendly technology, applied in the field of metal cleaning agents, which can solve the problems of low cleaning power, non-compliance with safety and environmental protection, and poor low-temperature decontamination ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

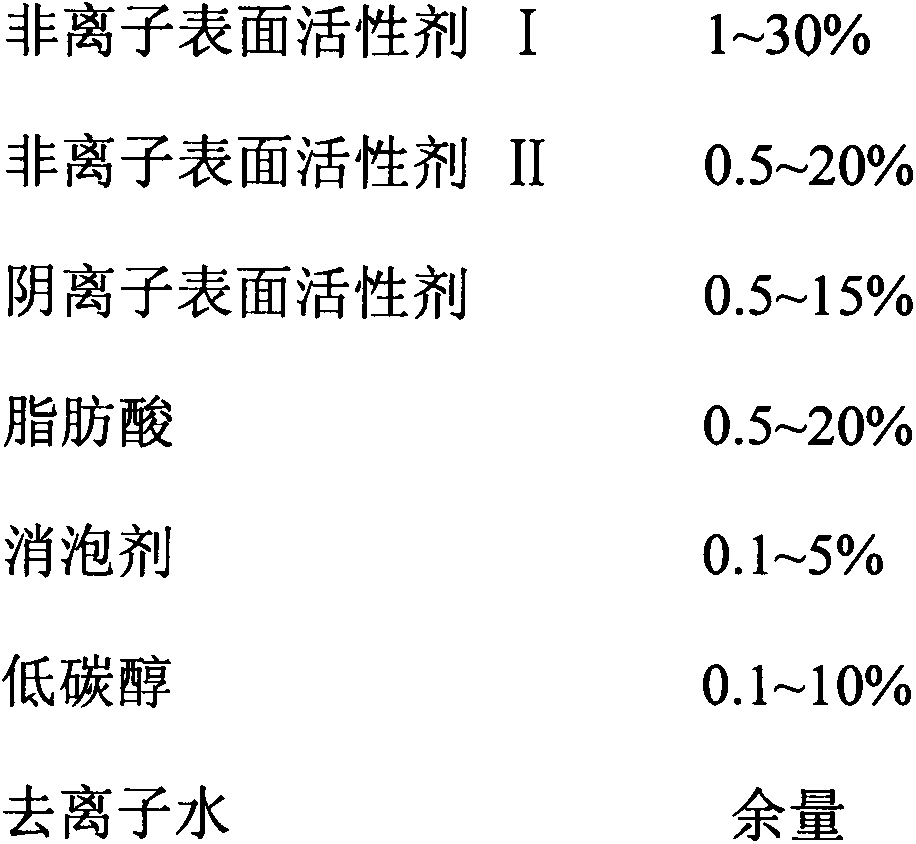

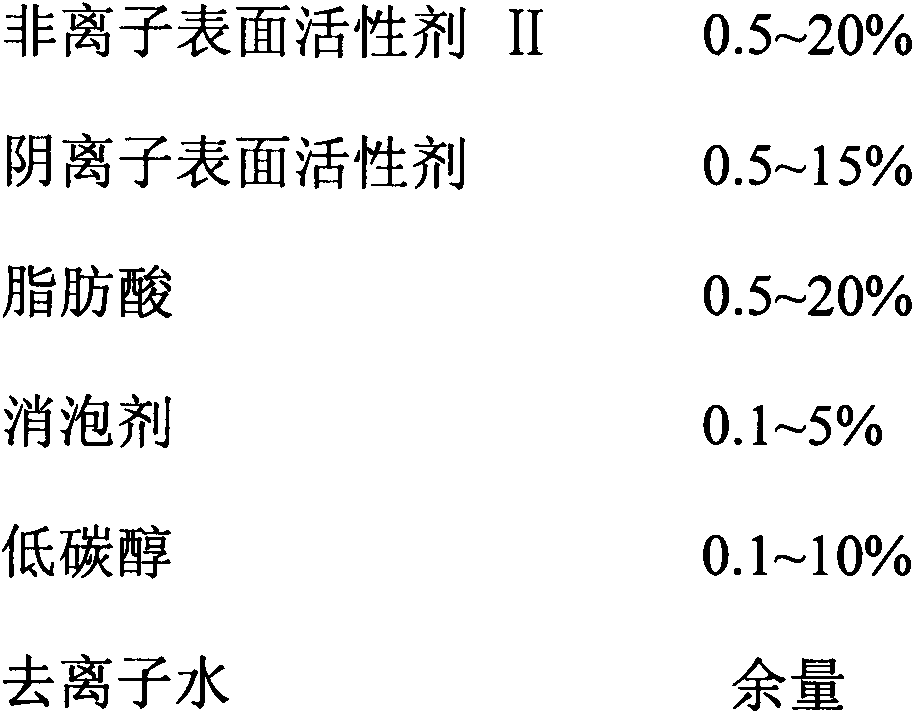

Method used

Image

Examples

Embodiment 1

[0012] a. At 50°C, add 6Kg of dodecylamine polyoxyethylene 5 ether and 4Kg of stearylamine polyoxyethylene 8 ether into the container, then slowly add 2Kg of lauric acid and stir at a speed of 350r / min 1h;

[0013] b. Add 10KgJFC-2 and 8Kg sodium lauryl sulfate to a, and stir for 10min;

[0014] c. Add 0.4Kg hydroxy silicone oil to b, and stir for 10 minutes;

[0015] d. Add 3Kg of isopropanol and 76.6Kg of deionized water to c, and stir for 1 hour to obtain a cleaning agent product.

Embodiment 2

[0017] a. At 50°C, add 5Kg of dodecylamine polyoxyethylene 15 ether, 6Kg of octadecylamine polyoxyethylene 5 ether, and 4Kg of octadecylamine polyoxypropylene 10 ether into the container, and then slowly Add 3Kg of lauric acid and stir for 1h at a speed of 350r / min.

[0018] b. Add 8KgJFC-2 and 8Kg sodium lauryl sulfate to a, and stir for 10min;

[0019] c. Add 0.6Kg hydroxy silicone oil to b, and stir for 10 minutes;

[0020] d. Add 4Kg of isopropanol and 61.4Kg of deionized water to c, and stir for 1 hour to obtain a cleaning agent product.

Embodiment 3

[0022] a. At 50°C, add 7Kg of dodecylamine polyoxyethylene 10 ether and 6Kg of dodecylamine polyoxyethylene 5 ether into the container, then slowly add 3.5Kg of lauric acid at a speed of 350r / min Stir for 1h.

[0023] b. Add 5KgJFC-2, 4KgJFC-6 and 11Kg sodium lauryl sulfate to a, and stir for 10min;

[0024] c. Add 0.5Kg hydroxy silicone oil to b, and stir for 10 minutes;

[0025] d. Add 3Kg of isopropanol and 60Kg of deionized water to c, and stir for 1 hour to obtain a cleaning agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com