Two-sectional inclined folding blade device for large wind-driven generator

A technology for wind turbines and folding blades, which is applied to wind turbine components, wind turbine control, wind turbines, etc., can solve the problems of difficult transportation and installation, difficult inertial control, complicated control procedures, etc., and achieves startup and shutdown. Simple control, easy to manufacture and assemble, high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, structure of the present invention and specific embodiment are described further:

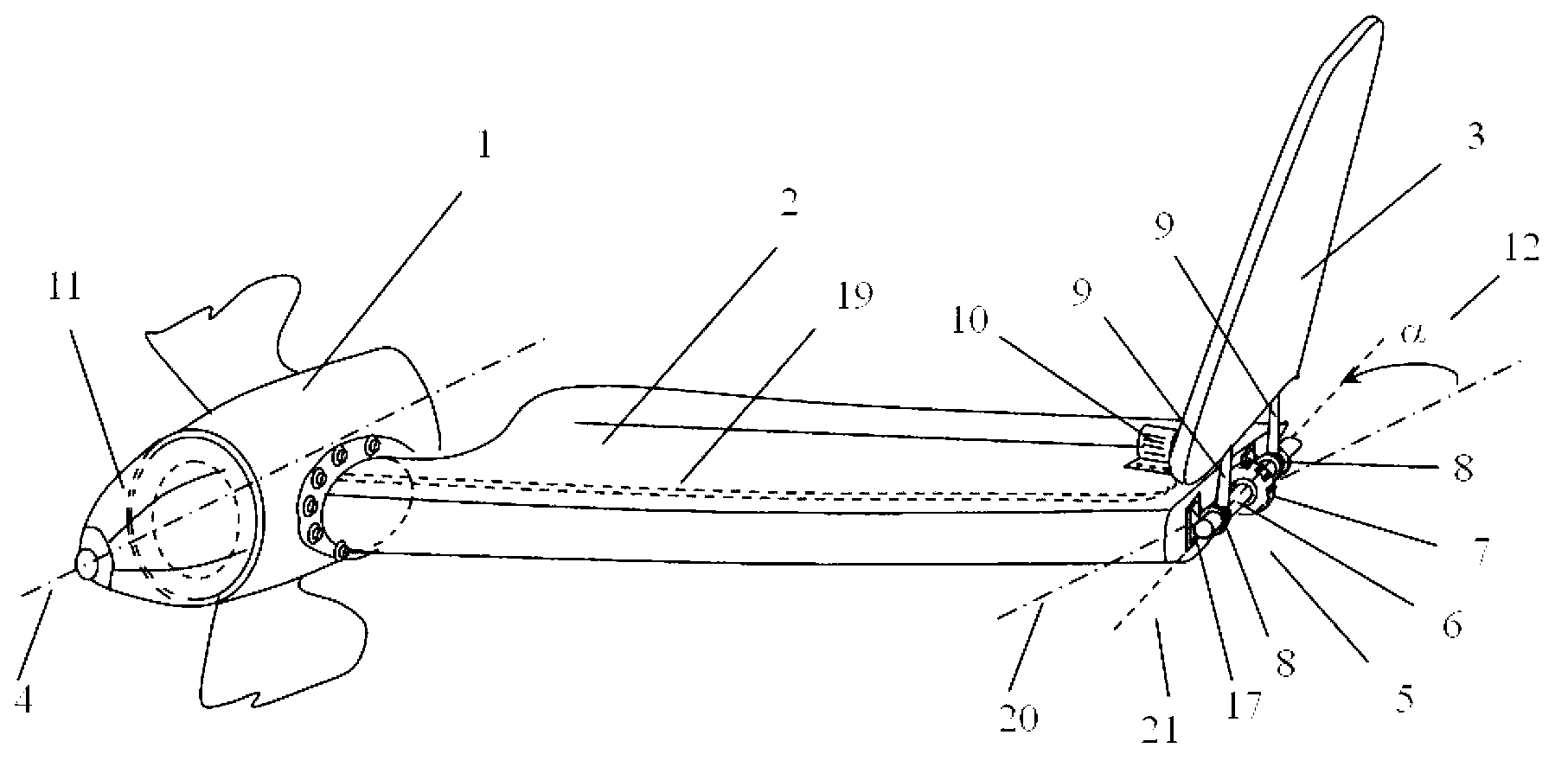

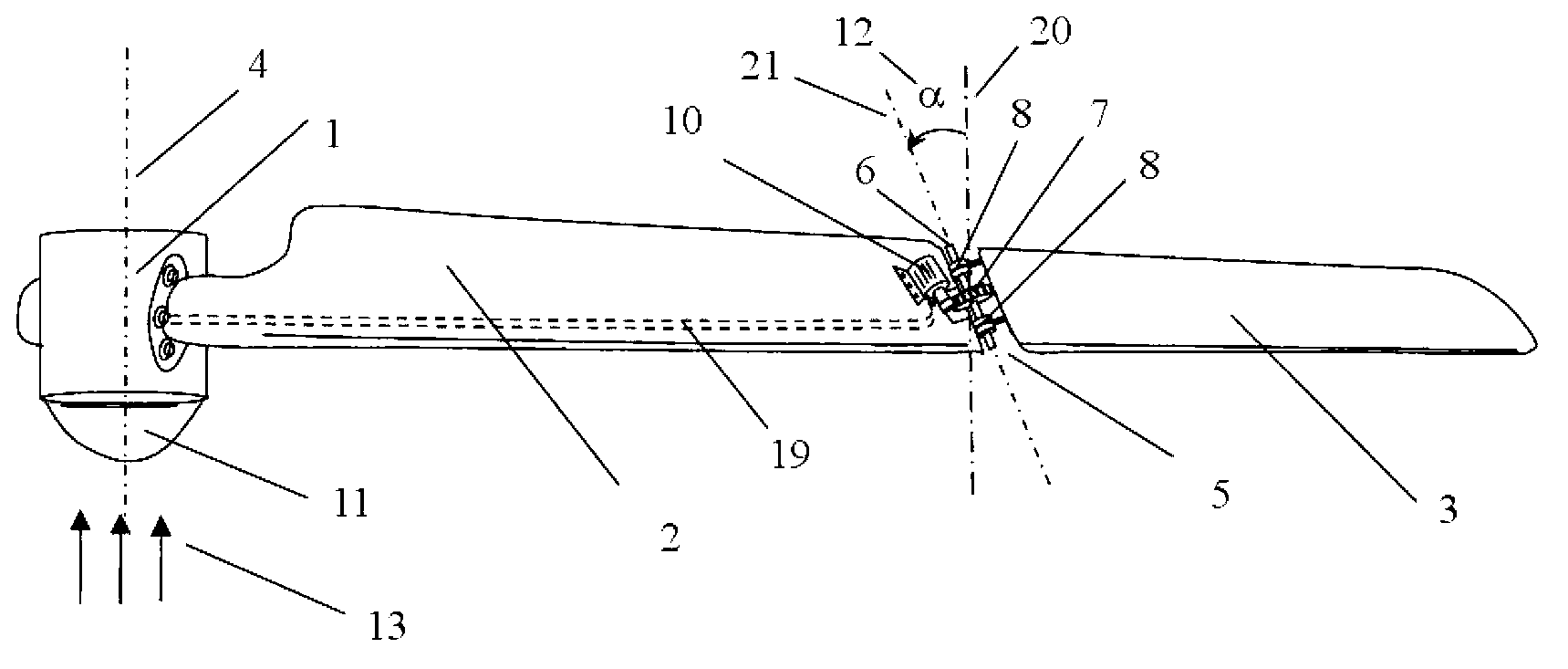

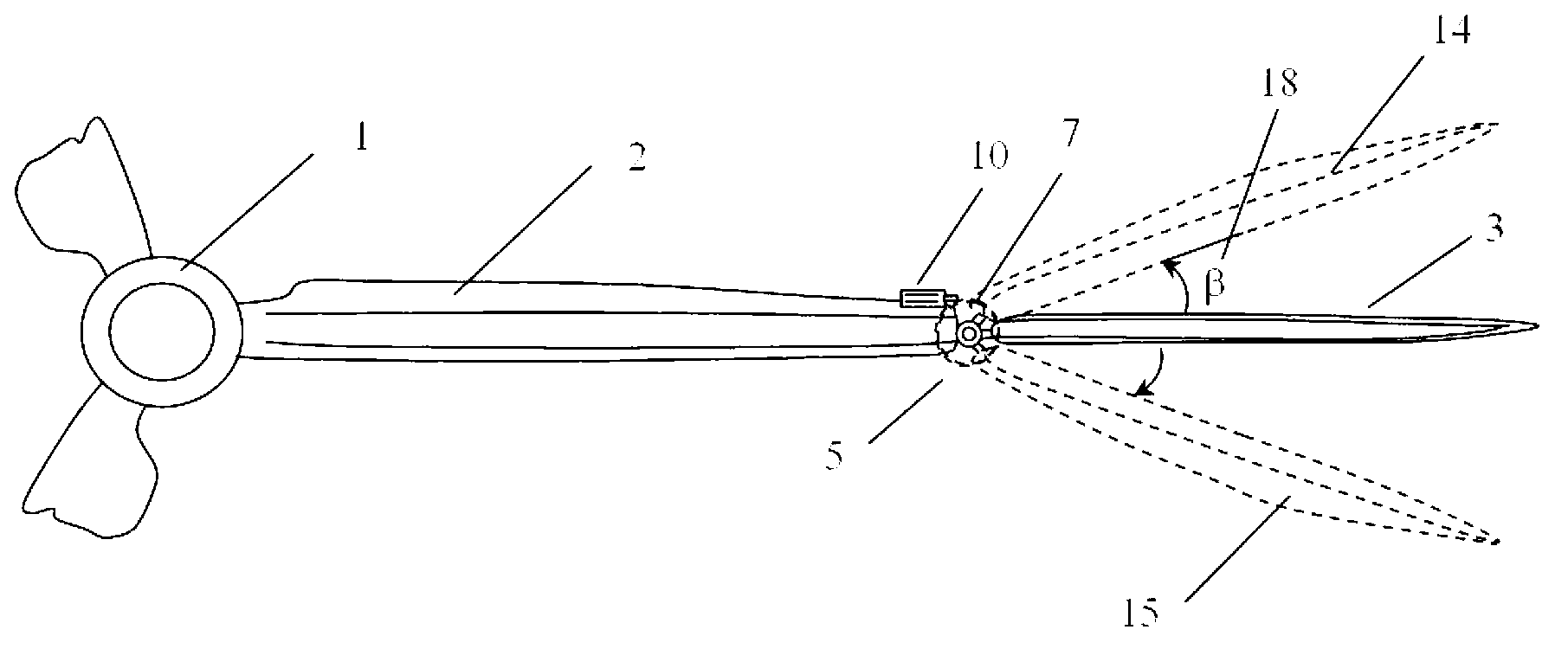

[0026] figure 1 Schematic diagram of a two-stage inclined folding blade device for a large-scale wind power generator provided by the present invention, the device contains a fan hub 1, a main blade 2, a folding blade 3 and a blade connecting device 5; each blade is composed of a main blade 2 and The folded blades 3 are combined, and the main blades 2 are fixed blades, which are fixedly connected to the fan hub 1. The folded blades 3 are connected to the main blades 2 through the connecting device 5, and the folded blades are rotating blades; the blade connecting device 5 is connected to the main shaft 6 , rotating gear 7, rotating bearing 8, folding blade connecting bracket 9, connecting base 17 and folding blade driving motor 10, rotating gear 7 is fixed on the middle position of connecting main shaft 6, and there are two folding blade co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com