Airtight automatic de-rusting machine for pipeline repaired port

A rust remover and automatic technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of dust on workers' respiratory tract, increased labor intensity of workers, uncontrollable process quality, etc., to shorten the engineering cycle and save money. Sand, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

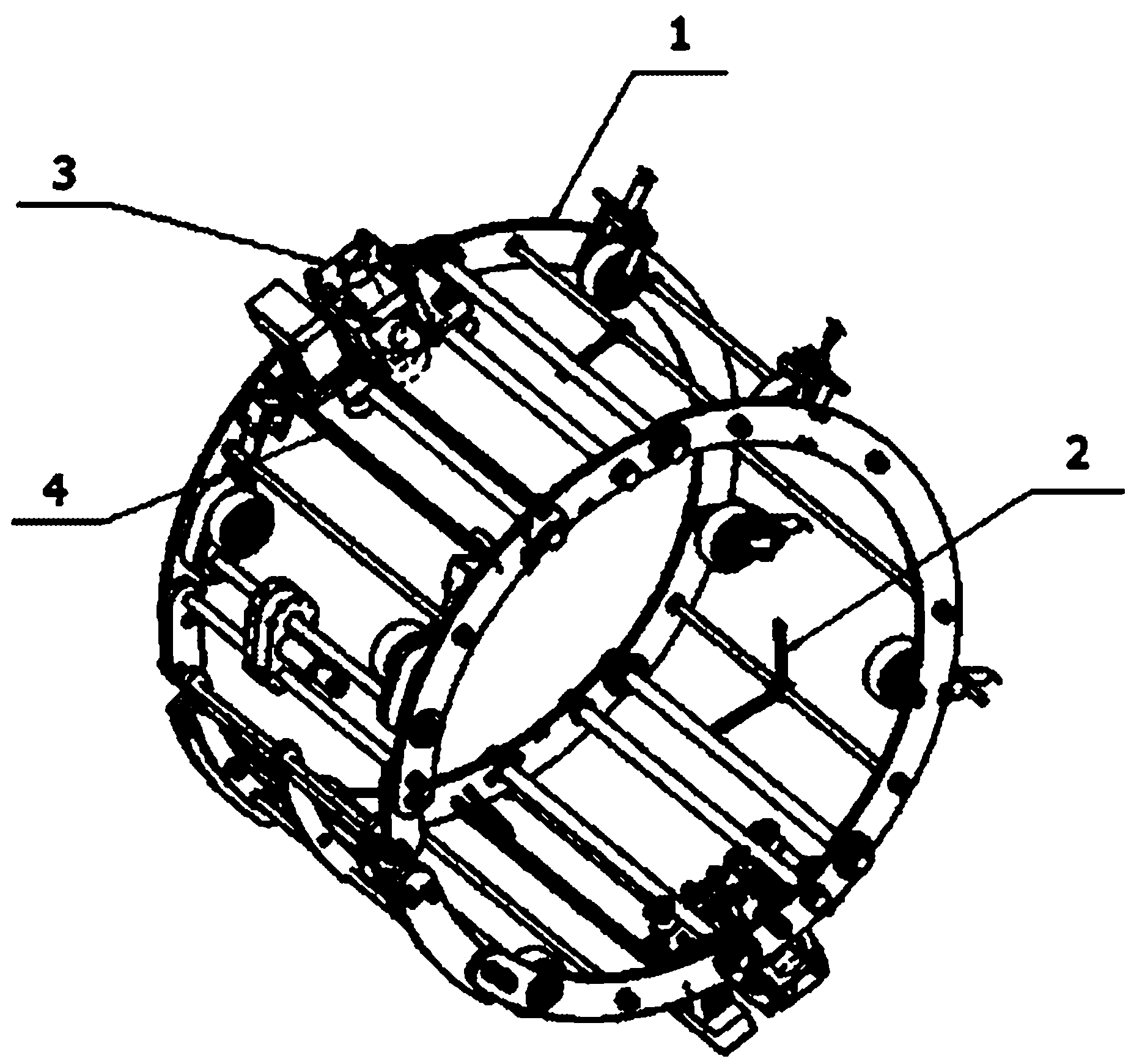

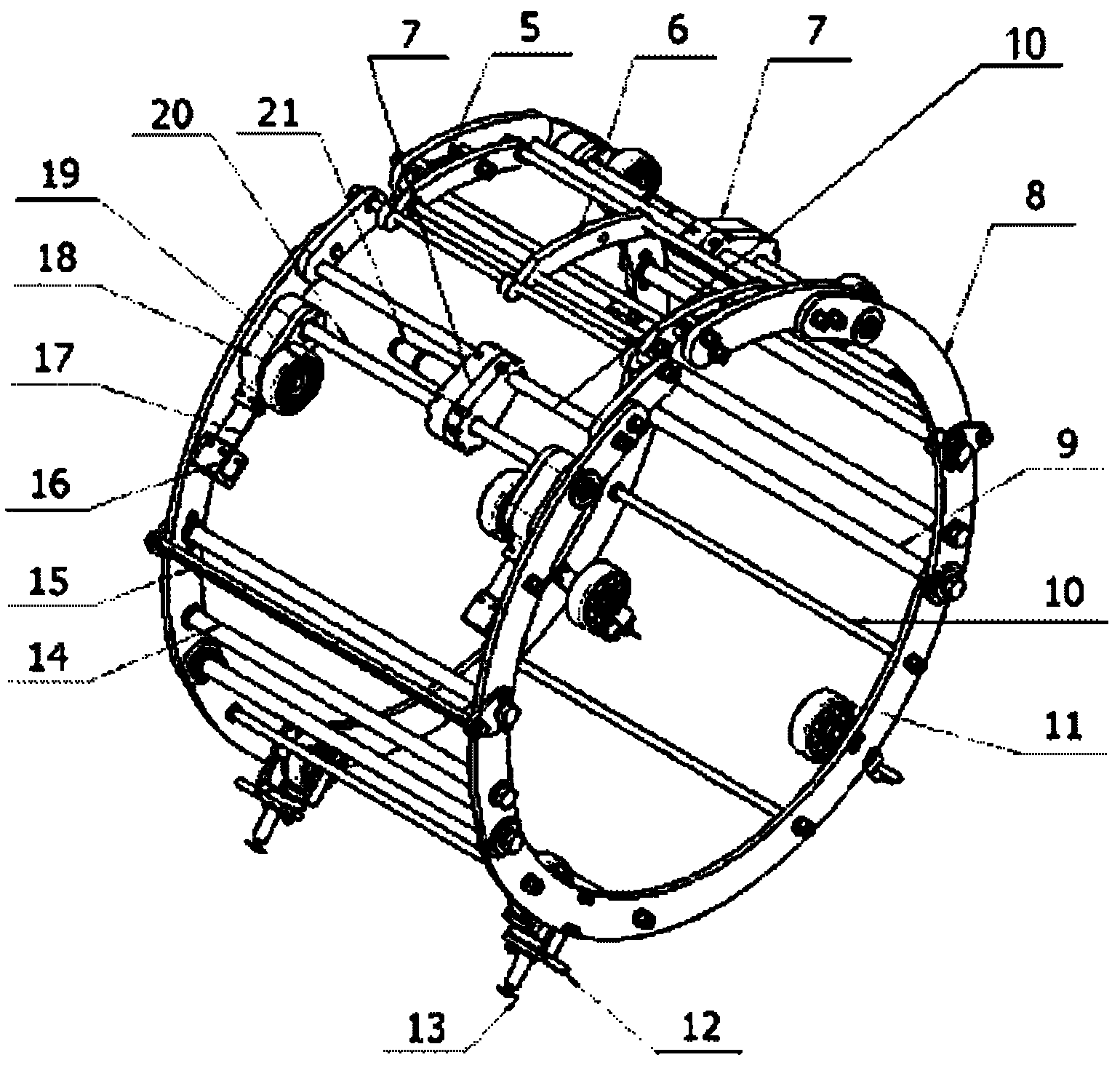

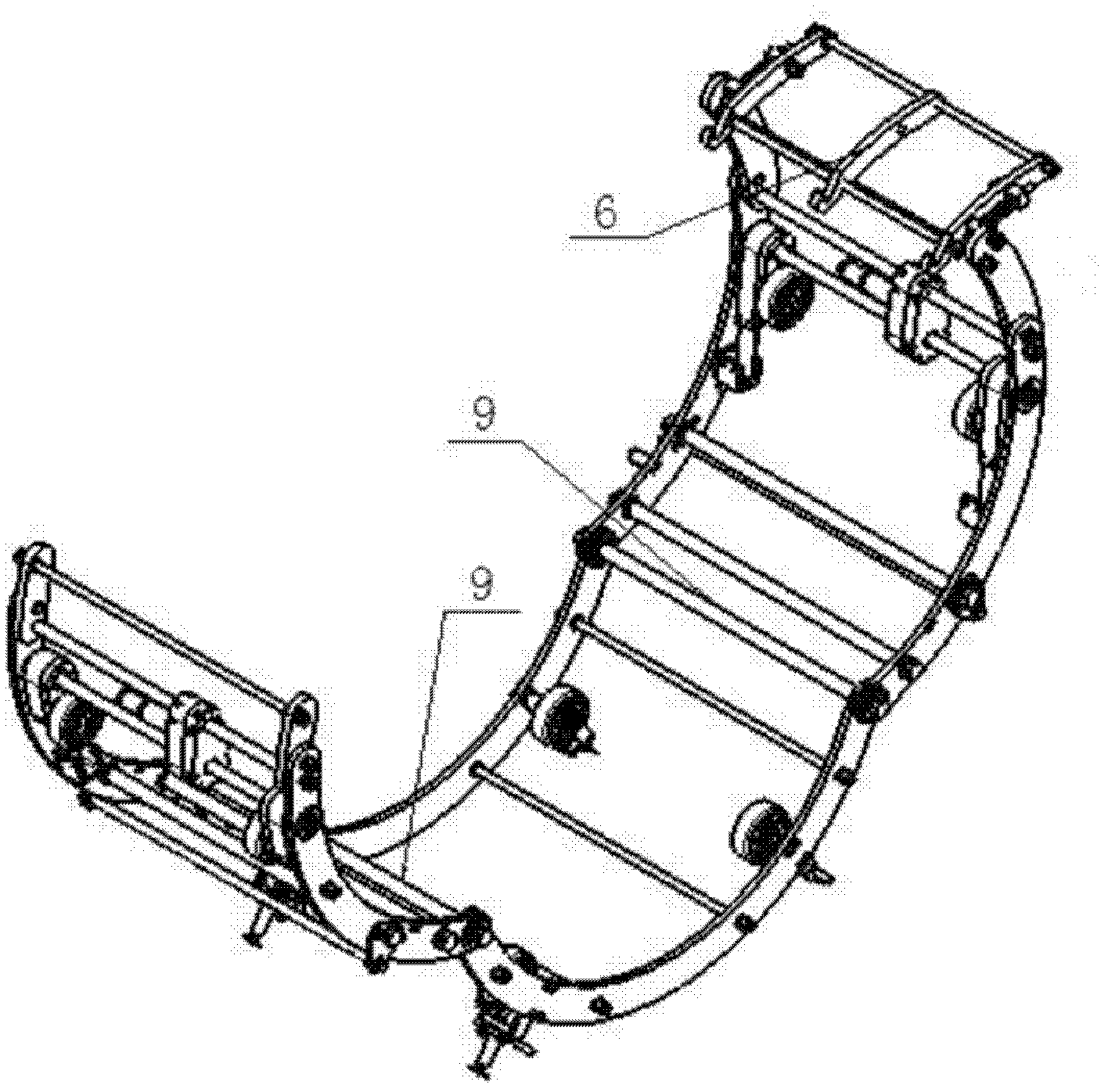

[0023] The four-drive walking device 1 of the present invention is a three-petal overlapping ring-shaped opening and closing structure, which is composed of two three-petal overlapping and opening-closing annular plate frames 8 connected by a rotating shaft 9, and the rotating shaft 9 is connected to the annular plate by bolts. Frame 8, and a copper pad is provided at the joint to prevent wear and tear when the ring structure is opened and closed. The hook-type quick clamping joint 6 with locking spring 5 is installed at the opening and closing opening of the ring plate frame 8, and is used to quickly place the four-drive traveling device 1 on the pipe section to be repaired. Between the annular plate frames 8, a cylindrical guide rod 14 and a rack 15 supporting the positioning and power transmission of the transverse traveling device 3 are installed, and a support rod 10 threaded for stabilizing the ring structure is also installed. The reduction gear group 7 connecting the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com