Resonance-type magnetoelectric sensor for ferromagnetic material defect detection and detection method thereof

A magnetoelectric sensor and defect detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of small magnetic field range, large volume, unsuitable for leakage magnetic field detection, etc., to achieve a wide magnetic field detection range and improve the effect of magnetic sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

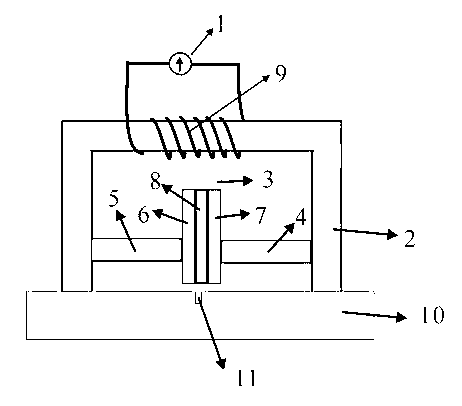

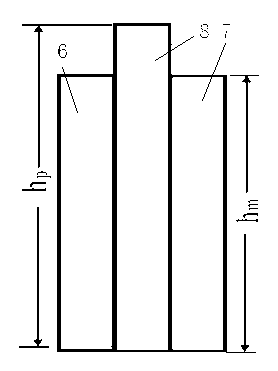

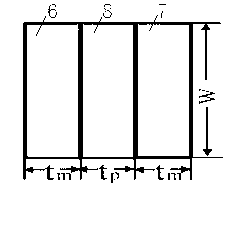

[0026] Such as Figure 1-5 As shown, a magnetoelectric element with a length of 12.5 mm, a width of 16 mm, and a thickness of 3 mm was fabricated. The length hm=12mm, width w=6mm, thickness tm=2mm of each magnetostrictive material block 6 and 7 of Terfenol-D material used in the magnetoelectric element; the length hp= of the piezoelectric material block 8 of PZT5A material used 12.5mm, its width and thickness are the same as those of magnetostrictive materials 6,7. A permanent magnet 3 of NdFeB material with a diameter of R=6mm and a height of wm=4mm is placed at one end of the magnetoelectric element to realize the bias magnetization of the magnetostrictive material blocks 6,7, and the bias magnetic field is along the length of the magnetoelectric element direction. The magnetoelectric element is the polarized Pb(Zr 1-x Ti x )O 3 (PZT5A) material and Terfenol-D (TbDyFe) material are pasted with epoxy resin. The supporting beams 4 and 5 are made of organic glass material.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com