Auxiliary heating system for liquid-metal-cooled natural circulation reactor

A liquid metal cooling and natural circulation technology, applied in reactors, cooling devices, reducing greenhouse gases, etc., can solve problems such as inability to provide auxiliary heating, improve reliability and safety, improve reliability and safety, and increase temperature evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

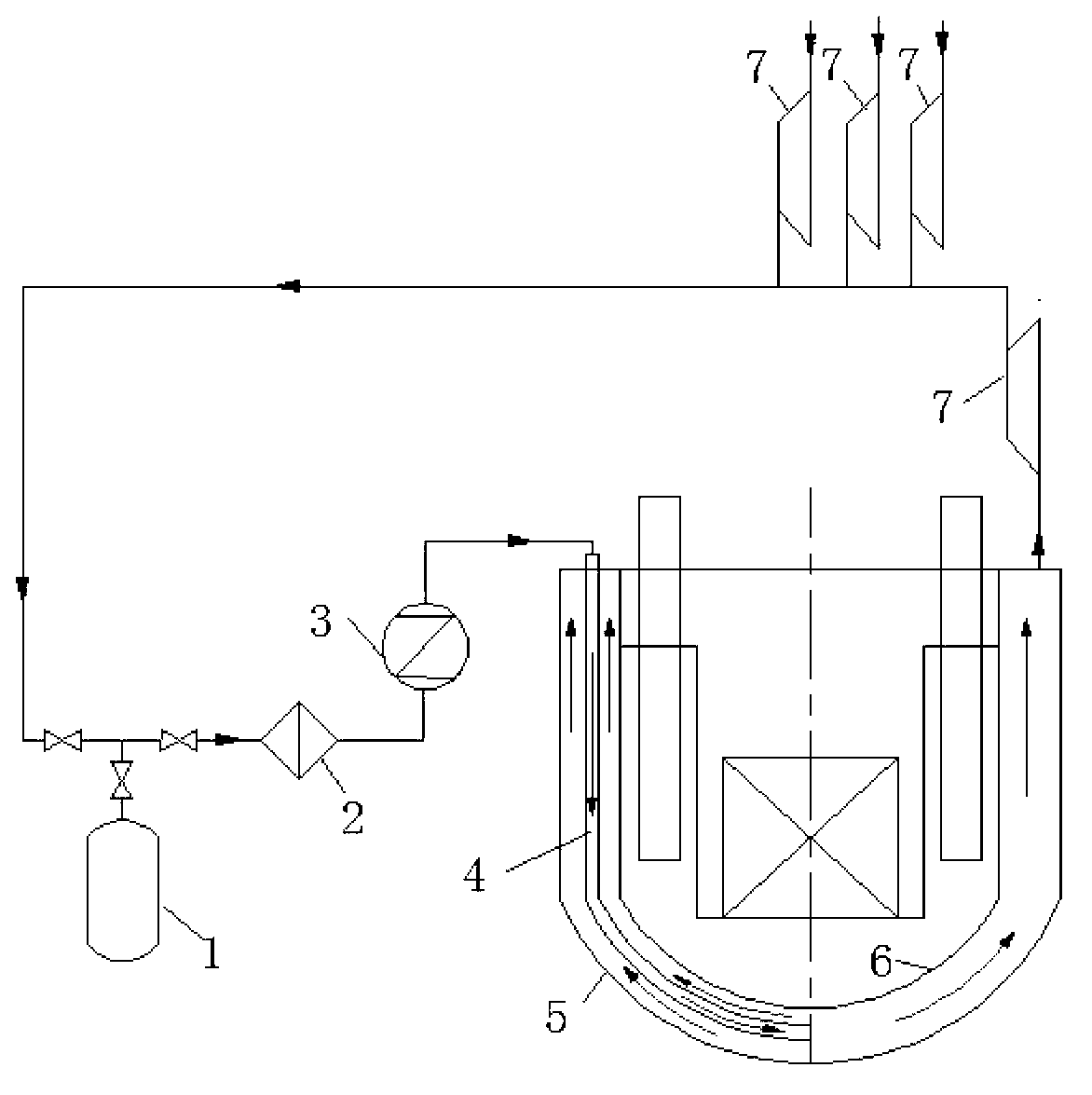

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

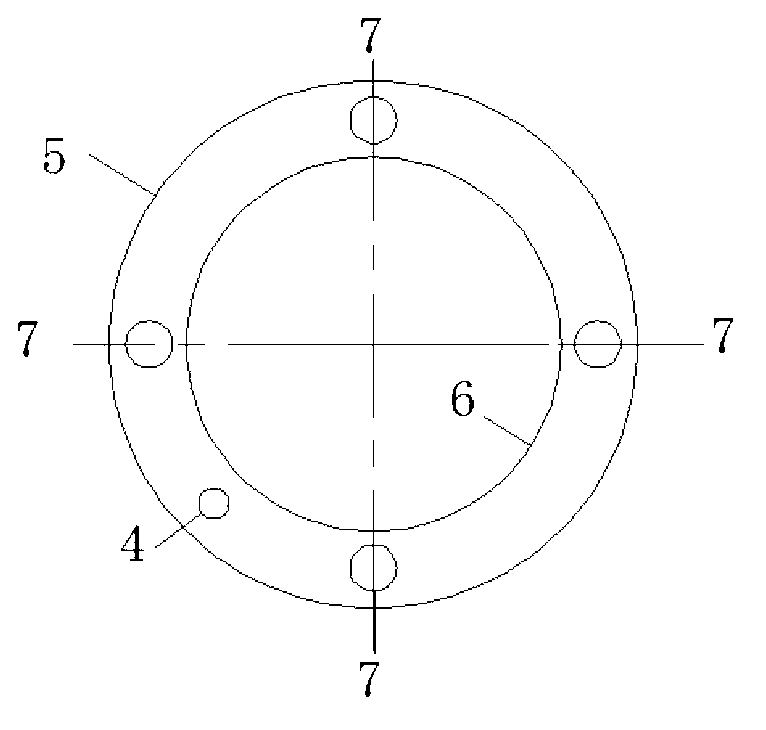

[0023] The system includes a nitrogen storage tank 1, a filter 2, a gas heater 3, a hot nitrogen input pipe 4, a safety container 5, a main container 6, an air extractor 7, and pipes and valves connected between devices. The nitrogen storage tank 1 is connected to the filter 2, then connected to the gas heater 3, and finally connected to the hot nitrogen input pipeline 4. The installation hole of a hot nitrogen inlet pipe 4 is arranged on the top cover of the stack, and the outlet of the pipe is located at the bottom of the annular cavity formed by the main container 6 and the safety container 5 . The installation holes of the four air extractors 7 are evenly arranged on the top cover of the pile, and the nitrogen gas that has undergone heat exchange in the ring cavity is extracted to complete the nitrogen closed cycle process.

[0024] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com