Galvanized beryllium bronze rod with ball head

A technology of beryllium bronze and ball head, applied in the field of beryllium bronze alloy materials, can solve the problems of weak electrical conductivity, inability to meet the upgrading of electrical products, and inapplicability, and achieve the effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

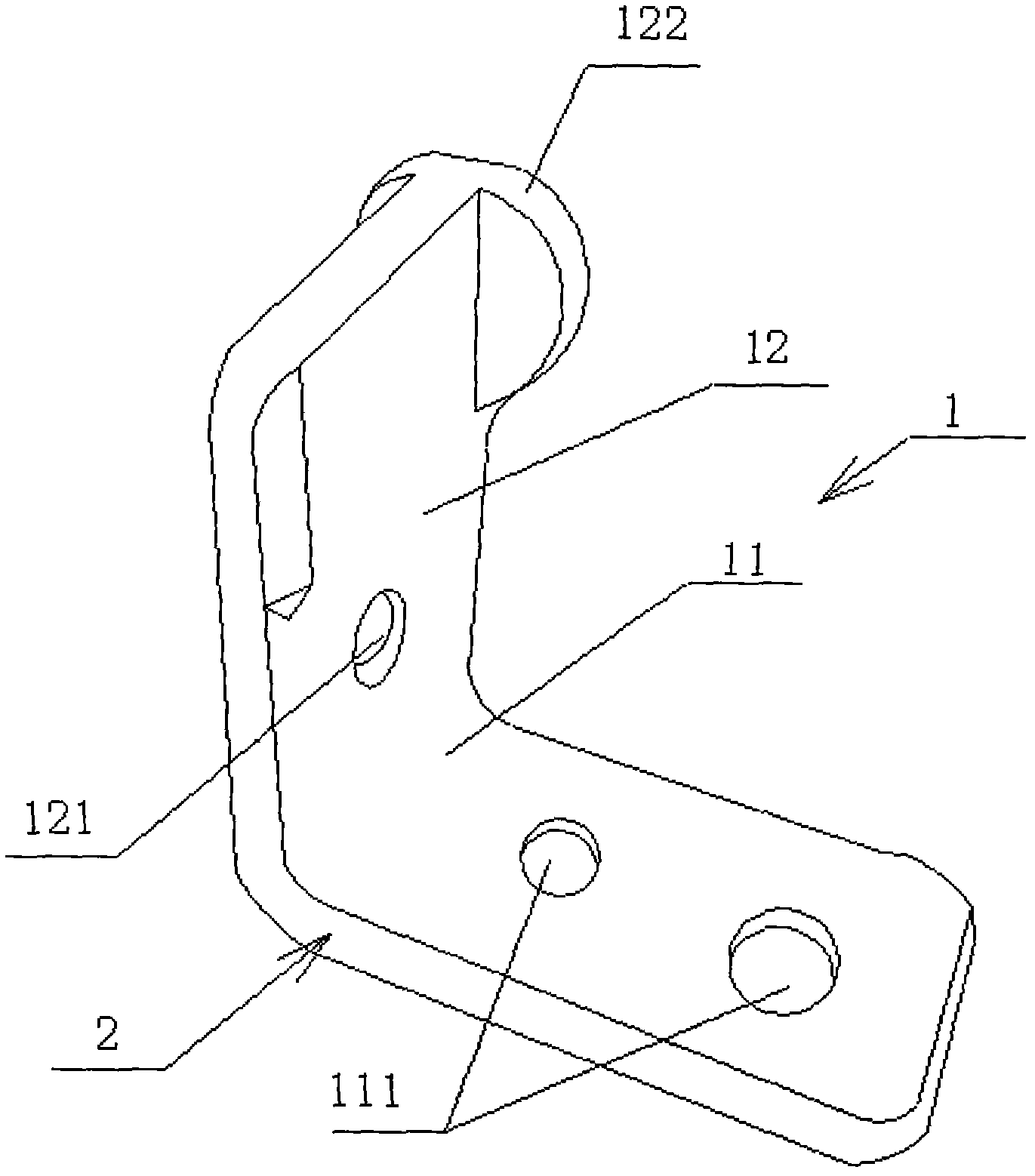

[0015] see figure 1 , figure 1 It is a schematic diagram of the three-dimensional structure of the L-shaped beryllium bronze rod for electrician of the present invention. Depend on figure 1 It can be seen that the galvanized beryllium bronze rod with a ball head of the present invention includes a beryllium bronze rod body 1, and the cross section of the beryllium bronze rod body 1 is an "L"-shaped structure, and the "L"-shaped structure consists of a transverse section 11 is composed of a vertical section 12, a first through hole 111 is opened in the middle of the horizontal section 11, a second through hole 121 is opened in the middle of the vertical section 12, and a Ball head 122, and a layer of metal zinc 2 is plated on the outer surface of the beryllium bronze rod body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com