Novel 4*4 Butler matrix feed network

A feeding network and matrix technology, applied in the field of 4×4 Butler matrix feeding network, to achieve the effect of reducing volume, improving electrical performance, and increasing applicable occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

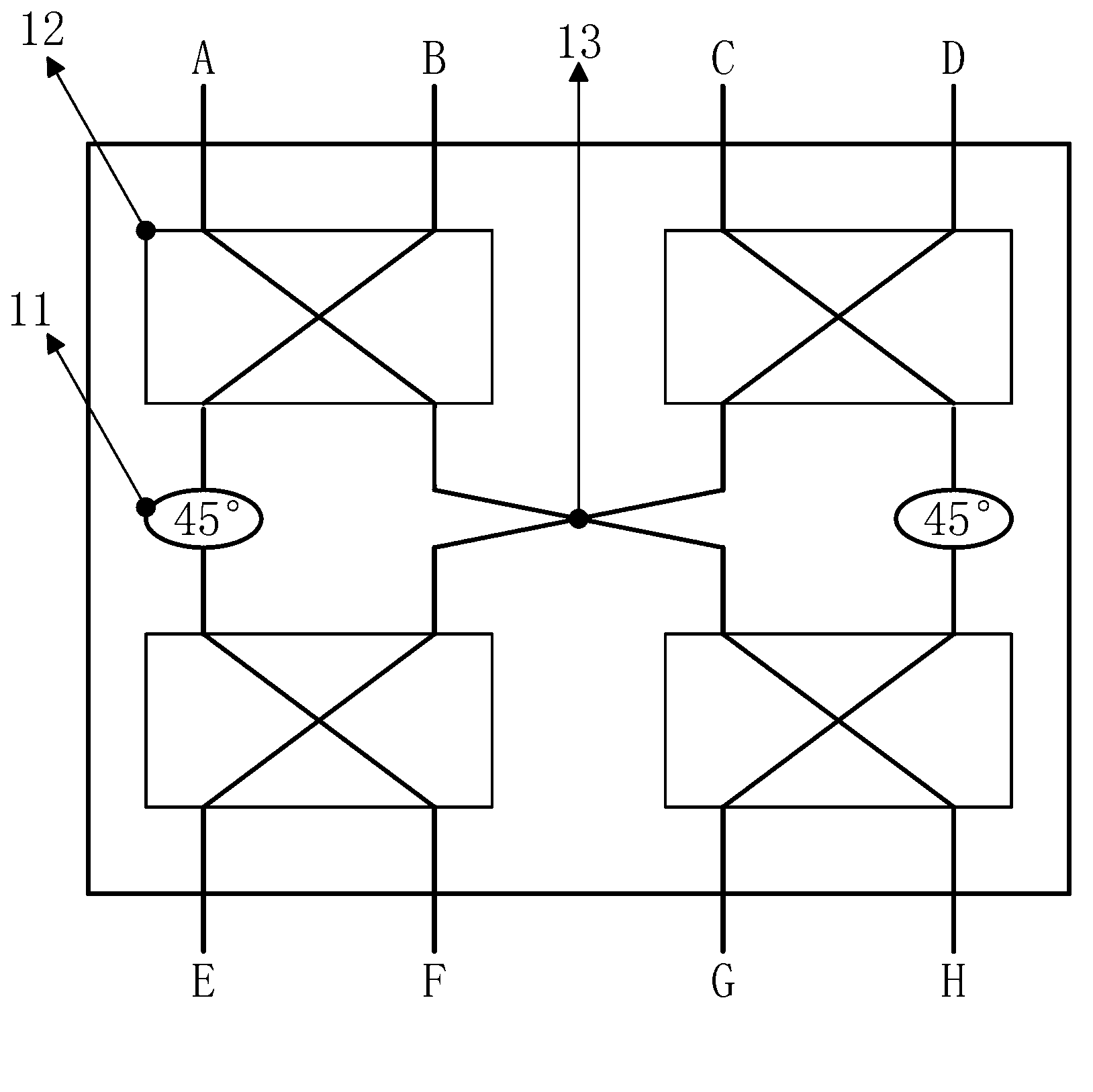

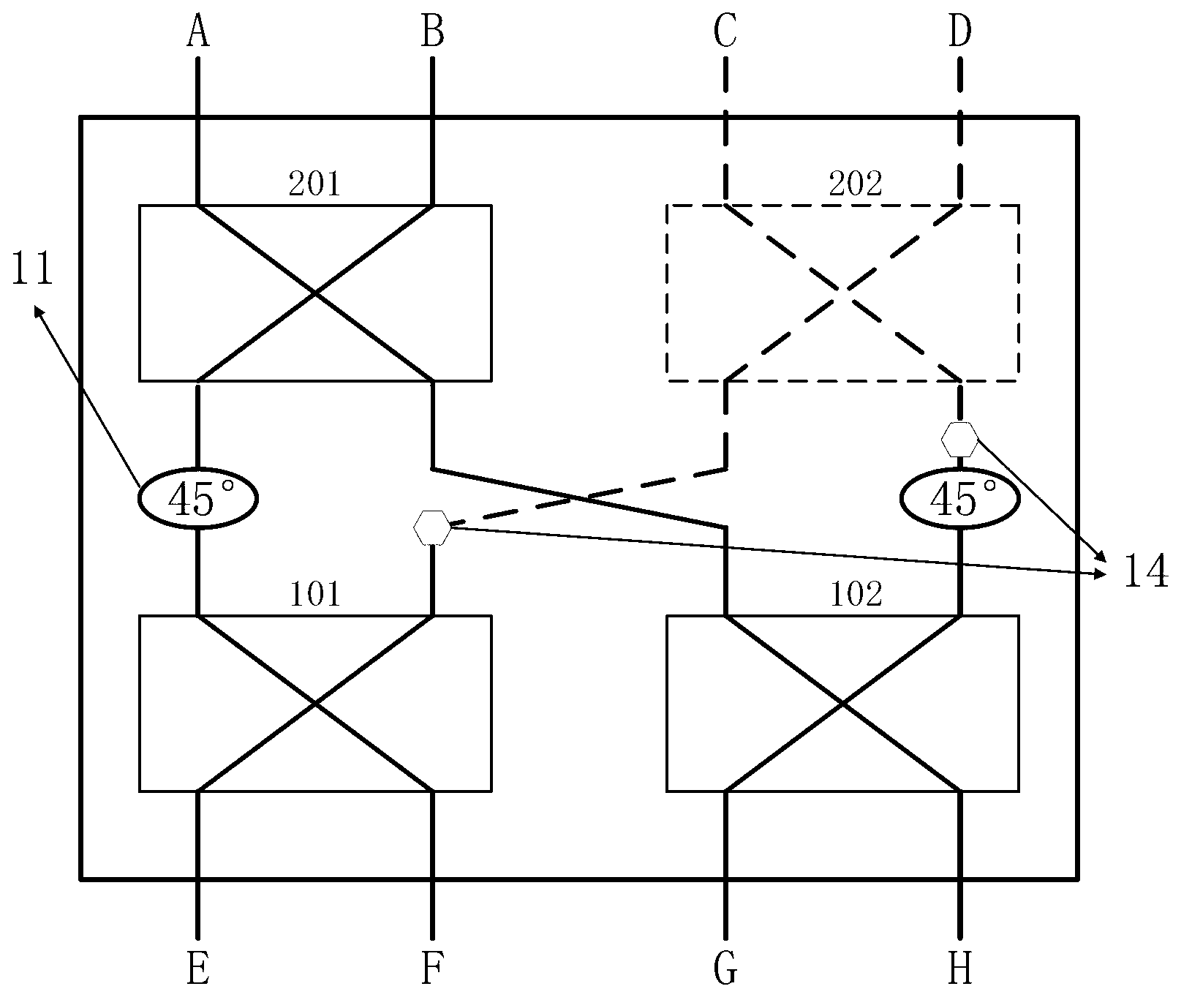

[0020] figure 1 What is shown is the existing conventional 4×4Butler matrix feed network, and all its components are on one plane. The 4×4 Butler matrix feed network includes 8 ports A, B, C, D, E, F, G, H, two 45° fixed phase shifters 11, and four 3db directional couplers with 90° phase shift characteristics 12. Four 3db directional couplers 12 with 90-degree phase shift characteristics are divided into two groups, the lower two form the first group of 3-decibel 90-degree directional couplers, and the upper two form the second group of 3-decibel 90-degree directional couplers. One end of the first set of 3dB 90° directional couplers is connected to the antenna unit, and the other end is connected to the second set of 3dB 90° directional couplers; one end of the second set of 3dB 90° directional couplers is connected to the beam port, and the other end is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com