Five-phase fault-tolerant permanent magnet planetary gear motor for hybrid electric vehicle and operation method of five-phase fault-tolerant permanent magnet planetary gear motor

A technology for hybrid electric vehicles and planetary gears, which is applied to the arrangement of multiple different prime movers and power plants of electric vehicles and general power plants, and can solve problems such as the inability to realize the synthesis and distribution of power sources, and the difficulty of hybrid electric vehicles. Achieve the effect of transmission efficiency and high torque density, low emission and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

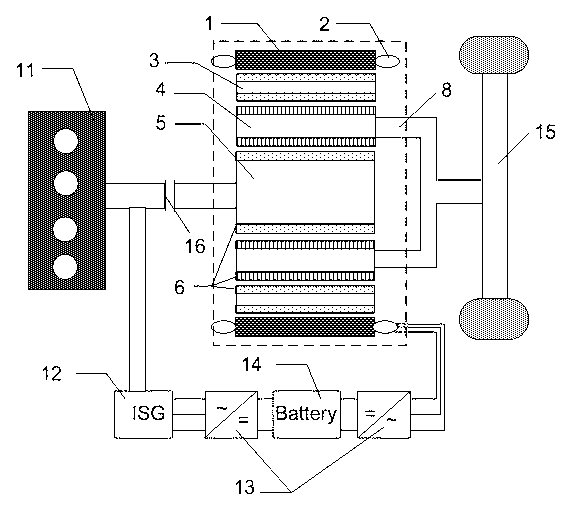

[0025] The present invention combines the theory of non-contact permanent magnet gear transmission with high torque density and high performance permanent magnet drive motor, and adopts a highly fault-tolerant winding connection method, so that the motor can achieve high torque density, high power, The state of high reliability allocates the mechanical power flow and electric power flow of the whole hybrid system to ensure the low emission and high efficiency operation of the whole locomotive.

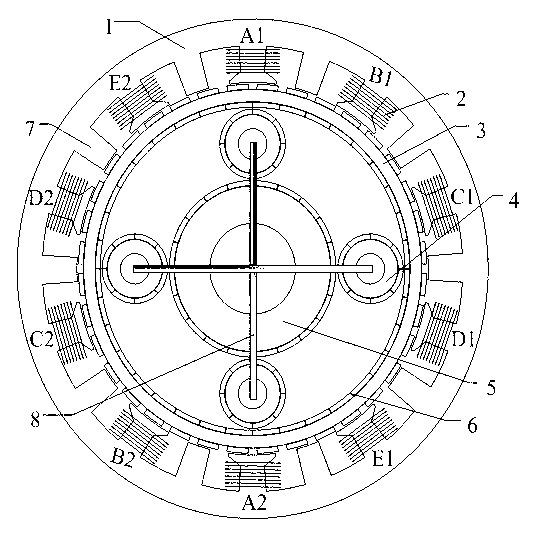

[0026] see figure 1 In the five-phase fault-tolerant permanent magnet planetary gear motor used in the hybrid electric vehicle of the present invention, the outermost ring of the motor is the stator 1, and the coaxial permanent magnet ring gear 3 and the permanent magnet sun gear 5 are sequentially sleeved in the stator 1. The stator 1 is formed by laminating 0.35mm silicon steel sheets. The number of stator slots is 20, and there is only one phase of armature winding 2 in each slot, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com