Method for processing an inner face of a housing having an opening

A shell and tool technology, applied in tool holders, manufacturing tools, metal processing, etc., can solve the problems of high dimensional accuracy and surface quality, huge machine tool load, and cost-intensive, and achieve high dimensional accuracy and surface quality, high precision Processing, Advantages Effects of Processing Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

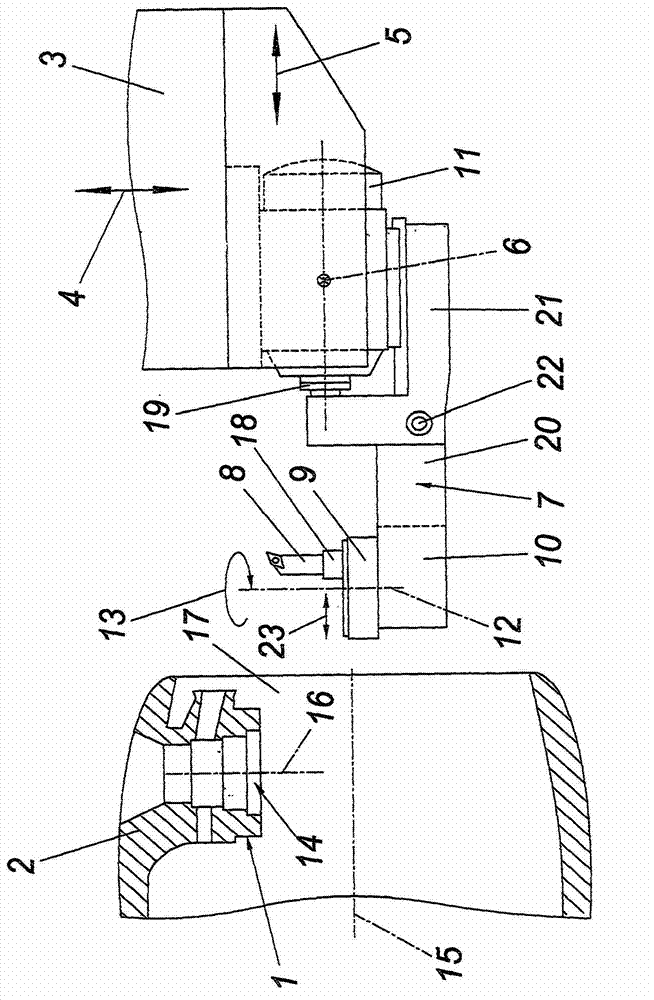

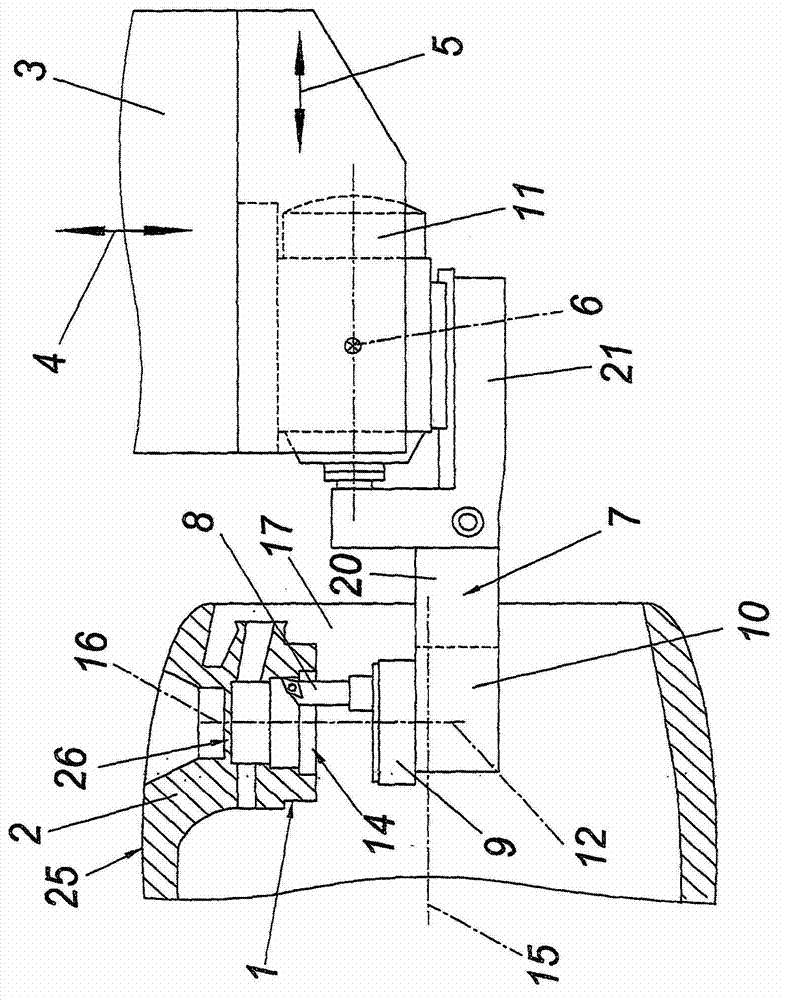

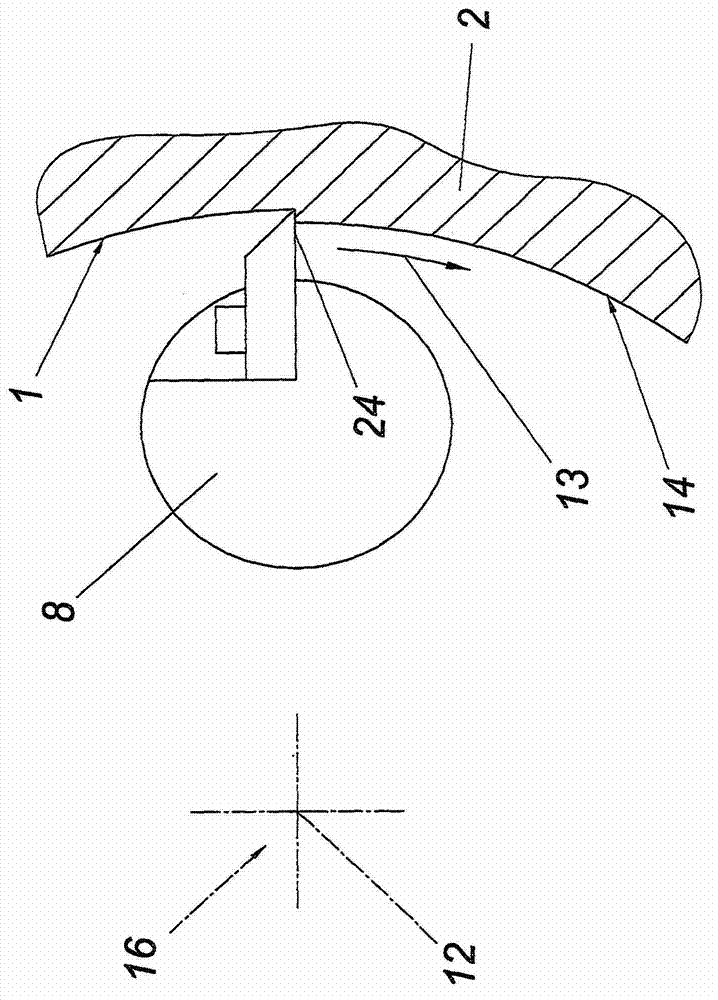

[0019] according to figure 1 , figure 2 with image 3 , describes the method according to the invention by way of example. according to figure 1 , shows the inner side 1 of the housing 2 of the power unit, which is clamped firmly for machining on a machine tool 3 which is only partially shown. The machine tool 3 has a plurality of axes 4 , 5 and 6 , wherein the axes 4 and 5 represent linear axes and the axis 6 represents a rotational axis and a displacement axis, by means of which the tool holder 7 can be moved. A tool 8 is arranged on the tool holder 7 , in particular a turning tool, an internal turning tool, a boring tool or a boring head for machining the inner side 1 . The tool is introduced into the housing 2 through the opening 17 of the housing 2 by displacement of the tool holder 7 along the axes 4 , 5 , 6 , in particular without contact. Damage to the inner side of the housing caused by the tool holder 7 can thus be avoided. In order to enable an advantageous m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com