Method for treating titanium tetrachloride-containing waste liquid

A titanium waste liquid, a certain amount of technology, applied in the field of titanium-containing waste liquid treatment, can solve the problems of increasing the difficulty of waste water treatment, and achieve the effects of reducing the amount of waste treatment, saving treatment costs, and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

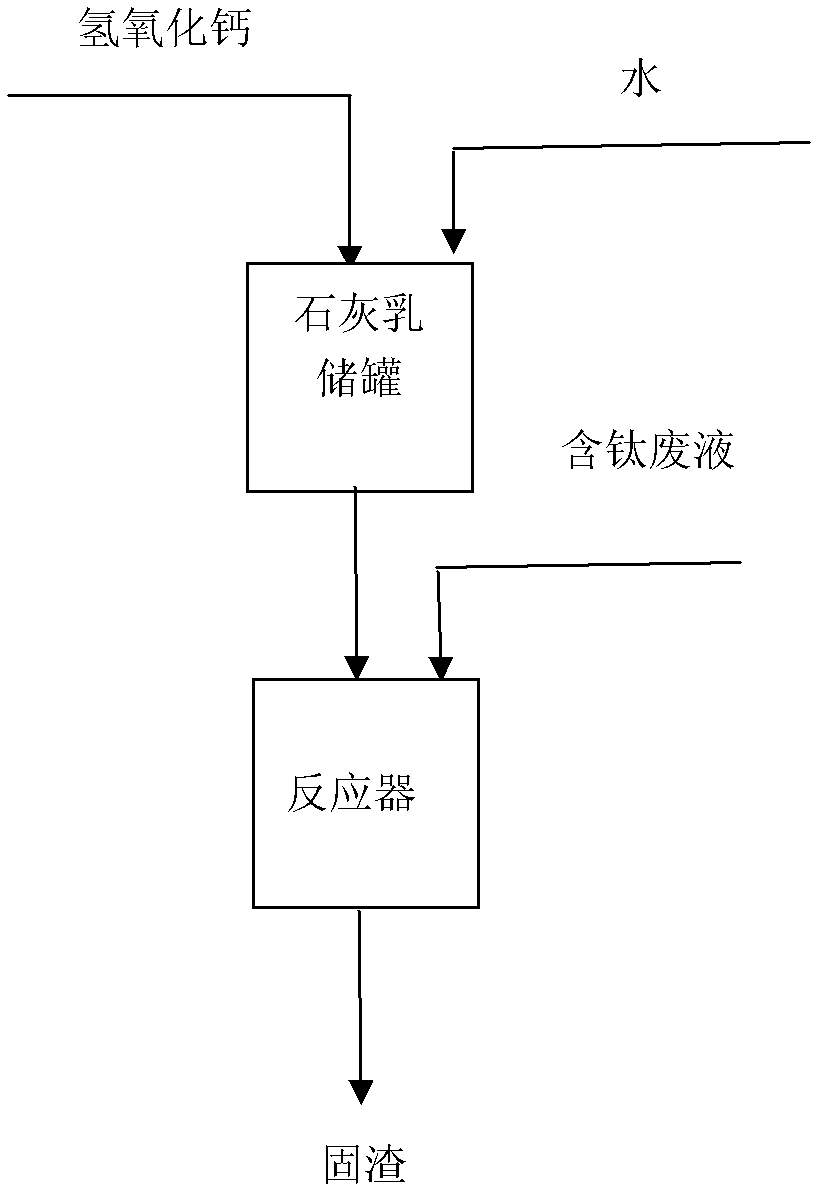

Image

Examples

Embodiment 1

[0022] Mix 100g of slaked lime and 100g of water in a lime milk storage tank to make lime milk, then add the lime milk into the kneader first, then add 100g of titanium-containing waste liquid into the kneader, and mix well. The reactor adopts a water jacket to lower the temperature, and the addition rate of the titanium-containing waste liquid is controlled so that the temperature during the reaction does not exceed 80°C. After the reaction is completed, 300g of solid residue is finally formed, which can be further disposed of.

Embodiment 2

[0023] Embodiment 2: 100g slaked lime is mixed with 100g water in the milk of lime storage tank, is configured into milk of lime, then first milk of lime is joined in the screw mixer, then 50g titanium-containing waste liquid is added in the screw mixer, And stir well. The spiral mixer adopts a water jacket to cool down, and controls the addition speed of the titanium-containing waste liquid so that the temperature during the reaction does not exceed 80°C. After the reaction is completed, 250 g of solid residue is finally formed, which can be further disposed of.

Embodiment 3

[0024] Implementation 3: Mix 100g of slaked lime and 100g of water in a lime milk storage tank to prepare lime milk, then first add the lime milk into the kneader, then add 150g of titanium-containing waste liquid into the kneader, and mix thoroughly uniform. The kneader adopts a water jacket to lower the temperature, and controls the addition rate of the titanium-containing waste liquid so that the temperature during the reaction does not exceed 90°C. After the reaction is completed, 350 g of solid residue is finally formed, which can be further disposed of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com