Optimization method of hot strip rolling production process control system

A technology of production process control and optimization method, applied in rolling force/roll gap control, metal rolling, metal rolling, etc., can solve problems such as production practical considerations, achieve improved control accuracy, control system optimization, considerable economical The effect of value and utility value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

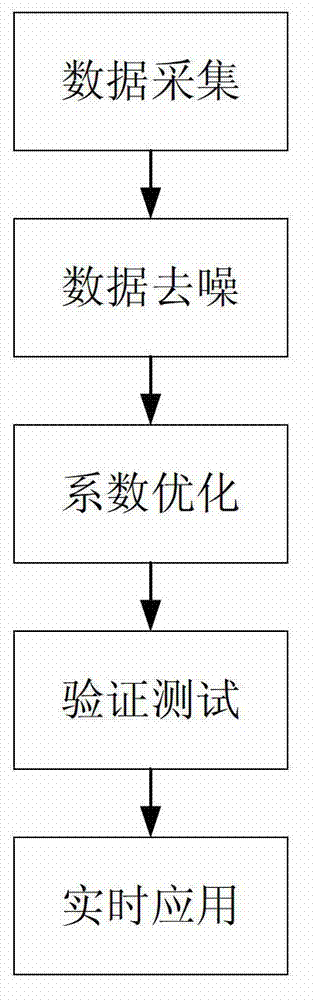

[0035] Such as figure 1 Shown, step a, collecting data. During the rolling process, the historical data collected by the primary machine is stored in the data center, and .mat files (data files readable by MATLAB) are generated through classified collection, and tt_data_*.mat files are generated. In order to make the data representative, if the coefficient is for the steel family or steel type, at least 2000 coils of the same steel family or steel type must be taken, generally 4000 coils; if the global coefficient optimization is selected, there is no need to distinguish steel type.

[0036] Step b, data denoising. In order to improve the reliability of the data, preprocess the selected data, and use simple statistical methods to remove the noise in the data, that is, unreliable data, such as data afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com