Oily wastewater treatment device and treatment method in steel industry

A wastewater treatment and industry technology, applied in the field of oily wastewater treatment devices, can solve the problems of unstable composition, intermittent sources, and inability to mass-produce, and achieve the effects of advanced technical solutions, water conservation, and simple treatment processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

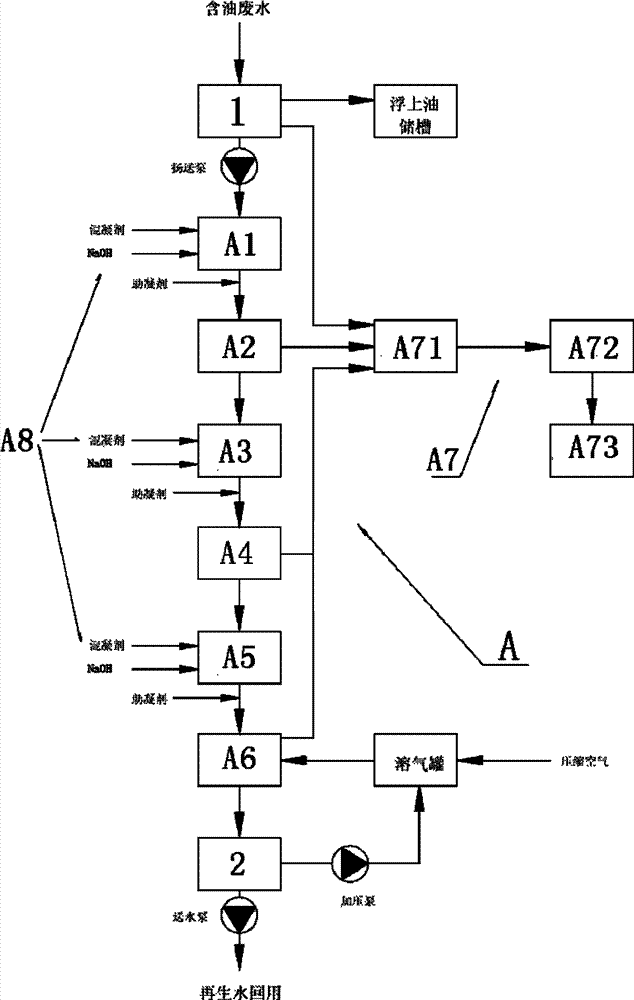

[0043] As shown in Figure 1, the oily waste water first enters the adjustment tank 1 for natural precipitation, and the floating oil on the surface is sent to the floating oil storage tank through the oil collection device; the sludge sinks to the bottom of the tank, and is sent to the scum treatment system through the mud suction device A7's scum storage tank A71.

[0044] The effluent is sent to the primary reaction flocculation tank A1 of the oily wastewater treatment device A through the lifting pump, and the oily wastewater is added to the coagulant PAC, the coagulant aid PHP, and the water quality regulator NaOH through the dosing system A8 in the primary reaction flocculation tank , the mixing reaction is carried out under the agitation of the mixer, and coarse alum flowers have gradually formed at the outlet of the first-stage reaction flocculation tank, and enter the vortex concave aeration and air flotation device A2 under the action of gravity flow. In the aeration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com