Drawing method for automatically controlling cutoff wavelength and control system

A technology of cut-off wavelength and wire drawing, applied in the field of optical fiber manufacturing, can solve problems such as hysteresis, and achieve the effect of reducing tension, realizing automatic adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

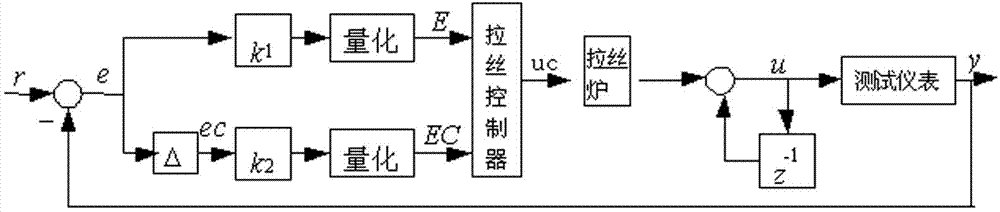

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

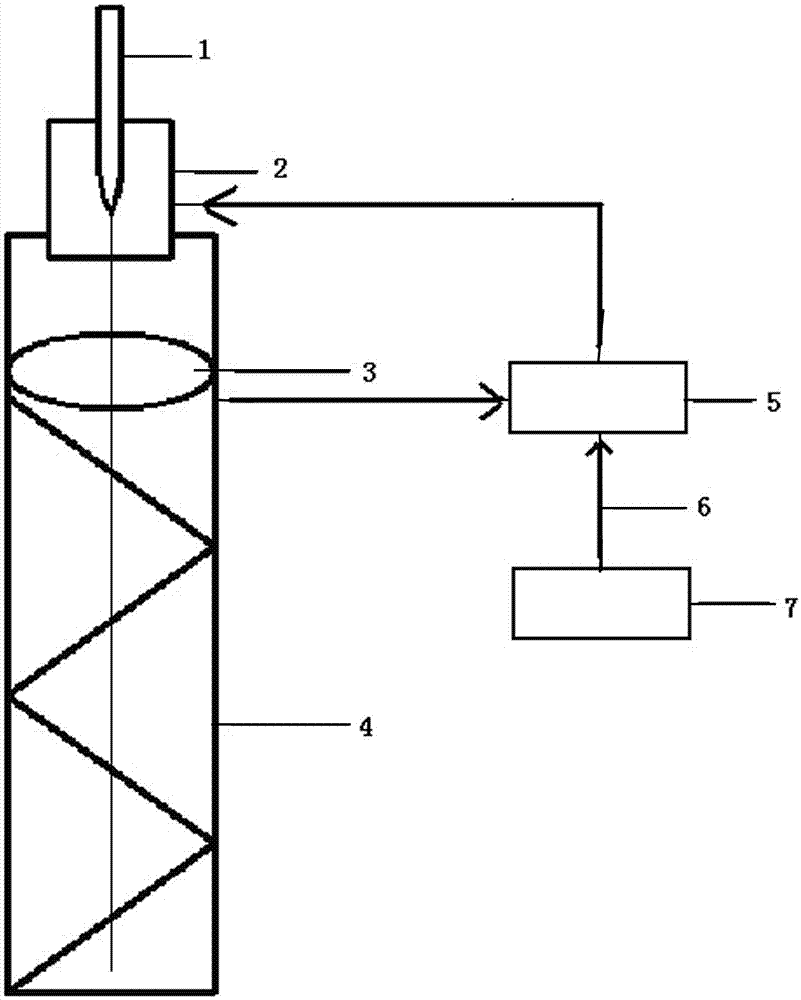

[0024] Refer to attached figure 1 , 2 , a control system for automatically controlling the cut-off wavelength drawing method includes an optical fiber preform (1), a drawing furnace (2), a tension testing instrument (3), an optical fiber drawing machine (4), a drawing line controller (5), and a data transmission A network cable (6) and an optical fiber test instrument (7).

[0025] The optical fiber preform (1) is installed on the upper part of the drawing furnace (2). During production, the optical fiber preform (1) is inserted into the hot zone of the furnace cavity of the drawing furnace (2), and the drawing furnace (2) is installed in the fiber drawing machine (4). In the upper part, the optical fiber testing instrument (7) is installed on the side of the optical fiber drawing machine (4), and the optical fiber produced by the optical fiber drawing machine is measured at the optical fiber testing instrument. On the wire drawing machine (4), the optical fiber test instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com