Method for producing isopropanol by liquid-phase hydrogenation of acetone

A technology of isopropanol and acetone liquid, applied in the field of isopropanol production by liquid phase hydrogenation of acetone, can solve the problems of high catalyst price and high reaction pressure, and achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

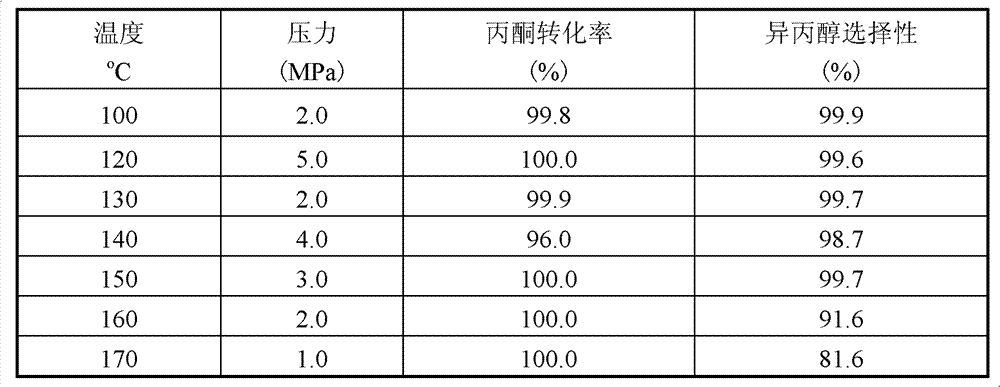

Examples

Embodiment 1

[0014] Catalyst 1: will be made of 5.0g Mg(NO 3 ) 2 .6H 2 A solution composed of O and 10.0 g of water is impregnated on 10.0 g of alumina powder by equal-volume impregnation, then dried at 120 ° C, and roasted at 1100 ° C to obtain a catalyst carrier, which is mixed with 50.0 g of water and beaten to obtain slurry I , the solution composed of 18.0g nickel nitrate hexahydrate solution, 68.0g sodium carbonate and 100.0g water will be dropped into the slurry I for reaction at the same time. After aging for 2 hours, the precipitate was washed and filtered, dried at 120°C for 12 hours, calcined at 400°C for 4 hours, and then pressed into tablets to obtain Catalyst 1, whose composition was 30%NiO-5%MgO-65%Al 2 o 3 . Take 3.0g of the catalyst, 20.0g of acetone, and 100.0g of isopropanol, and carry out hydrogenation reaction of acetone in a 300ml autoclave. The reaction temperature is 120°C, the reaction pressure is 4.0MPa, and the reaction time is 4.0h. The reaction results are ...

Embodiment 2~10

[0015] Examples 2-10 (catalysts 2-10), the catalysts were prepared according to the steps in Example 1, only the composition of the materials was changed, and the composition of the materials of the catalysts is shown in Table 1. Take 3.0g of catalyst catalyst, 20.0g of acetone, and 100.0g of isopropanol, and carry out acetone hydrogenation reaction in a 300ml autoclave for acetone hydrogenation reaction. The reaction temperature is 120°C, the reaction pressure is 4.0MPa, and the reaction time is 4.0h. The reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com