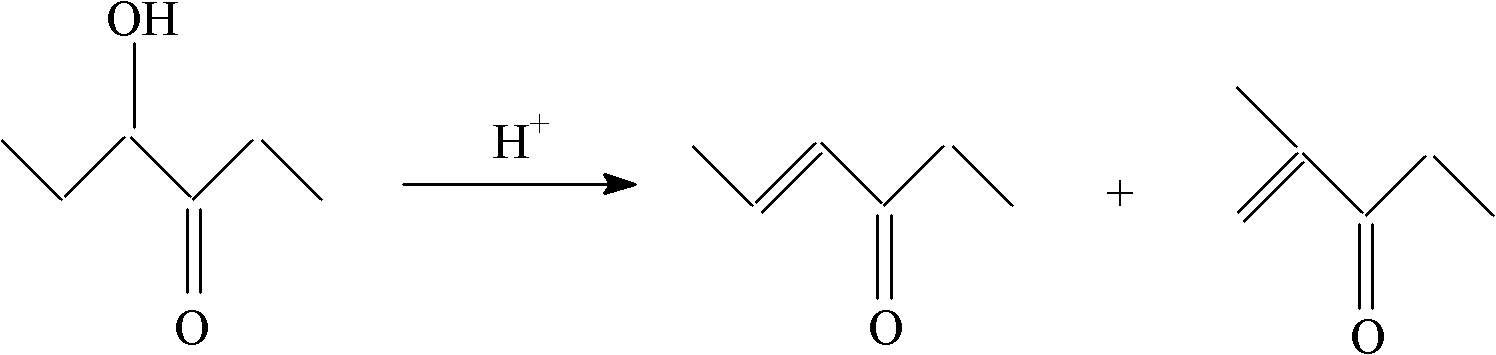

Method of 4-hydroxy-3-hexanone catalytic dehydration

A technology for catalytic dehydration and hexanone, applied in chemical instruments and methods, molecular sieve catalysts, carbon-based compound preparation, etc., can solve the problems of high reaction temperature, low space velocity, and poor catalyst activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

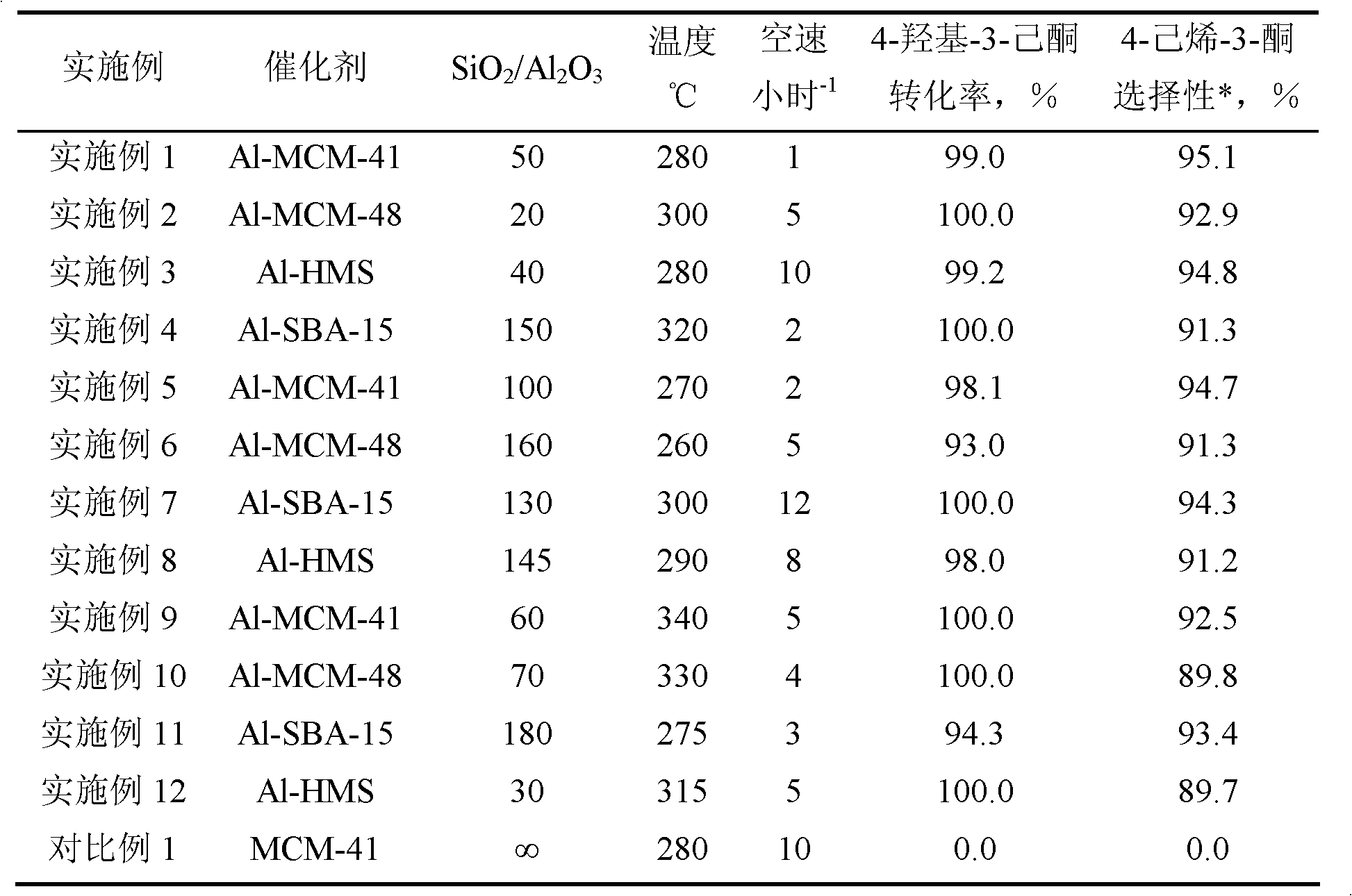

Embodiment 1

[0014] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at normal pressure. A stainless steel reactor with an inner diameter of 10 mm was used. The loading amount of the catalyst was 10 ml, the reaction temperature was 350 °C, and the liquid space velocity was 1 hour. -1 , reacted under normal pressure. Reaction product analysis adopts HP 6890 gas chromatography, hydrogen flame detector, HP-6 capillary column (60m * 0.25mm * 0.25μm), catalyst is Al-MCM-41, its SiO 2 / Al 2 o 3 The molar ratio was 50. The reaction results are shown in Table 1.

Embodiment 2~12

[0016] According to each step of [embodiment 1], just catalyzer adopts different catalyzer, and concrete test condition and reaction result are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com