Design method for noise-absorption metal fibrous porous material, metal fibrous porous material and preparation method thereof

A metal fiber, porous material technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of high cost, the sound absorption performance of metal fiber porous materials, and the optimal sound absorption performance of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] 1. Determine the optimum porosity of the material

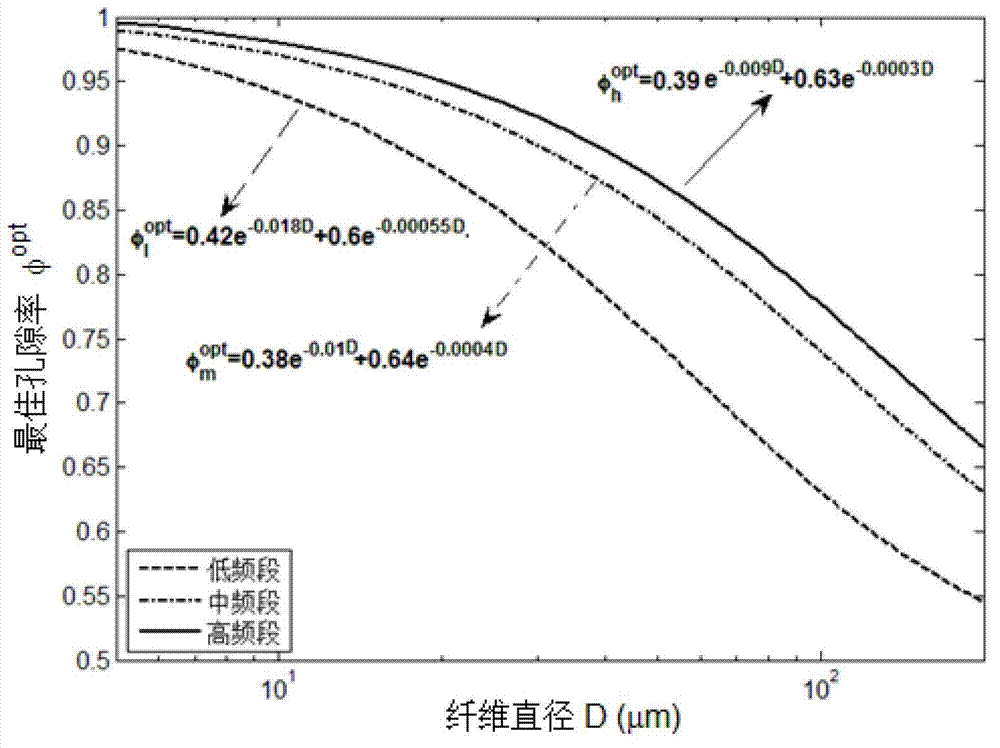

[0086] When the thickness of the metal fiber porous material is 25mm, through the above optimization algorithm, the optimal porosity φ of the material is established opt ( and respectively represent the curve relationship between the optimal porosity values in low, medium and high frequency bands) and fiber diameter D (such as figure 1 shown):

[0087] In the case of low frequency (20 ~ 500Hz): φ l opt = 0.42 e - 0.018 D + 0.6 e - 0.00055 D

[0088] In the case of intermediate frequency (greater than 500 ~ 2000Hz): φ m opt = 0.38 e - 0.01 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com