PA56 film composite broadband sound absorption material, and preparation method and application thereof

A sound-absorbing material and membrane composite technology, applied in the field of sound-absorbing materials, can solve the problems of being too soft, thick, affecting installation and use, etc., and achieve the effects of increasing bulkiness, simple processing technology, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

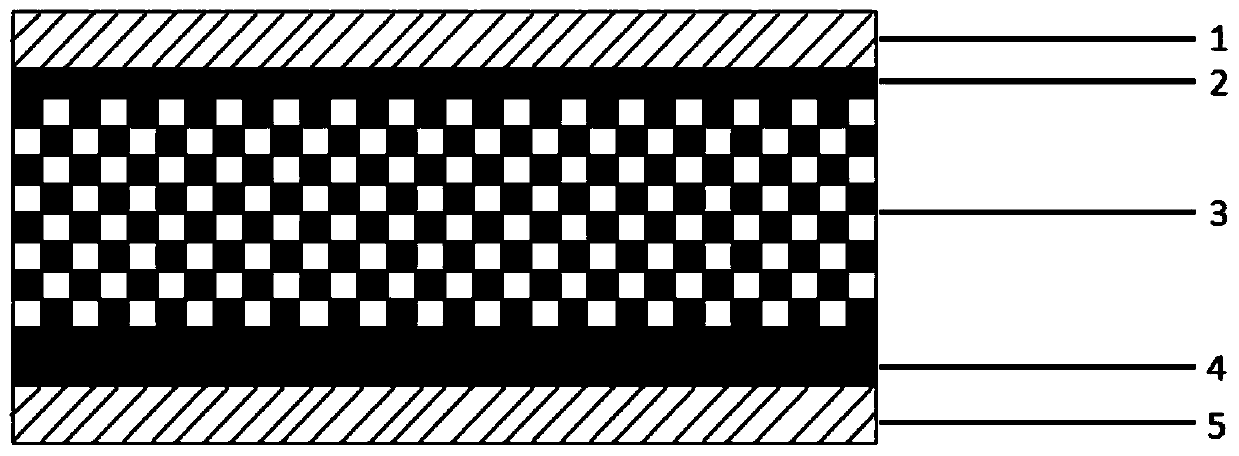

[0042] Such as figure 1 As shown, a PA56 film composite broadband sound-absorbing material, the sound-absorbing material is composed of PA56 electrospun fiber film 1, PP melt-blown fiber layer 2, polyester needle-punched layer 3, PP melt-blown fiber layer 4 from top to bottom , PA56 electrospun fiber membrane 5.

[0043] The PA56 electrospun fiber membrane on the top layer and the bottom layer is PA56 electrospun membrane after dissolving in formic acid / acetic acid system, and the electrospinning machine is jetted to form a PA56 electrospun membrane. The average pore size is 260nm, and a large number of nano spider webs can be seen under SEM. The average fiber diameter is 320 nm. The upper and lower film thicknesses are both 0.2mm. 2. The 4-layer PP melt-blown fiber layer is a mixture of melt-blown fiber and mechanical carding, laying and spinning. The thickness of the two layers of melt-blown fiber layer is 2mm, and its surface density is 500g / m 2 . The polyester needled ...

Embodiment 2

[0053] Such as figure 1 As shown, a PA56 film composite broadband sound-absorbing material, the sound-absorbing material is composed of PA56 electrospun fiber film 1, PP melt-blown fiber layer 2, polyester needle-punched layer 3, PP melt-blown fiber layer 4 from top to bottom , PA56 electrospun fiber membrane 5.

[0054] The PA56 electrospun fiber membrane on the top layer and the bottom layer is PA56 electrospun membrane formed by jetting through an electrospinning machine after PA56 is dissolved in a formic acid / acetic acid system. The average pore size is 200nm, and a large number of nano cobwebs can be seen under SEM. The average diameter of the fiber is 290nm, and the thickness of the two layers of film on the upper line is 0.3mm. 2. The 4-layer PP melt-blown fiber layer is a mixture of melt-blown fiber and mechanical carding, laying, and spinning. The thickness of the two melt-blown fiber layers is 3mm, and the surface density is 630g / m 2 . The polyester needled lay...

Embodiment 3

[0064] Such as figure 1 As shown, a PA56 film composite broadband sound-absorbing material, the sound-absorbing material is composed of PA56 electrospun fiber film 1, PP melt-blown fiber layer 2, polyester needle-punched layer 3, PP melt-blown fiber layer 4 from top to bottom , PA56 electrospun fiber membrane 5.

[0065] The PA56 electrospun fiber membrane on the top layer and the bottom layer is PA56 electrospun membrane formed by jetting through an electrospinning machine after PA56 is dissolved in a formic acid / acetic acid system. The average pore size is 170nm, and a large number of nano cobwebs can be seen under SEM. The average fiber diameter was 210 nm. The thickness of the two layers of film on the upper line is 0.1 mm. 2. The 4-layer PP melt-blown fiber layer is a mixture of melt-blown fiber and mechanical carding, laying and spinning. The thickness of the two layers of melt-blown fiber layer is 1.5mm, and its surface density is 320g / m 2 . The polyester needled l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com