Preparation of pH-controlled-release long-acting intelligent corrosion inhibitor

A technology of controlled release and corrosion inhibitors, applied in the field of preparation of long-acting intelligent corrosion inhibitors, to achieve high corrosion inhibition efficiency, good application prospects, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

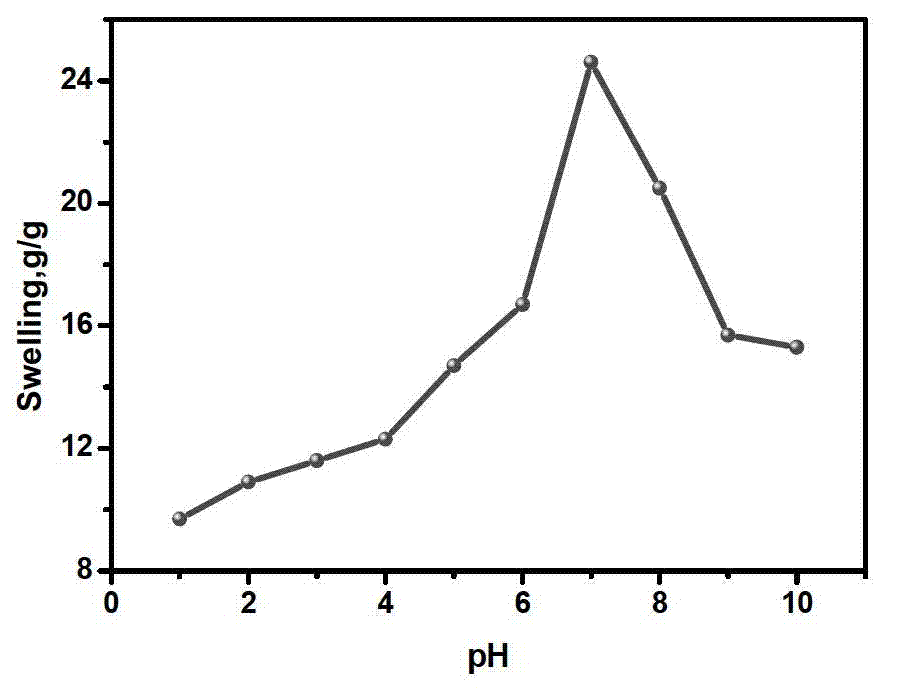

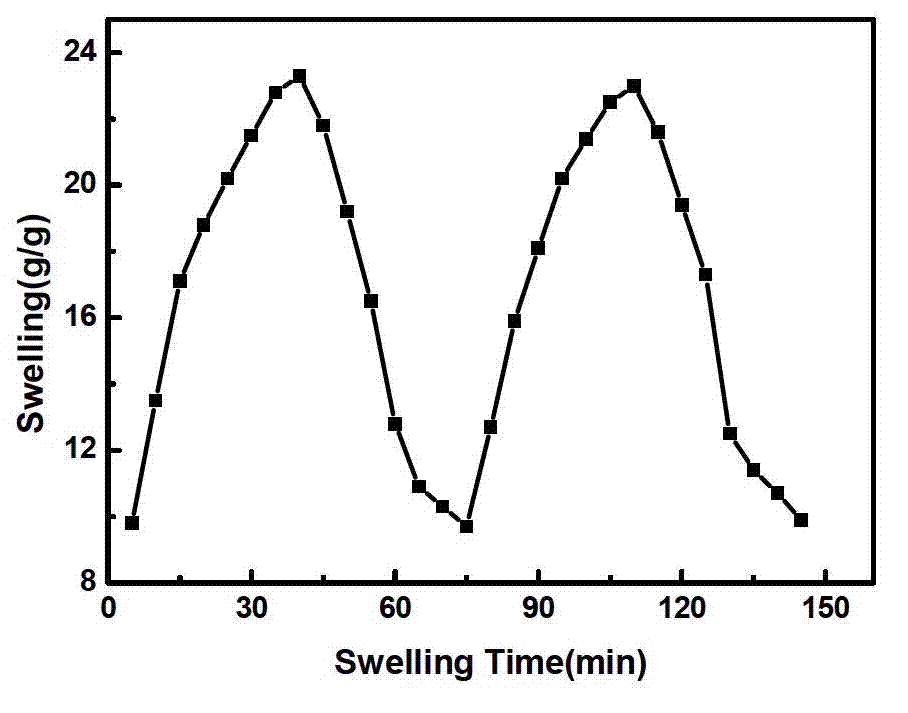

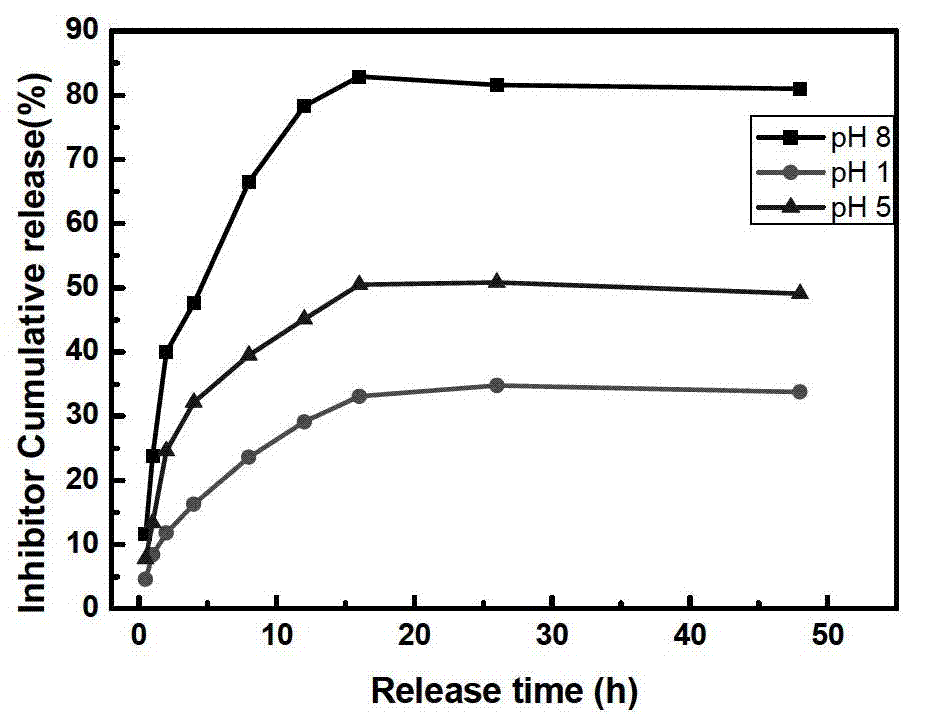

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of pH-sensitive hydrogels

[0035] a) Add 2.0g of starch into a three-necked flask with a condenser, a stirrer and a thermometer, add 35mL of distilled water, blow in nitrogen, stir at 300 rpm, and gradually raise the temperature to 80°C. Dissolve 0.1 g of ammonium persulfate initiator in 5 mL of deionized water, add it into the above-mentioned reactant aqueous solution, and continue to pass nitrogen gas, and the reaction is stable for 10 min. Add 1.5g of acrylic acid and 1.5g of hydroxyethyl methacrylate to the above reactant aqueous solution; add 0.05g of methylenebisacrylamide cross-linking agent to 5mL of deionized water into the above reactant aqueous solution, controlled at React at the above stirring speed and temperature for 60 min.

[0036] b) After the reaction, cool to room temperature and adjust the pH to 8 with 1M NaOH solution. Add 0.05 g of sodium bicarbonate foaming agent, and stir at a speed of 500 rpm until a uniform foam form is ...

Embodiment 2

[0042] 1) Preparation of pH-sensitive hydrogels

[0043]a) Add 1.0g of starch into a three-necked flask equipped with a condenser, a stirrer and a thermometer, add 10mL of distilled water, blow in nitrogen, stir at a speed of 300 rpm, and gradually raise the temperature to 70°C. Dissolve 0.03g of ammonium persulfate initiator in 3mL of deionized water, add it into the above-mentioned reactant aqueous solution, continue to pass nitrogen, and the reaction is stable for 10min. Add 1g of acrylic acid and 1g of hydroxyethyl methacrylate to the above reactant aqueous solution; add 0.03g of methylenebisacrylamide crosslinking agent to 3mL of deionized water into the above reactant aqueous solution, and control the above stirring React at speed and temperature for 100 min.

[0044] b) After the reaction, cool to room temperature and adjust the pH to 8 with 1M NaOH solution. Add 0.05 g of sodium bicarbonate foaming agent, and stir at a speed of 500 rpm until a uniform foam form is pr...

Embodiment 3

[0049] 1) Preparation of pH-sensitive hydrogels

[0050] a) Add 2.0g of starch into a three-necked flask equipped with a condenser, a stirrer and a thermometer, add 20mL of distilled water, blow in nitrogen, stir at 300 rpm, and gradually raise the temperature to 100°C. Dissolve 0.3g of ammonium persulfate initiator in 5mL of deionized water, add it into the above-mentioned reactant aqueous solution, continue to pass nitrogen, and the reaction is stable for 10min. Add 1.5g of acrylic acid and 1.5g of hydroxyethyl methacrylate to the above reactant aqueous solution; add 0.3g of methylenebisacrylamide cross-linking agent to 5mL of deionized water into the above reactant aqueous solution, and control at React at the above stirring speed and temperature for 150 min.

[0051] b) After the reaction, cool to room temperature and adjust the pH to 8 with 1M NaOH solution. Add 0.05 g of sodium bicarbonate foaming agent, and stir at a speed of 500 rpm until a uniform foam form is produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com