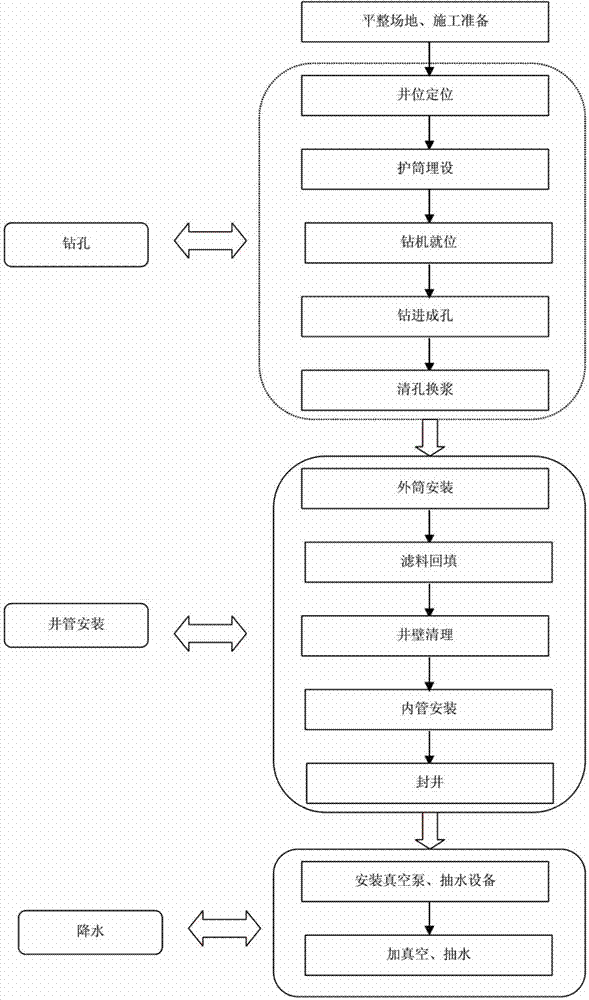

Low-permeability sludge claypan ultra-vacuum dual-pipe unwatering well and construction technology

A low-permeability, silt-based technology, applied in infrastructure engineering, construction, etc., can solve problems such as poor drainage, poor sealing, and insufficient vacuum, and achieve a reduction in the number of layouts, short pre-precipitation time, and water collection. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device and method are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

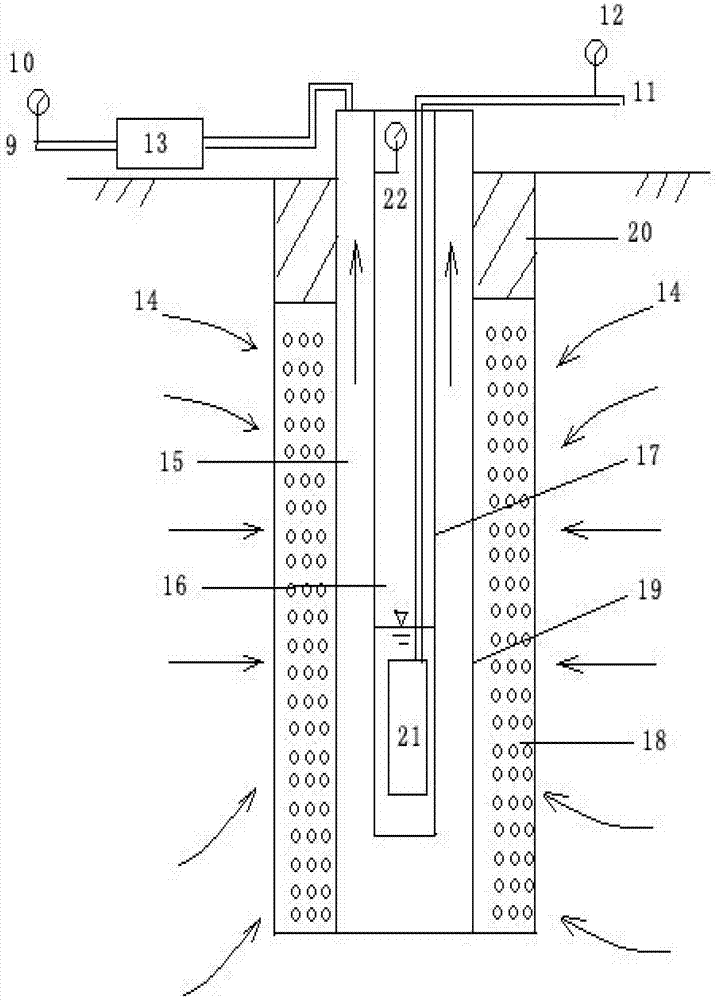

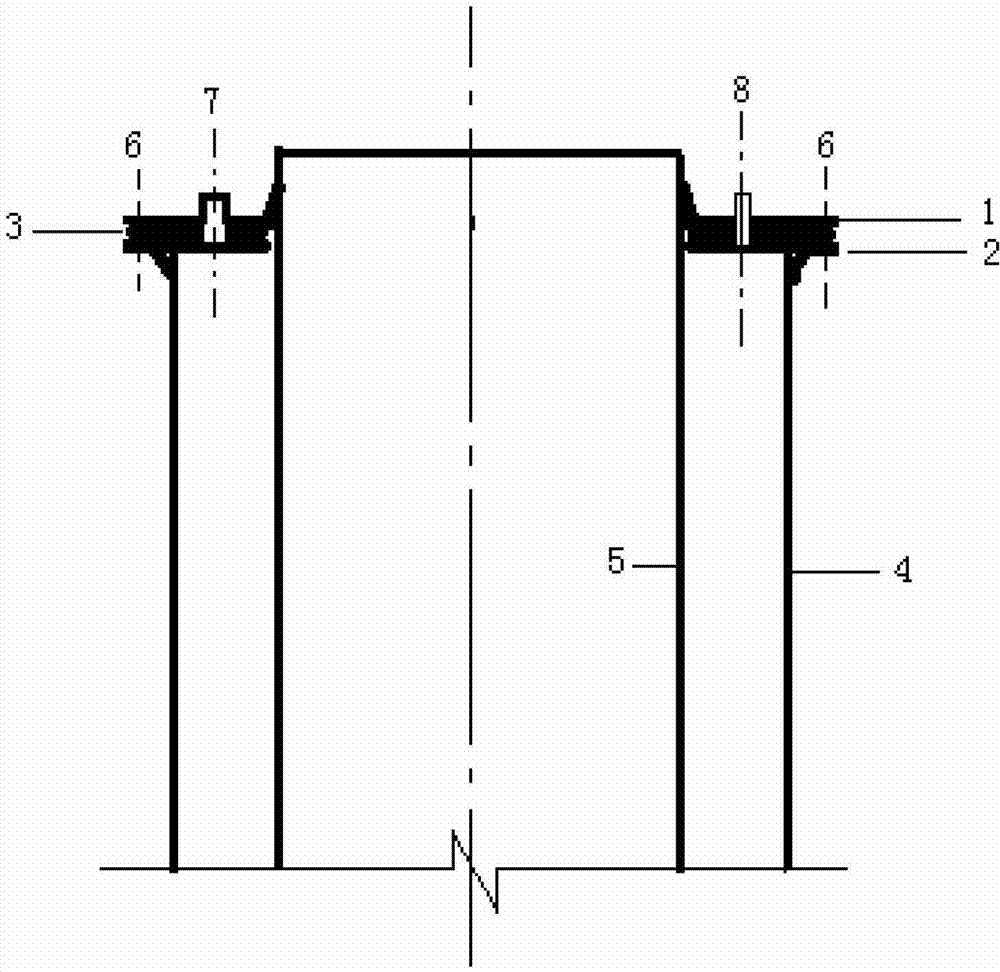

[0035] The hole diameter of the well is greater than or equal to 0.55m. Its shaft structure adopts steel pipe, which is divided into outer pipe and inner pipe. The diameter of the outer pipe is 273mm, and it is composed of a dead pipe and a filter pipe. The upper and lower pipe walls are airtight dead pipes. The length of the upper dead pipe is not less than 4.0m, and the length of the lower pipe is 0.5-1.0m; The water filter pipe of the water filter hole is wrapped with sand mesh around the wall of the water filter pipe, generally 2 layers of 40-60 mesh filter mesh. The top of the outer tube is sealed, and the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com