Tile set having plastic liner

A technology of tile sleeve and inner lining, applied in the field of tile sleeve and bearing sleeve, can solve the problems of high consumption of non-ferrous metal box lubricating oil, short replacement cycle of tile sleeve, large consumption of tile sleeve, etc., and achieves saving metal box lubricating oil, The effect of saving machine maintenance man-hours and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

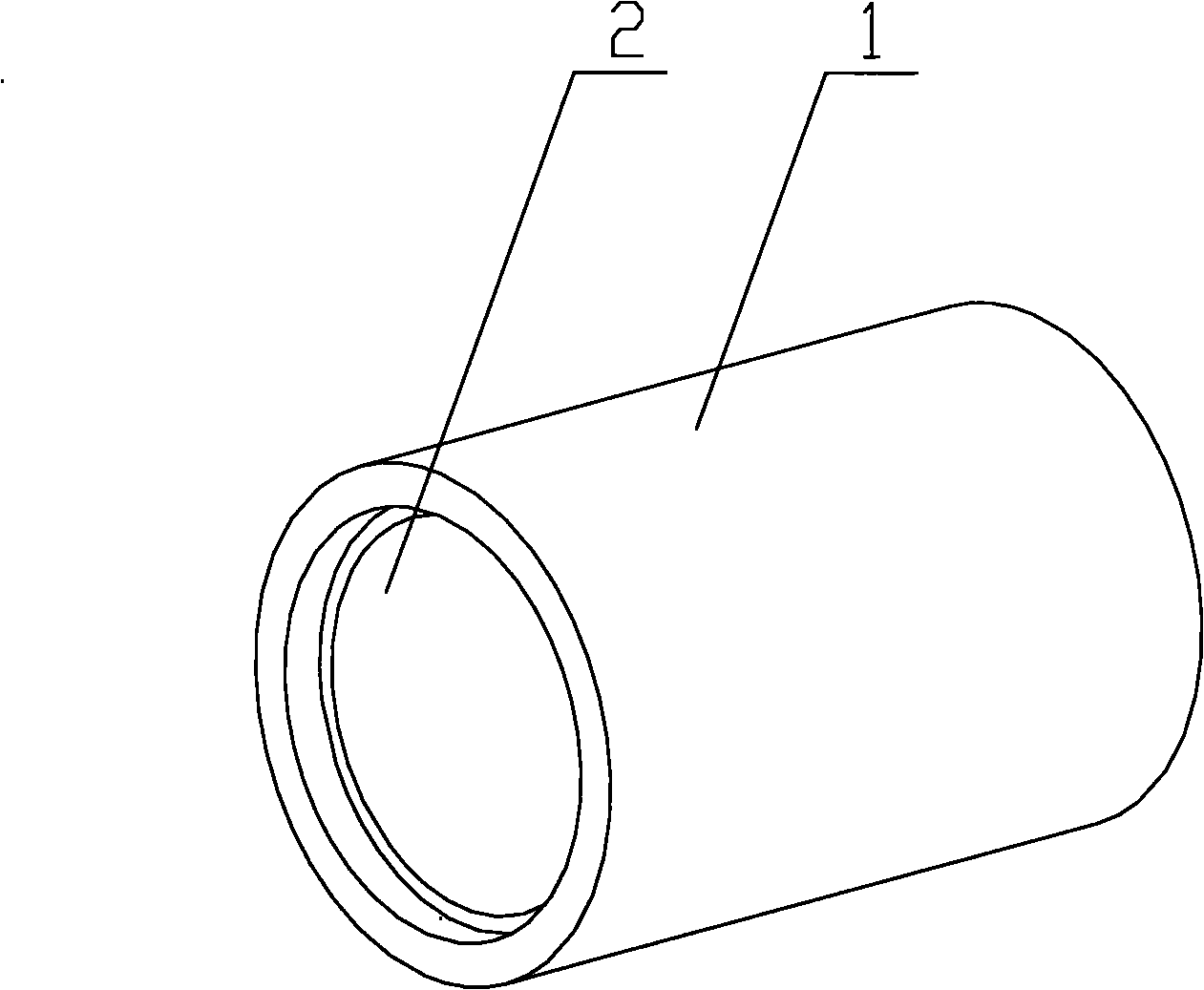

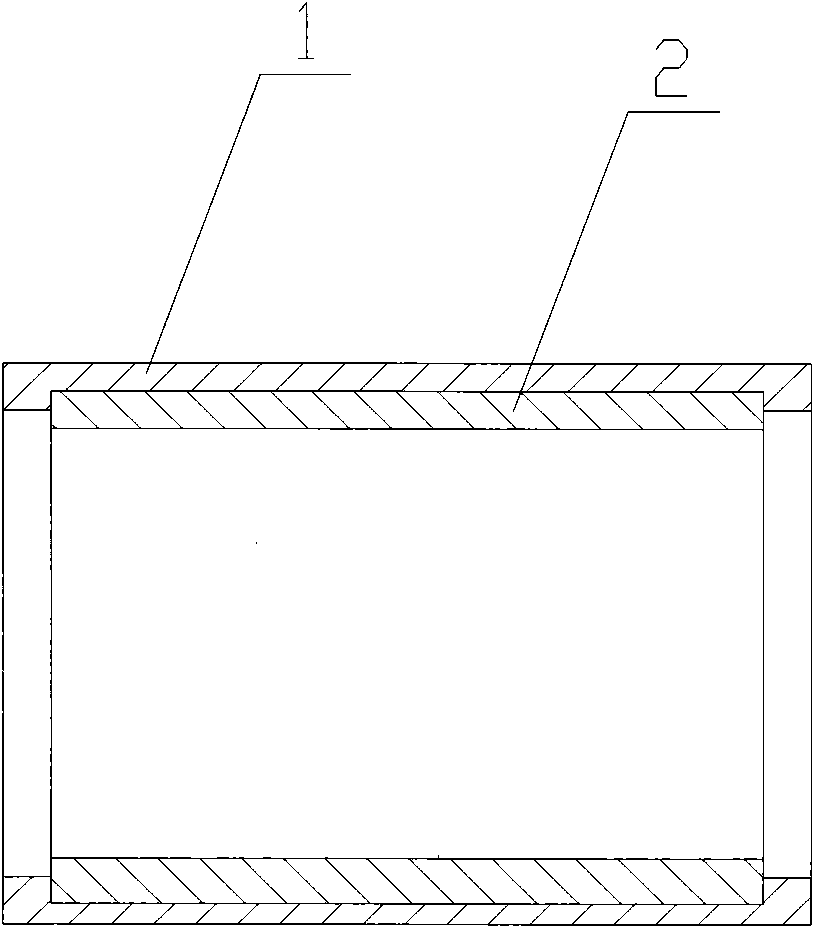

[0012] Such as figure 1 , 2 Shown is a shoe sleeve with a plastic lining according to the present invention, which includes a shoe sleeve body 1 and a bushing 2; the bushing 2 is close to the inner wall of the shoe sleeve body 1; the lining ring 2 is made of metal powder made of epoxy resin; the metal powder is copper powder, accounting for 10%.

[0013] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0014] The shoe sleeve of the invention has small friction coefficient, long service life, no need for oil lubrication, corrosion resistance (except halogen compounds), not easy to creep, can be used in the temperature range of -200°C to 300°C, absorbs vibration, and has low Noise, it is most suitable for light load and low rotation speed. According to the experiment on the textile machine, the service life of the lining ring can reach 2-3 times of the original bushing. When the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap