System and method realizing remote control of on-site equipment through connection of short messages and programmable logic controller (PLC)

A technology of remote control system and field equipment, applied in the direction of electrical program control, telephone communication, comprehensive factory control, etc., can solve the problems of remote control, economic loss, inability to know the working condition of equipment, etc., and achieve the effect of rapid repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

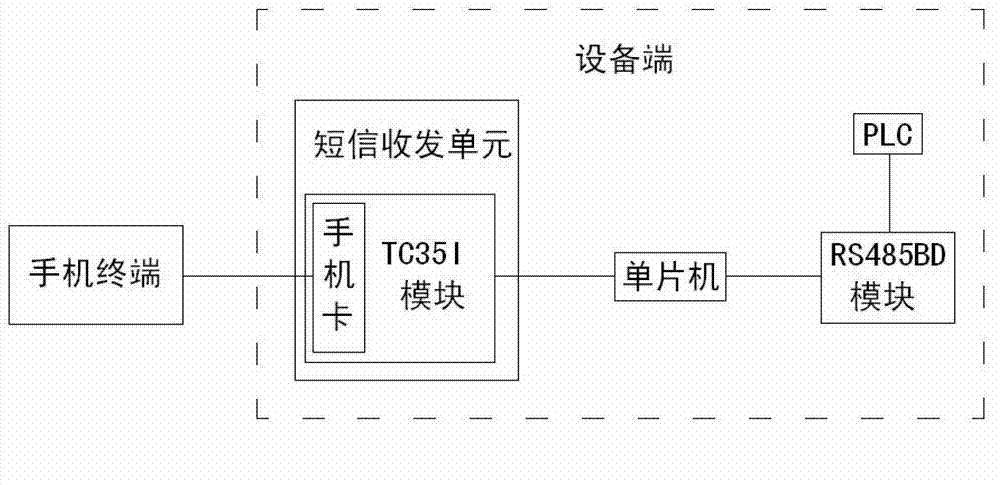

[0026] This embodiment describes a remote control system that realizes field equipment by connecting to PLC through SMS, and its system schematic diagram is as follows figure 1 As shown, it includes a mobile phone terminal and a device-side system. The device-side system includes a PLC for controlling the work of the device, a short message transceiver unit for communicating with the mobile terminal, and a single-chip microcomputer for analyzing the content of the short message. The short message transceiver unit is connected to the single-chip microcomputer. The single chip microcomputer is connected with PLC again.

[0027] The PLC communicates with the serial port of the single-chip microcomputer through the RS485BD module, and the RS485BD module is used for sending and receiving instruction data of the single-chip microcomputer.

[0028] The short message transceiver unit includes a mobile phone card and a TC35I module, the mobile phone card is set in the TC35I module, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com