Submodule unit of voltage source transverter based on full control components

A technology of voltage source converters and sub-modules, applied in output power conversion devices, conversion of AC power input to DC power output, electrical components, etc., can solve the problem of reducing work efficiency and operability, equipment dv/dt stress Large, inconvenient equipment maintenance and other problems, to achieve the effect of convenient installation and transportation, low output voltage change rate, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

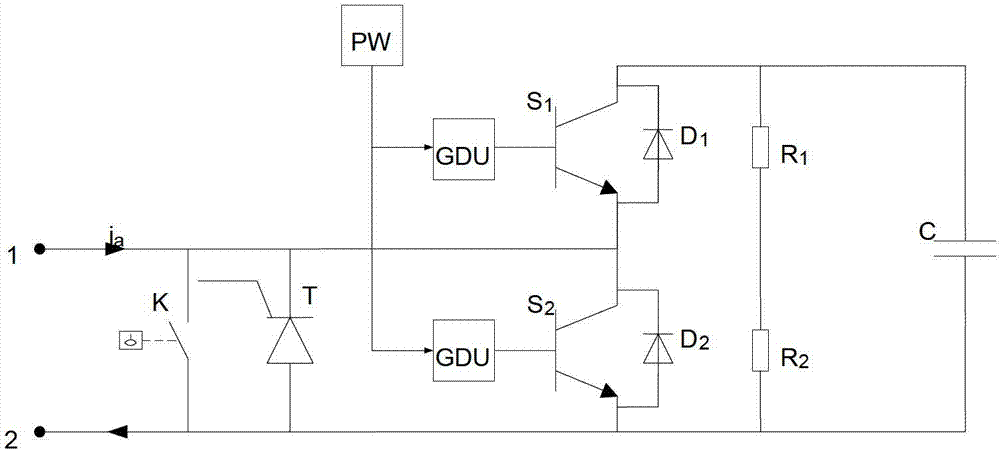

[0042] The sub-module unit of the voltage source converter of this embodiment adopts an independent control mode, and the electrical schematic diagram of the sub-module unit is as follows figure 1 As shown, this is the parallel structure of the IGBT module and the capacitor of the half-bridge structure. In this embodiment, the half-bridge structure or the upper half of the H-bridge structure is defined as the upper-side IGBT module, for example figure 1 The IGBT module composed of the IGBT (S1) and the built-in diode D1 in parallel is the upper tube IGBT module (referred to as the upper IGBT), and the lower part of the half bridge structure or the H bridge structure is the lower tube IGBT module, for example figure 1 The IGBT module composed of the IGBT (S2) and the built-in diode D2 connected in parallel is a lower-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com