Cold-storage agent

A cooling storage agent and drying technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of water absorption deviation, insufficient freezing and cooling performance, unable to become a fully uniform gel, etc., and achieve long maintenance time. , easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0033] [Manufacturing Example 1]

[0034] Inject 12L of ion-exchanged water into the mixing tank (inner capacity 60L) of the vacuum mixing device and add 3kg of powdered sodium carboxymethyl cellulose ("SUNROSE F350HC-4" manufactured by Nippon Paper Co., Ltd.), with water and carboxymethyl The total amount of cellulose was added to 15L. At this time, in order to suppress flying of the powdered sodium carboxymethylcellulose, it was added while spraying water from above the powder. After the raw materials were added, the lid of the vacuum kneading device was closed, and the mixture was stirred in the vacuum kneading device for 40 minutes while performing vacuum suction to prepare a cellulose kneaded product.

[0035] Next, the cellulose kneaded product was molded in a vacuum and irradiated with 14 kGy electron beams to prepare a crosslinked cellulose gel. The cross-linked cellulose gel was transferred to a dryer and dried at about 70°C.

[0036] 55 g (5% of the total amount ...

Embodiment 1

[0040] 1100 g of the cool storage agent prepared in Production Example 1 was filled in a cool storage box (width 19.5 cm x length 26 cm x thickness 3.5 cm), and the freezing time and cold storage time were measured.

[0041]

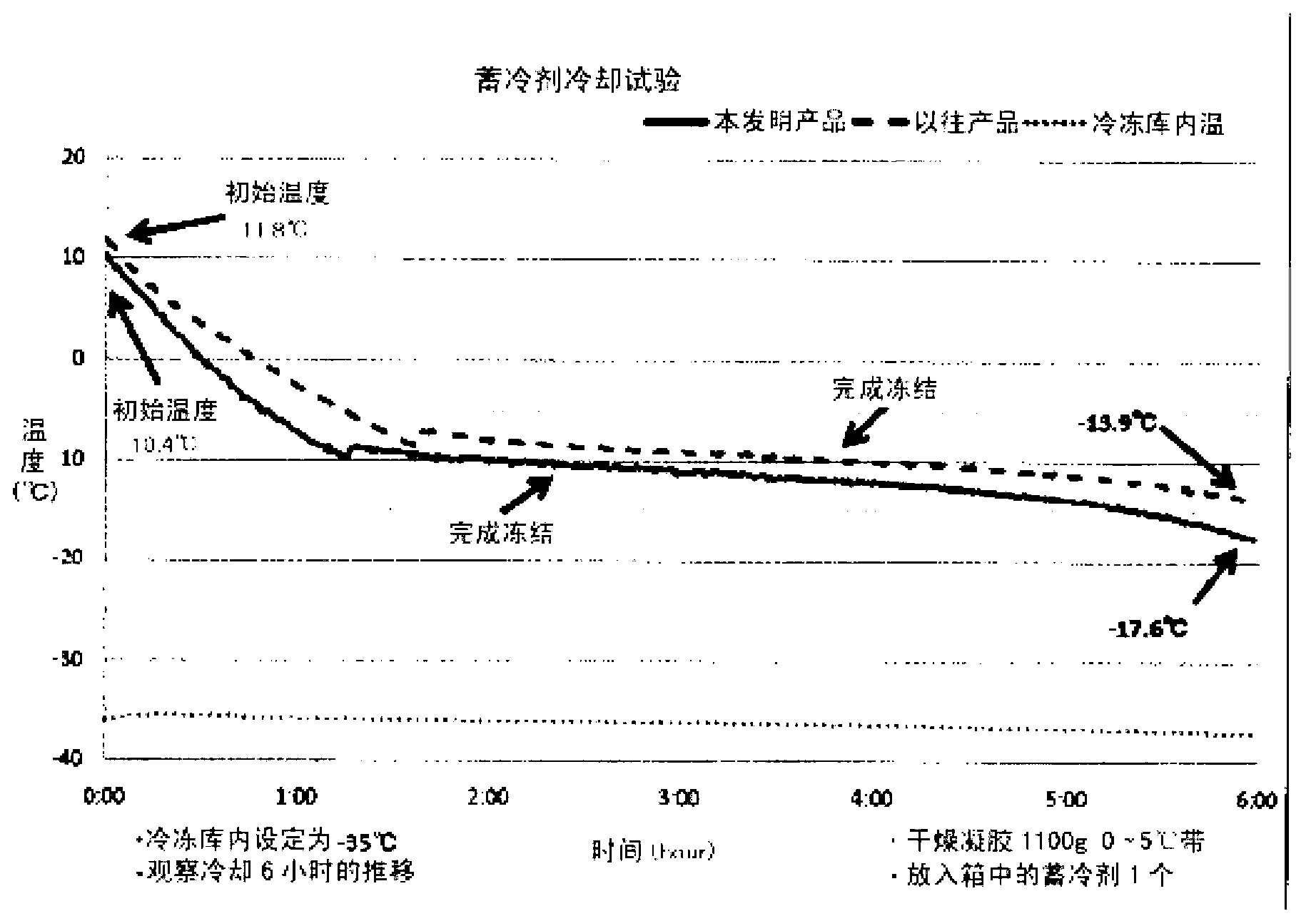

[0042] After the cooling storage box was left at room temperature, it was placed in a fanless freezer at -35°C to cool for 24 hours, and the time required for freezing was measured. The results are shown in figure 1 .

[0043] The initial temperature of the cold storage agent is 10.4°C. About 1 hour and 10 minutes after it is placed in the freezer, the temperature of the cold storage agent drops sharply to -10°C, completes freezing in about 2 hours and 20 minutes, and reaches -17.6°C after 6 hours.

[0044]

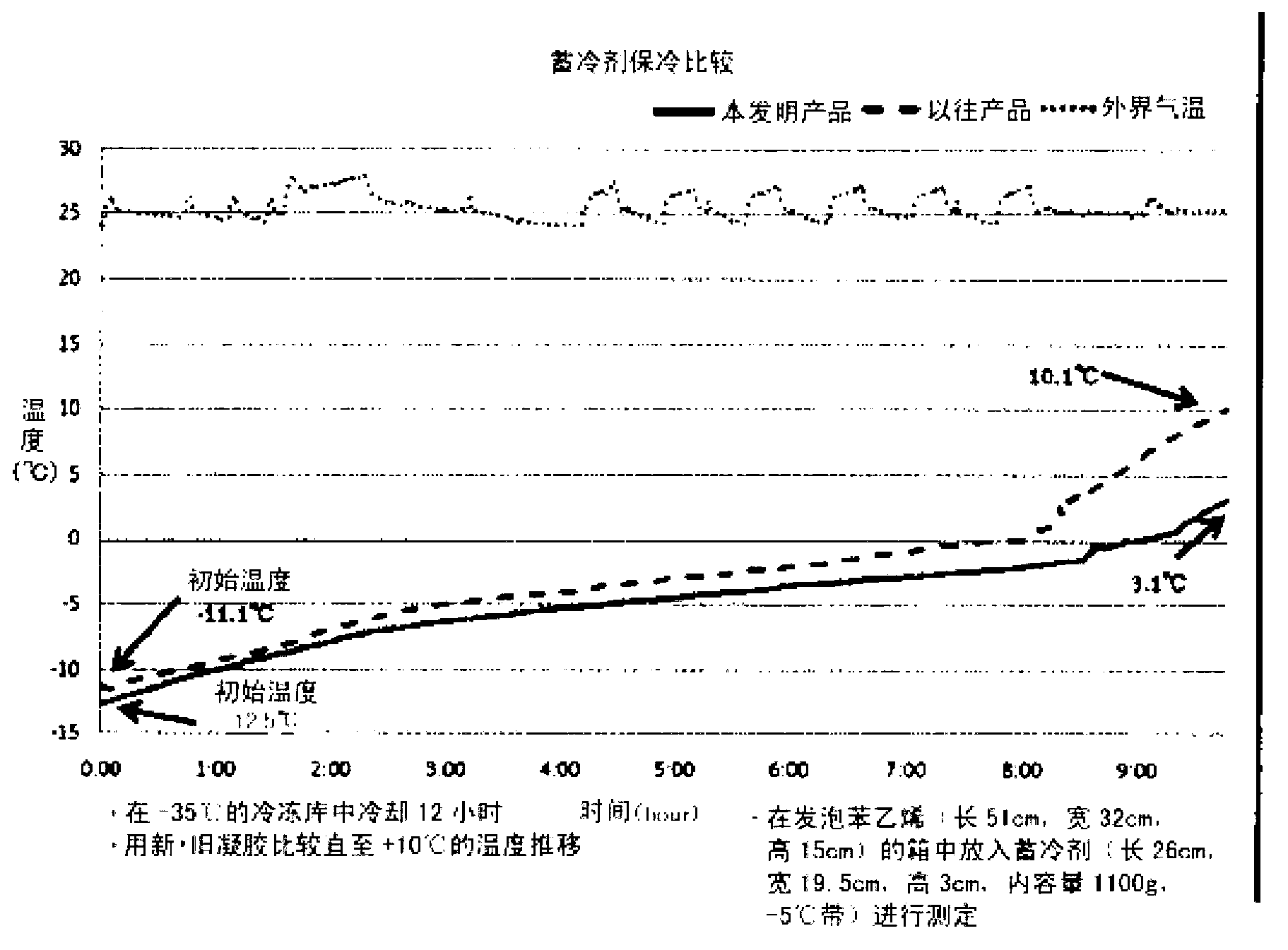

[0045] Put the cooling agent box cooled in the freezer at -35°C for 24 hours in a box made of expanded styrene (width 32cm x length 51cm x height 15cm), and place the box made of expanded styrene at room temperature Next, the temperature insi...

Embodiment 2

[0057] 650 g of the cool storage agent prepared in Production Example 1 was filled in a cool storage agent box (width 15 cm x length 26.5 cm x thickness 2 cm), and the freezing time and cooling time were measured.

[0058]

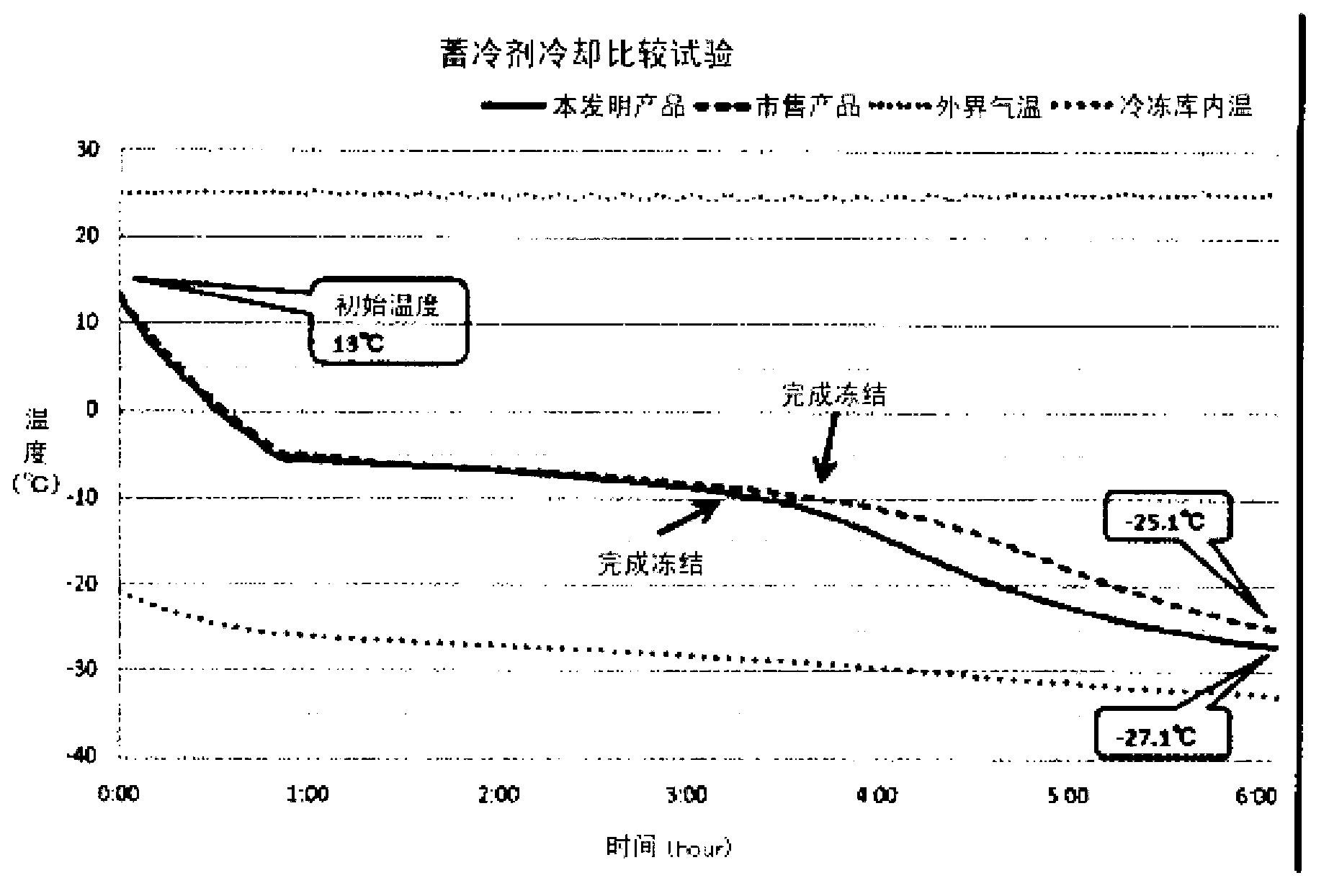

[0059] After the cooling storage box was left at room temperature, it was placed in a fanless freezer at -35°C to cool for 24 hours, and the time required for freezing was measured. The results are shown in image 3 .

[0060] The initial temperature of the cold storage agent is 13°C. About 50 minutes after being placed in the freezer, the temperature of the cold storage agent drops sharply to -5°C, completes freezing in about 3 hours and 10 minutes, and reaches -27.1°C after 6 hours.

[0061]

[0062] Put the cooling agent box cooled in the freezer at -35°C for 24 hours in a box made of expanded styrene (width 32cm x length 51cm x height 15cm), and place the box made of expanded styrene at room temperature Next, the temperature inside the box made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com