Treatment method of continental shale gas well fracturing operation waste liquid

A technology for shale gas wells and treatment methods, which is applied in mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. problems, to achieve the effect of stable treatment effect, good environmental protection and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

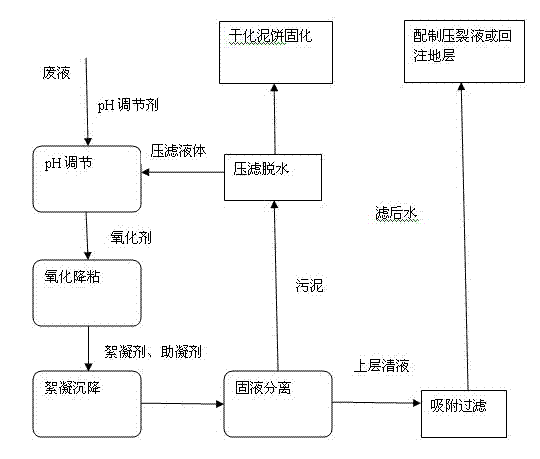

Image

Examples

Embodiment 1

[0017] Take a fracturing waste fluid produced during the development of shale gas vertical wells as an example.

[0018] The pH value of the waste liquid is 9.1, wherein the ferrous content is 21 mg / L, the suspended matter is 490 mg / L, the turbidity is 398 NTU, and the viscosity is 5.3 mPa·S.

[0019] The waste liquid is treated by using the waste liquid treatment method of continental shale gas well fracturing operation. The specific treatment steps are as follows:

[0020] Step 1, pH adjustment; add a pH regulator to the waste liquid, choose hydrochloric acid as the pH regulator, that is, add hydrochloric acid to the waste liquid to adjust the pH value of the waste liquid, so that the pH value of the waste liquid reaches 5.5.

[0021] Since the commonly used oxidants are generally acidic oxidants, adjusting the pH value of the waste liquid to weak acidity is beneficial to the implementation of subsequent steps.

[0022] Step 2, oxidative viscosity reduction; add an oxidant ...

Embodiment 2

[0034] Take a fracturing waste fluid produced during the development of shale gas horizontal wells as an example.

[0035] The pH value of the waste liquid is 6, the ferrous iron content is 36 mg / L, the suspended matter is 540 mg / L, the turbidity is 439 NTU, and the viscosity is 4.6 Pa·S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com