Composite foamed cement insulation board for tile surface and preparation method thereof

A composite foam cement and insulation board technology, applied in the field of insulation board materials, can solve the problems of low tensile strength, inability to be used for tile veneer, high tensile bonding strength, etc., to achieve enhanced safety, high cost performance, The effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

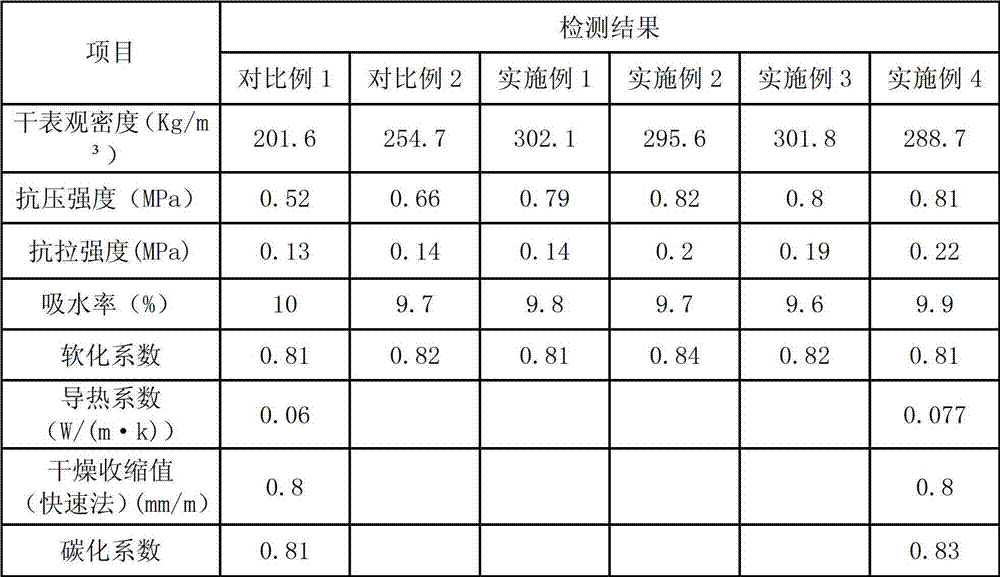

Examples

Embodiment 1

[0059] (1) Raw materials and their ratio

[0060] 425R Portland cement 100kg,

[0061] Fly ash 20kg,

[0062] Water reducer (polycarboxylate) 0.06kg,

[0063] Calcium chloride accelerator 2.0kg,

[0064] Accelerator 0.5kg,

[0065] PP fiber 0.4kg,

[0066] water 60kg,

[0067] Hydrogen peroxide 6.0kg,

[0068]Animal oil foam stabilizer 1.5kg.

[0069] The quick-setting agent is composed of: sodium carbonate: sodium hypochlorite: calcium sulfate compounded according to the ratio of 1:1:2.

[0070] (2) Preparation method

[0071] Preparation of quick-setting agent: Mix sodium carbonate, sodium hypochlorite, and calcium sulfate completely in a ratio of 1:1:2.

[0072] According to the above weight, put 425R Portland cement, fly ash, water, PP fiber, calcium chloride early strength agent, accelerator and water reducer (polycarboxylate) into the stirring tank and stir, beating for 5 minutes, and then Add hydrogen peroxide and animal oil foam stabilizer, stir for 10 second...

Embodiment 2

[0075] (1) Raw materials and their ratio

[0076] 425R Portland cement 100kg,

[0077] Fly ash 20kg,

[0078] Water reducing agent (naphthalene series) 0.5kg,

[0079] Calcium chloride accelerator 2.0kg,

[0080] accelerator 0.5,

[0081] PP fiber 0.4kg,

[0082] water 60kg,

[0083] Hydrogen peroxide 6.0kg,

[0084] Animal oil foam stabilizer 1.5kg;

[0085] The quick-setting agent is composed of: sodium carbonate: sodium hypochlorite: calcium sulfate compounded according to the ratio of 1:1:2.

[0086] (2) Preparation method

[0087] Preparation of quick-setting agent: Mix sodium carbonate, sodium hypochlorite, and calcium sulfate completely in a ratio of 1:1:2.

[0088] According to the above weight, put 425R Portland cement, fly ash, water, PP fiber, calcium chloride early strength agent, accelerator and water reducer (naphthalene series) into the stirring tank, stir for 5 minutes, and then add hydrogen peroxide and animal oil foam stabilizer, stirred for 10 seco...

Embodiment 3

[0091] (1) Raw materials and their ratio

[0092] 525R Ordinary Portland Cement 100kg,

[0093] Fly ash 20kg,

[0094] Water reducing agent (naphthalene series) 0.5kg,

[0095] Calcium chloride accelerator 1.0kg,

[0096] Accelerator 1.0kg,

[0097] PP fiber 0.4kg,

[0098] water 60kg,

[0099] Hydrogen peroxide 6.0kg,

[0100] Animal oil foam stabilizer 1.5kg;

[0101] The quick-setting agent is composed of: sodium carbonate: sodium hypochlorite: calcium sulfate compounded according to the ratio of 1:1:2.

[0102] (2) Preparation method

[0103] Preparation of quick-setting agent: Mix sodium carbonate, sodium hypochlorite and calcium sulfate completely and evenly in a ratio of 1:1:2.

[0104] According to the above weight, put 525R Portland cement, fly ash, water, PP fiber, calcium chloride early strength agent, accelerator and water reducer (naphthalene series) into the stirring tank, stir for 5 minutes, and then add hydrogen peroxide and animal oil foam stabilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com