Preparation method of amlodipine maleate

A kind of technology of amlodipine maleate and amlodipine, applied in the field of preparation of amlodipine maleate, can solve the problems of complicated operation and high content of related substances, achieve simple operation, reduce the content of related substances, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of amlodipine maleate, comprising the following steps:

[0029] a) react maleic acid and amlodipine free base in water to obtain amlodipine crude product;

[0030] b) refining the crude amlodipine maleate obtained in step a) to obtain amlodipine maleate.

[0031] The present invention uses maleic acid and amlodipine free base as raw materials and water as a reaction medium to prepare amlodipine maleate. The operation is not only simple, but also the content of related substances in the prepared amlodipine maleate is extremely low.

[0032] The present invention uses maleic acid as a raw material, and the maleic acid is also called maleic acid. The present invention has no special limitation on its source, and commercially available products are sufficient.

[0033] The present invention uses amlodipine free base as raw material, and described amlodipine free base is also called amlodipine base, and its molecular formu...

Embodiment 1

[0051] Disperse 1mol of maleic acid and 1.1mol of amlodipine free base in 2.2L of water, stir and react at 10°C for 2h, filter the resulting reaction mixture to obtain the crude product of amlodipine maleate; Dipine crude product is dispersed in ethanol, the ratio of the volume of described ethanol and the quality of described amlodipine maleate crude product is 14L: 1kg, add 0.03g medicinal charcoal after heating to reflux, reflux 30min, drop to room temperature, in- Place crystallization at 5°C for 4h, centrifuge, and then dry at 25°C and >0.08MPa to obtain amlodipine maleate with a yield of 65%.

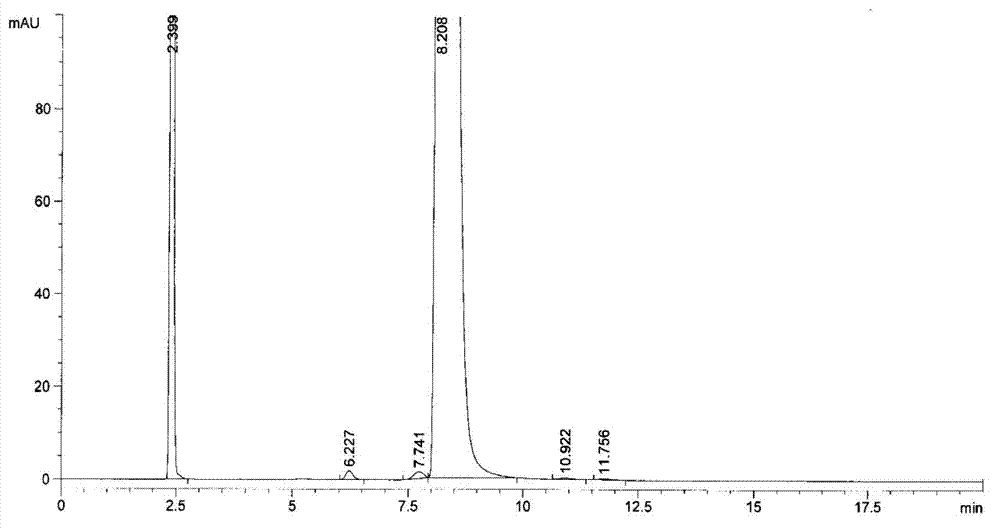

[0052] Described amlodipine maleate is carried out high performance liquid chromatography analysis, the result sees figure 1 , figure 1 For the high performance liquid chromatogram of the amlodipine maleate prepared by Example 1 of the present invention, by figure 1 It can be seen that the present invention has prepared amlodipine maleate with a purity of 99.7%, a single maximum...

Embodiment 2

[0054] Disperse 2mol of maleic acid and 2.2mol of amlodipine free base in 4.4L of water, stir and react at 15°C for 1h, filter the resulting reaction mixture to obtain the crude product of amlodipine maleate; The dipine crude product is dispersed in ethanol, the ratio of the volume of the ethanol to the mass of the amlodipine maleate crude product is 14L: 1kg, after stirring at -5°C for 4h, suction filtration under reduced pressure, and then at 23°C, > Dry under the condition of 0.08MPa, obtain amlodipine maleate, and yield is 60%.

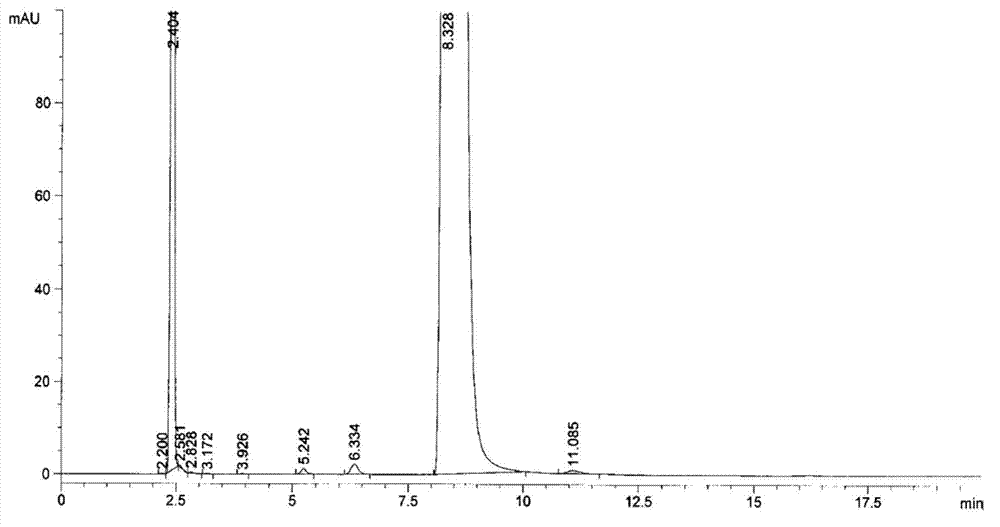

[0055] Described amlodipine maleate is carried out high performance liquid chromatography analysis, the result sees figure 2 , figure 2 For the high performance liquid chromatogram of the amlodipine maleate prepared by the embodiment of the present invention 2, by figure 2 It can be seen that the present invention has prepared amlodipine maleate with a purity of 99.8%, a single largest impurity of 0.11%, and a total impurity of 0.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com