Heat resisting rubber tube

A technology of heat-resistant rubber and butyl rubber, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve problems such as loss of function, waste of heat-resistant rubber tubes, poor heat resistance, etc., to achieve extended product The effect of life and heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific component content of the heat-resistant rubber tube of the present embodiment is calculated by weight percentage:

[0024] Butyl rubber: 80 grams; sulfur 1 gram; accelerator M 0.3 grams; accelerator TT 0.8 grams; zinc oxide 3 grams; magnesium oxide 3 grams; stearic acid 0.8 grams; paraffin wax 2 grams; heat-resistant aging agent D 1 gram ; 50 grams of aluminum silicate; 40 grams of calcium carbonate; 1 gram of anti-aging agent MB.

[0025] The production method of this heat-resistant rubber tube comprises and steps:

[0026] (a) Add 80 grams of butyl rubber to the rubber mixing machine. After mixing for 2 minutes, add 1 gram of sulfur, 3 grams of zinc oxide, 3 grams of magnesium oxide, 0.8 grams of stearic acid, 2 gram of paraffin pounded evenly;

[0027] (b) Then adjust the roll distance to 5mm, add 0.3g of accelerator M, 0.8g of accelerator TT, 1g of heat-resistant aging agent D, 50g of aluminum silicate, 1g of antioxidant MB, and 40g of calcium carbona...

Embodiment 2

[0034] The production process of this embodiment is basically the same as that of Example 1, except that the component ratio of the heat-resistant rubber tube is different. The specific component content of the heat-resistant rubber tube in Example 2 is calculated in weight percent:

[0035] 100 grams of butyl rubber; 1.5 grams of sulfur; 0.4 grams of accelerator M; 1 gram of accelerator TT; 4 grams of zinc oxide; 4 grams of magnesium oxide; 1 gram of stearic acid; 3 grams of paraffin; 65 grams of aluminum acid; 50 grams of calcium carbonate; 2 grams of anti-aging agent MB.

Embodiment 3

[0037] The production process of this embodiment is basically the same as that of Example 1, except that the component ratios of the heat-resistant rubber tube are different. The specific component content of the heat-resistant rubber tube in Example 3 is calculated in weight percent:

[0038] Butyl rubber: 120 grams; 2 grams of sulfur; 0.5 grams of accelerator M; 1.2 grams of accelerator TT; 5 grams of zinc oxide; 5 grams of magnesium oxide; 1.2 grams of stearic acid; 4 grams of paraffin; heat-resistant aging agent D 1.3 grams; 80 grams of aluminum silicate; 60 grams of calcium carbonate; 3 grams of antioxidant MB.

[0039] The unit of each component is not limited to the grams in the examples, as long as the ratios are consistent with each other, units such as kilograms, kilograms, and catties can be used.

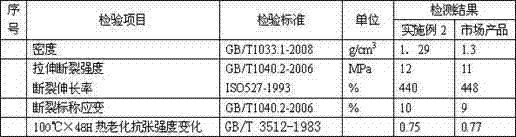

[0040] Performance comparison of three kinds of embodiment schemes:

[0041]

[0042] The scheme described in embodiment 2 is compared with current market product: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com