Flue corrosion prevention compensator

A technology of compensator and flue, which is applied in pipeline anti-corrosion/rust protection, expansion compensation device for pipelines, damage protection, etc. It can solve the problem of low connection strength at metal joint sockets and delamination of rubber pipe sleeves Low structural strength, short service life of the flue compensator, etc., to achieve the effects of flexible compensation or absorption action, enhanced deformation ability, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

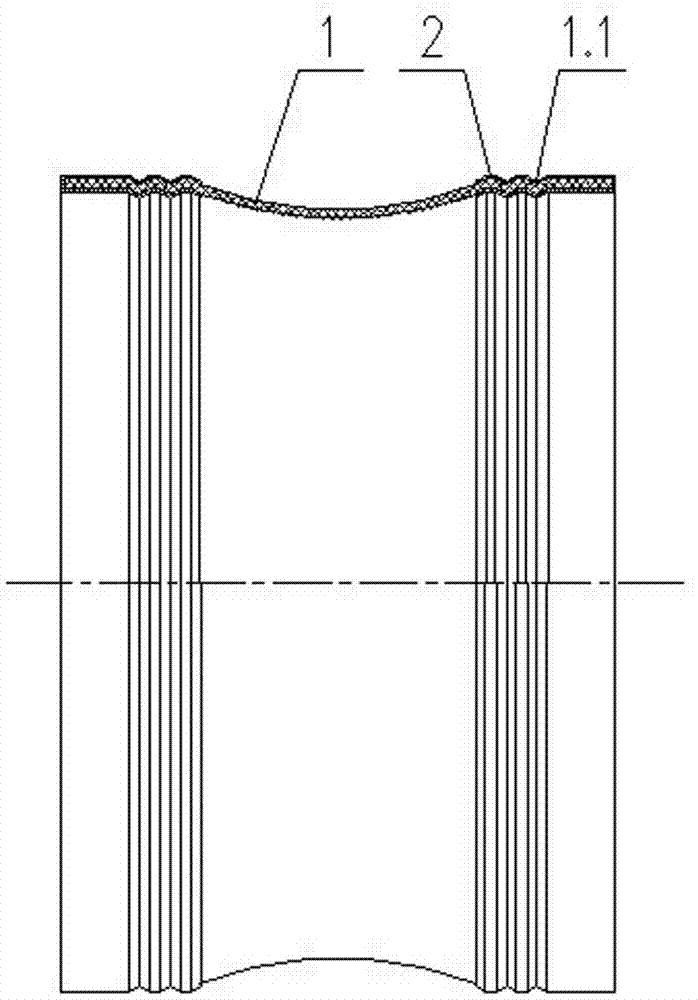

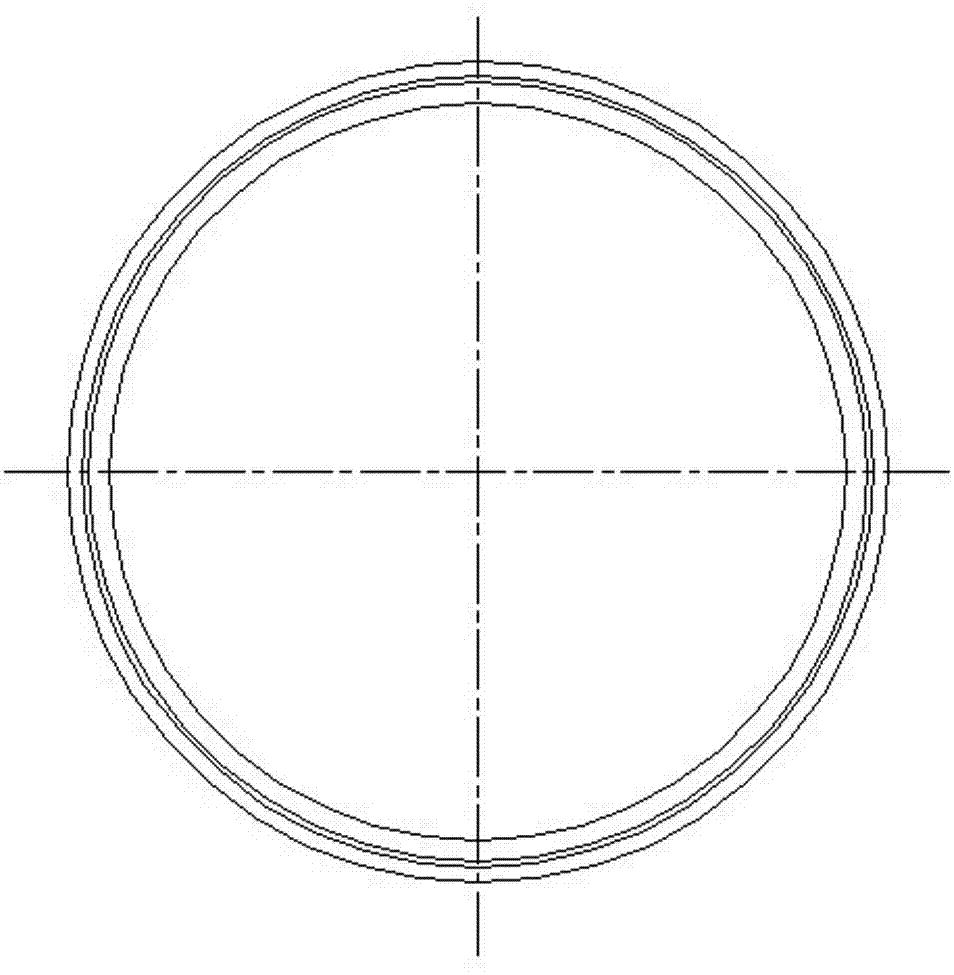

[0015] figure 1 The shown flue anti-corrosion compensator includes hose 1 and connecting pipe 2. The hose 1 is a single-layer thick-walled rubber product, the middle section of the axial section is waist-shaped, and the left and right pipe ends are round and straight pipes. The connecting pipe 2 is a round straight pipe with a jacket structure, and the axial section on one side is a rectangular groove in a lying position, and the opening width of the groove is equal to the wall thickness at both ends of the hose 1 . In this embodiment, due to the small diameter of the supporting flue, the wall thickness of the hose 1 is 5mm, and the whole hose 1 is vulcanized. In order to improve the anti-corrosion performance, the connecting pipe 2 is made of nickel-based alloy steel with good anti-corrosion performance, and the inner surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com