Air floatation vibration isolation platform on basis of air floatation zero-position reference and laser auto-collimation measurement

A vibration isolation platform and zero reference technology, which is applied in the direction of machine/support, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problem of no absolute zero reference, slow system response speed, difficult high-precision measurement, etc. problems, to achieve the effect of improving stability and improving vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

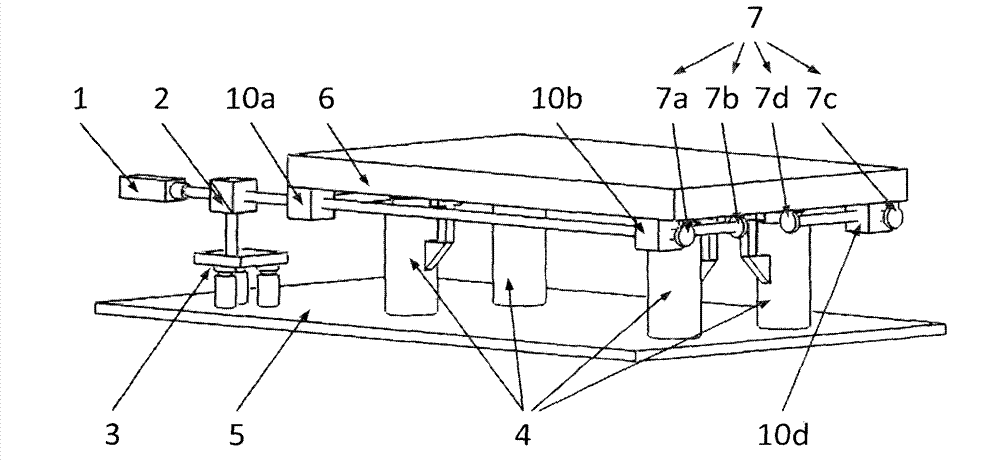

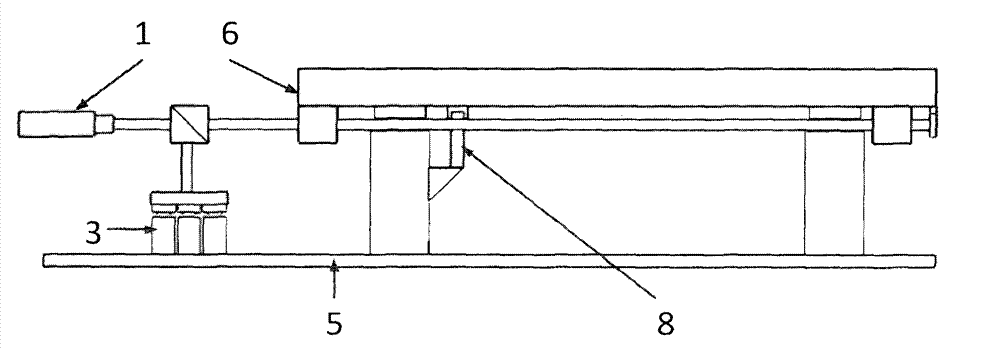

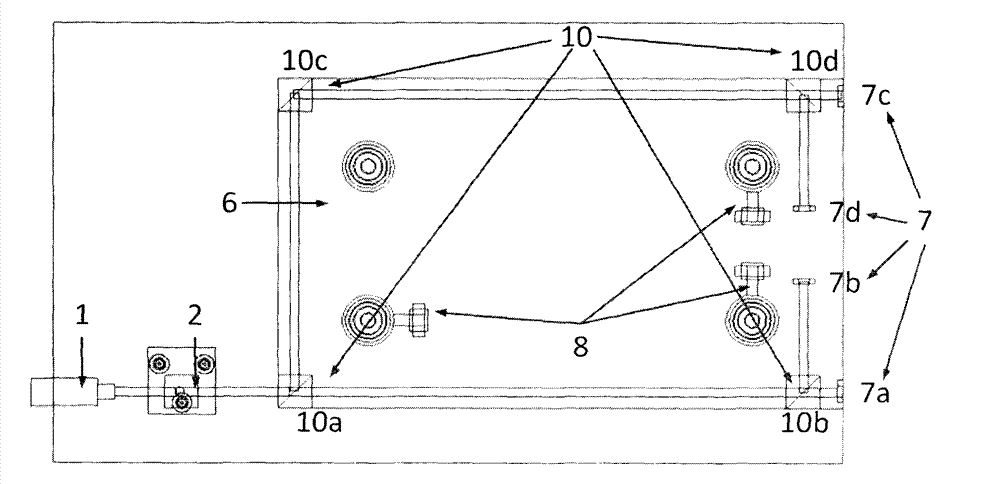

[0029] Below in conjunction with accompanying drawing, embodiment of the present invention is described in further detail:

[0030] An air-floating vibration-isolation platform based on air-floating zero reference and laser self-collimation measurement, the air-floating vibration-isolation platform body 6 is arranged on three or more evenly distributed vibration isolators 4, and the vibration isolators 4 is arranged on the base 5, and the vibration isolator 4 is composed of a vibration isolator base 4a, a vibration isolator bracket 4b and a vibration isolator table 4c, and the vibration isolator table 4c is installed on the vibration isolator base 4a Inside, the vibration isolator support 4b is arranged on the outer side of the vibration isolator base 4a, and the horizontal displacement actuator 8 is arranged between each vibration isolator 4 and the air-floating vibration isolation platform body 6, and the horizontal displacement actuator 8 adopts a horizontally placed linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com