Micro cone tower array heat exchanging plate and manufacture method thereof

A manufacturing method and heat exchange plate technology, applied in heat exchange equipment, lighting and heating equipment, electrical components, etc., can solve the complex shape, single internal shape of flow channel, heat transfer performance limitation of microchannel heat exchange plate, etc. problems, to achieve the effect of wide application fields, low equipment cost investment, and rich shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

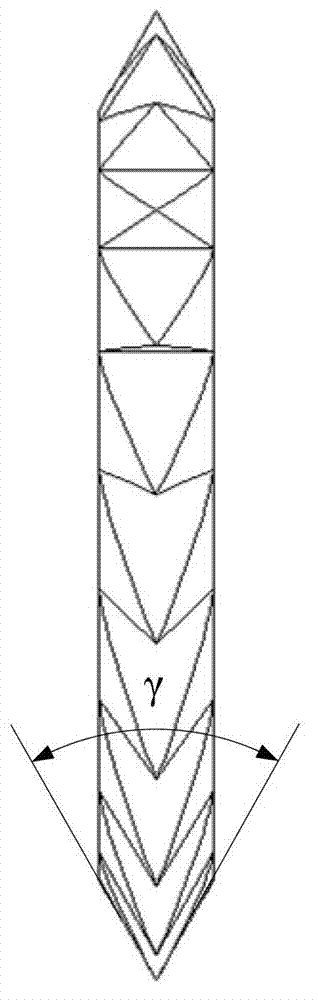

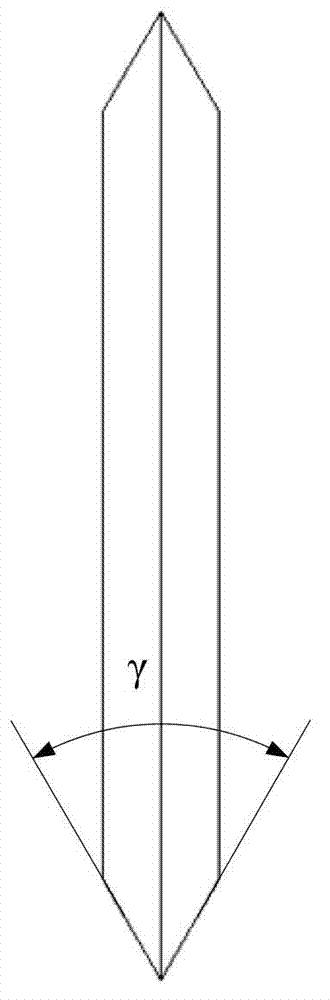

Embodiment 1

[0050] Such as Figure 3 to Figure 5 As shown, taking a thin plate with a milling thickness of 0.17mm as an example, the number of directions of the "V" groove array on each surface of the thin plate is n 1 =3, the "V"-shaped grooves of the same array are parallel to each other, the "V"-shaped grooves of different arrays have an angle between each other, and the angle between two adjacent "V"-shaped groove arrays is θ=60°, "V" The angle between the two sides of the groove is 60° (that is, the slope of the "V" groove is 60°), the depth of the "V" groove is 0.087mm, and the distance between the two "V" grooves in the same array is 0.1mm. The angle between the two first direction arrays is α=90°, the offset of one direction array relative to the intersection point of the other two direction arrays is b=0.05mm, the substrate is a copper plate, and finally forms a regular triangular pyramid with two heights A heat exchange plate with a micro-pyramid tower array structure mixed wit...

Embodiment 2

[0057] Such as Figure 6 to Figure 8 As shown, taking the thin plate with a grinding thickness of 0.22mm as an example, the number of directions of the "V" groove array on each surface of the thin plate is n 1 =3, the "V"-shaped grooves of the same array are parallel to each other, the "V"-shaped grooves of different arrays have an angle between each other, and the angle between two adjacent "V"-shaped groove arrays is θ=60°, "V" The angle between the two sides of the groove is 90° (that is, the slope of the "V" groove is 45°), the depth of the "V" groove is 0.1mm, and the distance between the two "V" grooves in the same array is 0.2mm. The included angle of the array in the first direction is β=0°, the offset of the array in one direction relative to the intersection point of the array in the other two directions is c=0.05mm, and the substrate is an aluminum plate, finally forming a regular triangular pyramid with three heights and the like A heat exchange plate with a micro...

Embodiment 3

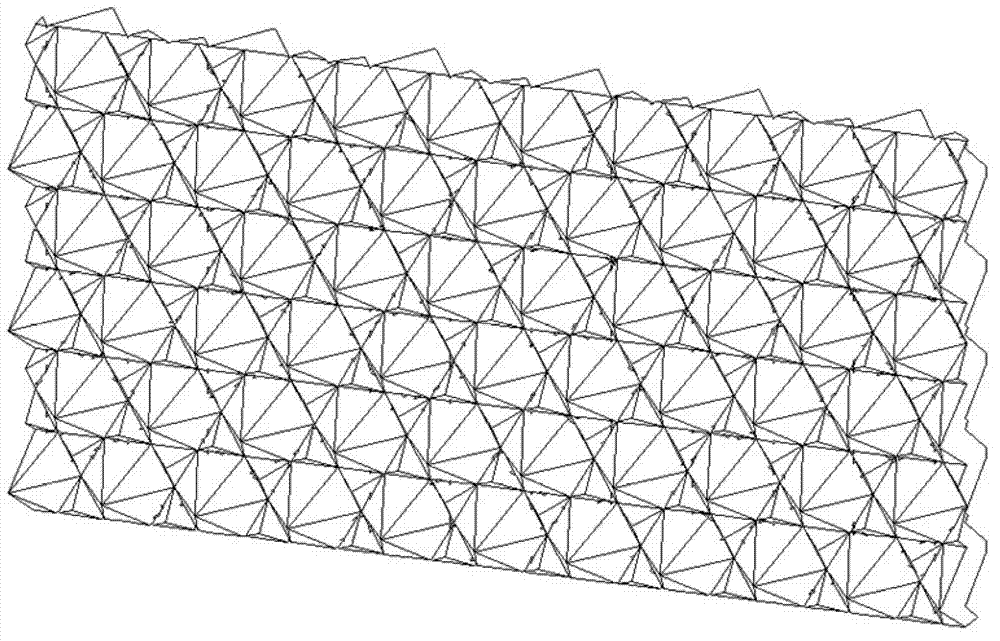

[0064] Such as Figure 9 to Figure 11 As shown, taking a thin plate with a milling thickness of 0.38mm as an example, the number of directions of the "V" groove array on each surface of the thin plate is n 1 =5, the "V" grooves of the same array are parallel to each other, the "V" grooves of different arrays have an angle between each other, and the angle between two adjacent "V" groove arrays is θ=36°, "V" The angle between the two sides of the groove is 90° (that is, the slope of the "V" groove is 45°), the depth of the "V" groove is 0.1mm, and the distance between the two "V" grooves in the same array is 0.2mm. The included angle between the first direction arrays is β=0°, the offsets of the five direction arrays relative to the center of the thin plate are all d=0.1mm, and the substrate is a copper plate, finally forming a pyramid with different heights and The utility model relates to a heat exchange plate with a microcone tower array structure mixed with cone-like circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com