Array type wide-temperature laser module

A laser module and array technology is applied in the field of laser applications to improve the spot quality and power stability, solve the problem of disconnection, and improve the quality of the output spot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

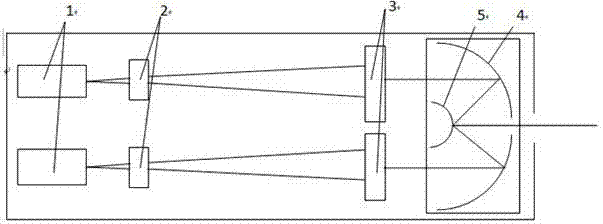

Embodiment 1

[0025] This embodiment includes a laser module array. The laser module array includes at least two laser modules 1 with different temperature bandwidths. The laser beam emitted by the laser module array is shaped by a beam shaping system and an afocal optical system to form a beam Combined beam. The afocal optical system is composed of two parabolic mirrors, one large and one small. The larger one is a concave parabolic mirror 4 with a circular hole in the center to transmit light. The diameter of the circular hole is slightly larger than the diameter of the output light; the smaller one is convex parabolic. Mirror 5, the two parabolic mirrors are confocal. The beam shaping system is arranged in front of or behind the afocal optical system. The beam shaping system is set as a Galileo telescope lens group. The beam shaping system is set as a lens group consisting of a self-focusing lens and a spherical mirror. The laser modules in the laser module array are evenly arranged al...

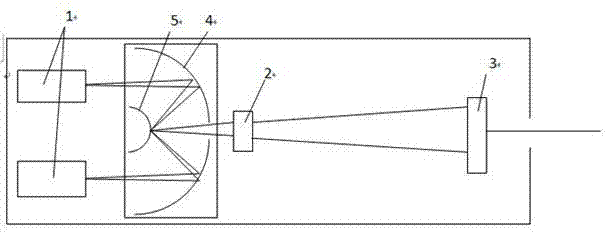

Embodiment 2

[0028] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the light from the laser module array of this embodiment first passes through the afocal optical system to form a combined beam, and then passes through the beam expander lens 2 and the collimator lens 3 for shaping and output.

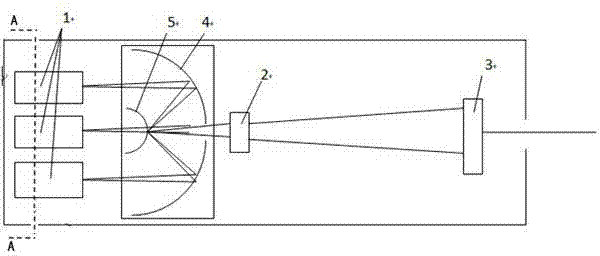

Embodiment 3

[0030] Such as image 3 , 4 As shown, the difference between this embodiment and Embodiment 2 is that the laser module array of this embodiment is provided with four laser modules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com