Oyster powder, oyster fine powder and preparation method

A technology for oyster powder and oyster meat is applied in the field of condiments to achieve the effects of rich nutrition, convenient use and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Formula of Oyster Extract Powder

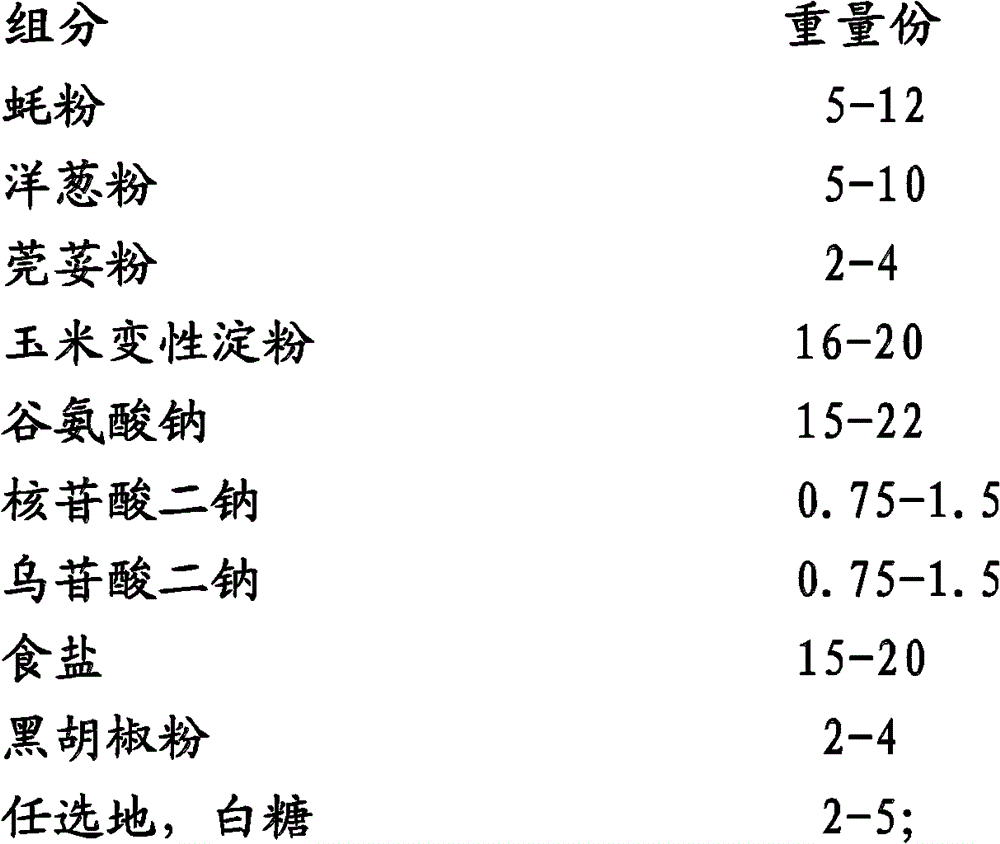

[0035] In parts by weight, the components of oyster extract powder are:

[0036]

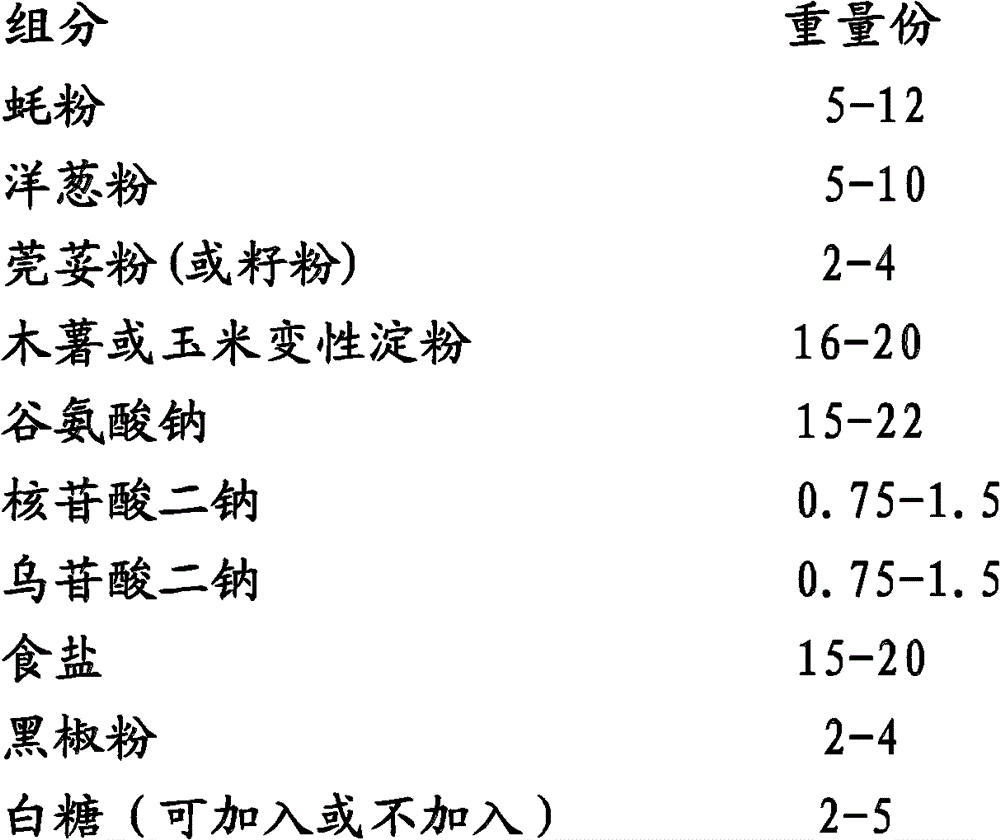

[0037] For example, the specific formula of oyster extract powder is:

[0038]

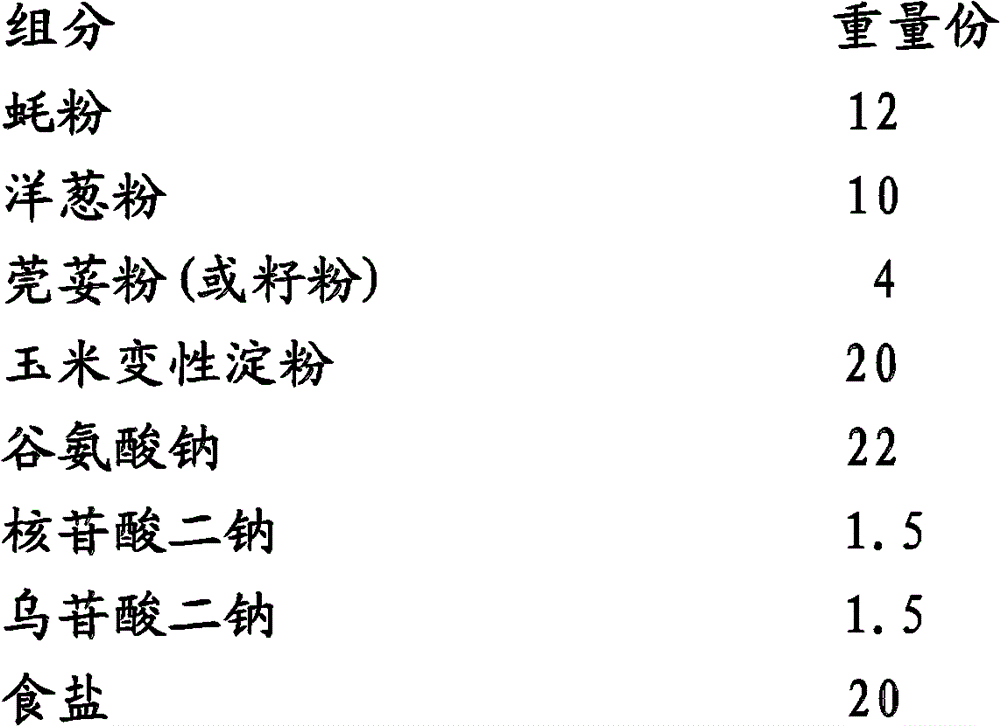

[0039]

[0040] Or, the specific formula of oyster extract powder is:

[0041]

Embodiment 2

[0042] Example 2 Preparation of Oyster Extract Powder

[0043] 1. Preparation of each component in oyster extract powder

[0044] (1) Oyster noodles: Pick up fresh oysters from the sea, remove their shells manually, blanch them for freshness, and boil for half an hour to denature the protein, and enter the hot air dryer at 60-70°C for air drying for 4-6 hours; after the oysters are air dried Then enter the screw machine (TSE65 twin-screw extruder, Beijing Hyundai Yanggong Machinery Development Co., Ltd.), high temperature and high pressure, the condition is 220-250 ℃, 30 minutes, to obtain coarse powder, then crush and sieve to make it into Powder.

[0045] (2) Black pepper powder: use immature pepper seeds (pick off white pepper when mature), air-dry, turn black, and then grind;

[0046] (3) Onion powder: use Northwest red / yellow onions, dehydrated and dried, and ground into powder.

[0047] (4) Coriander powder (or seed powder): Mature coriander seeds are dried in hot air and ground...

Embodiment 3

[0051] Example 3 Use of Oyster Extract Powder

[0052] (1) Can replace MSG or chicken essence as seasoning

[0053] (2) Take an appropriate amount of oyster extract powder, such as 20-30g, and brew it with 15-20 times (weight ratio) of boiling water to make a seafood-flavored oyster soup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com