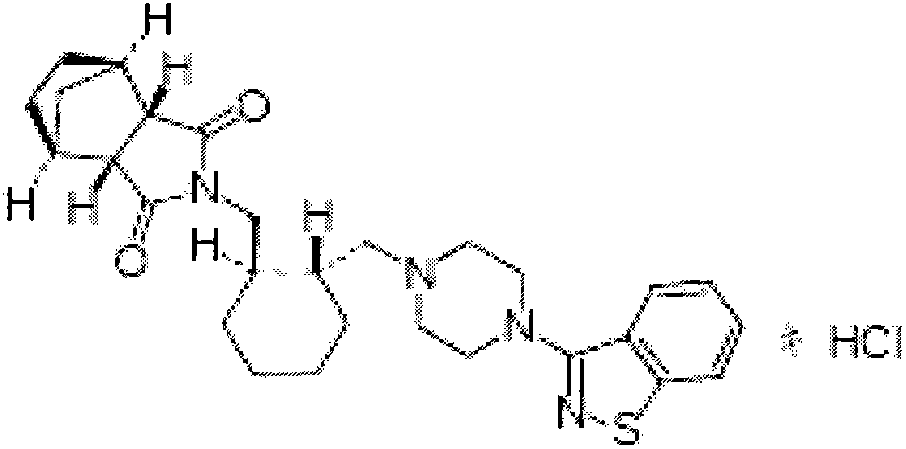

Lurasidone hydrochloride orally-disintegrating tablet preparation and preparation method thereof

A technique for lurasidone hydrochloride orally disintegrating tablets and lurasidone hydrochloride, applied in the field of pharmaceutical preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

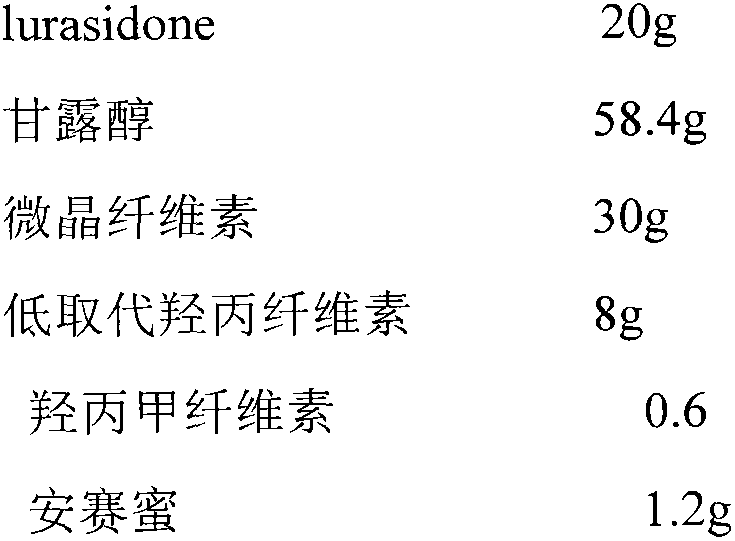

[0029] Specific Example 1 Lurasidone Hydrochloride Orally Disintegrating Tablets (1000 Tablets)

[0030]

[0031]

[0032] Preparation method:

[0033] 1. Pass the raw and auxiliary materials through a 100-mesh sieve.

[0034] 2. Mix the prescribed amount of lurasidone with mannitol, microcrystalline cellulose, and low-substituted hydroxypropyl cellulose in a mixer.

[0035] 3. Add 60% alcohol solution of 2% hypromellose to the above mixture to make soft material and granulate.

[0036] 4. Dry until moisture L.O.D (90°C, 5min) < 3%, granulate, add the dosage of low-substituted hydroxypropyl cellulose, acesulfame potassium, mint flavor and magnesium stearate, and mix with the above-mentioned granules with medicine.

[0037] 5. Measure the particle content, calculate the weight of the tablet, and press the tablet to make a total of 1000 tablets, and control the hardness to 20-40N.

specific Embodiment 2

[0038] Specific Example 2 Lurasidone Hydrochloride Orally Disintegrating Tablets (1000 Tablets)

[0039]

[0040] Preparation method:

[0041] 1. Pass the raw and auxiliary materials through a 100-mesh sieve.

[0042] 2. Mix the prescribed amount of lurasidone with lactose, microcrystalline cellulose, and croscarmellose sodium in a mixer.

[0043] 3. Add 60% hypromellose solution to the above mixture to make soft material and granulate.

[0044] 4. Dry until moisture L.O.D (90°C, 5min) < 3%, granulate, convert the amount of croscarmellose sodium, acesulfame potassium, mint essence and magnesium stearate, and mix with the above-mentioned granules with medicine uniform.

[0045] 5. Measure the particle content, calculate the weight of the tablet, and press the tablet to make a total of 1000 tablets, and control the hardness to 20-40N.

specific Embodiment 3

[0046] Specific Example 3 Lurasidone Hydrochloride Orally Disintegrating Tablets (1000 Tablets)

[0047]

[0048] Preparation method:

[0049] 1. Pass the raw and auxiliary materials through a 100-mesh sieve.

[0050] 2. Mix the prescribed amount of lurasidone with lactose, microcrystalline cellulose, and cross-linked polyvinylpyrrolidone in a mixer.

[0051] 3. Add 40% alcohol aqueous solution to the above mixture to make soft material and granulate.

[0052] 4. Dry until moisture L.O.D (90°C, 5min) < 3%, granulate, convert the amount of cross-linked polyvinylpyrrolidone, acesulfame potassium, mint flavor and magnesium stearate, and mix with the above-mentioned granules with medicine.

[0053] 5. Measure the particle content, calculate the weight of the tablet, and press the tablet to make a total of 1000 tablets, and control the hardness to 20-40N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com