High-manganese aluminum bronze automatic submerged arc welding surfacing method

A submerged arc automatic welding, high manganese aluminum bronze technology, applied in arc welding equipment, welding medium, welding equipment and other directions, can solve the problems of slag inclusion, unfusion and cracking in the welding seam, so as to reduce the cost of the enterprise and improve the welding quality , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Calculate the components according to the ratio of the present invention. The composition of the welding wire is (Wt%): Mn11%, AL7.5%, Fe2%, Ni1%, Si1%, and the balance is Cu. The chemical composition of the flux is (Wt%): CaF 2 40%,MnO6%,TiO 2 7%, CaCl 2 22%, CaO12%, MgO8%, SiO 2 5%.

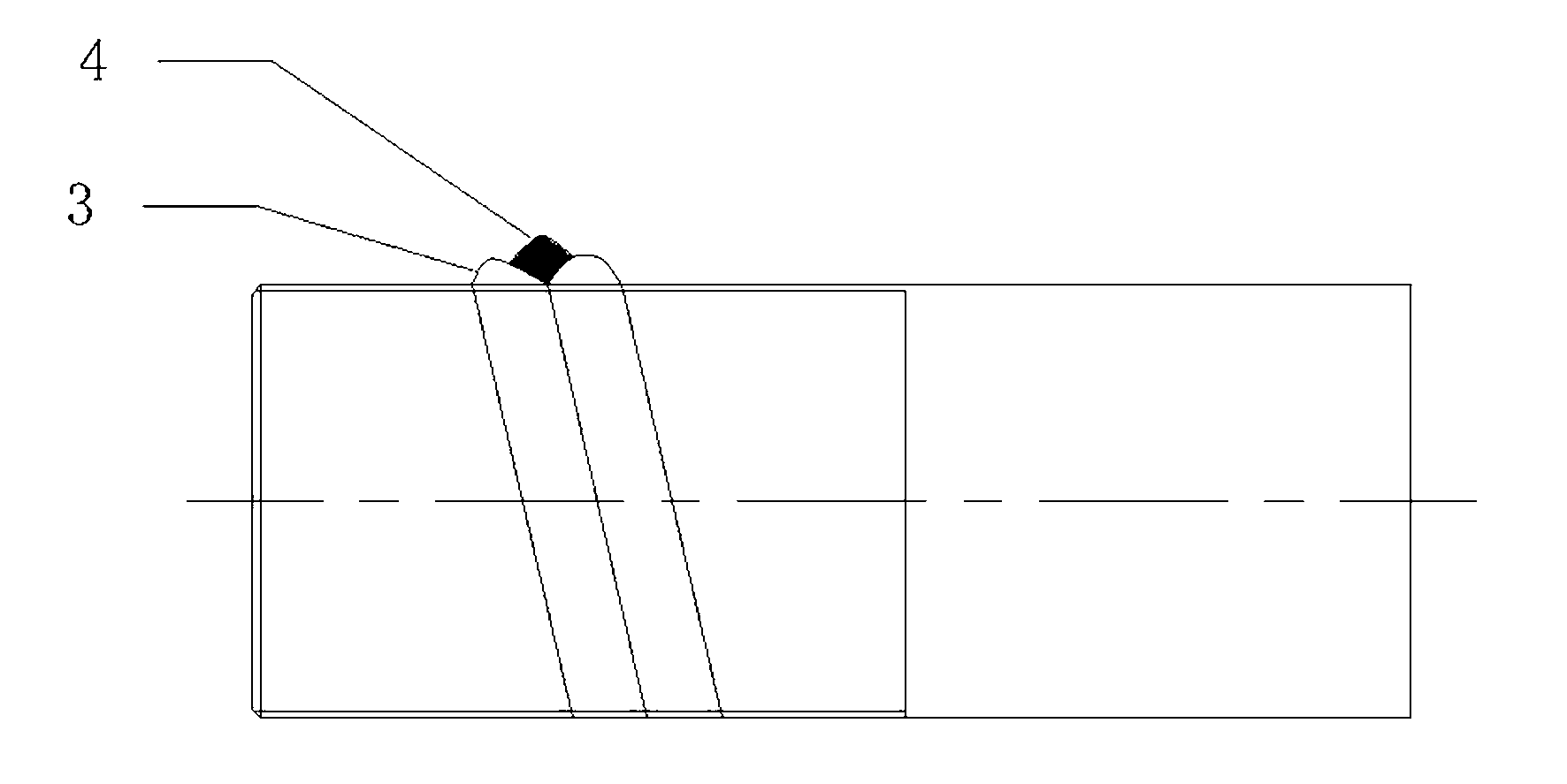

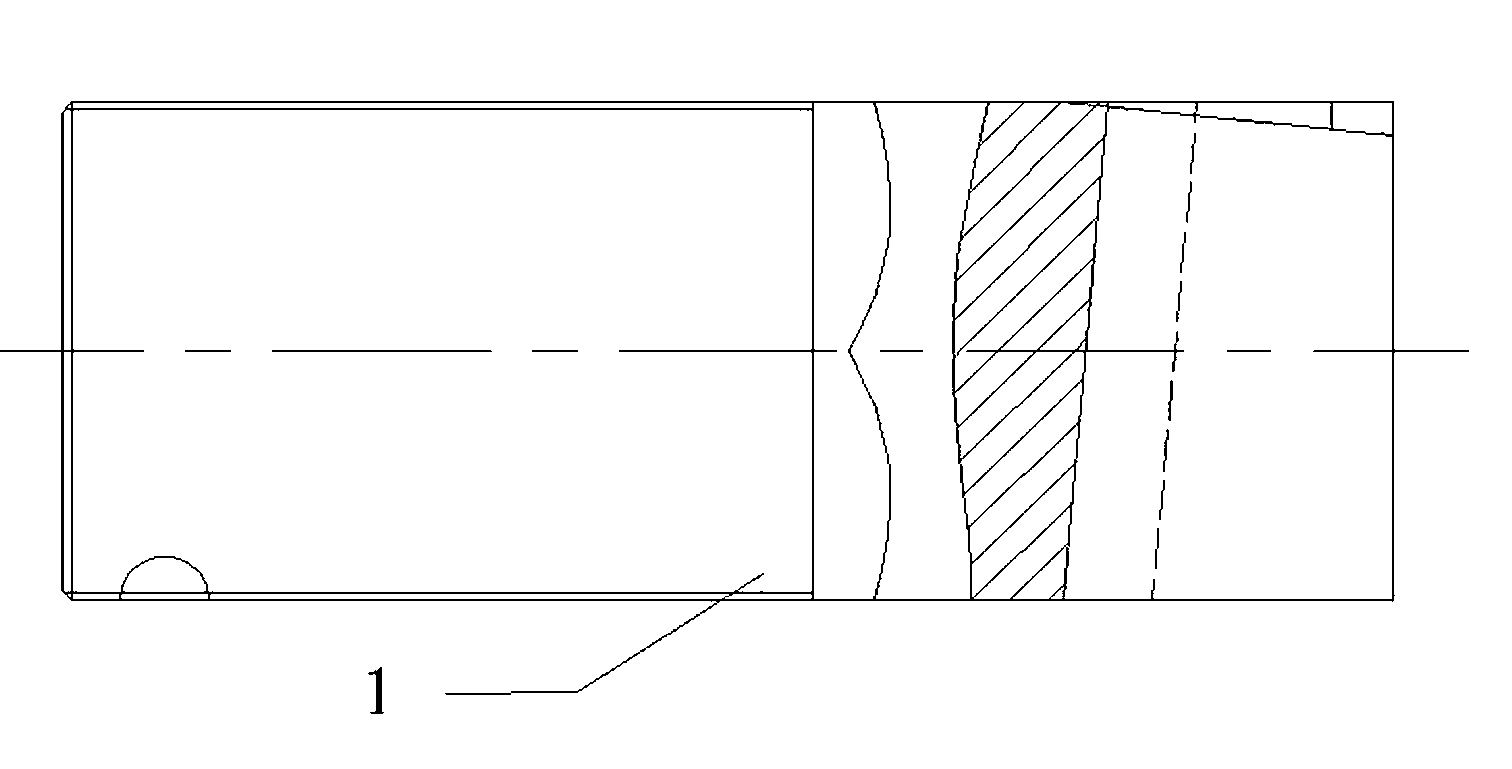

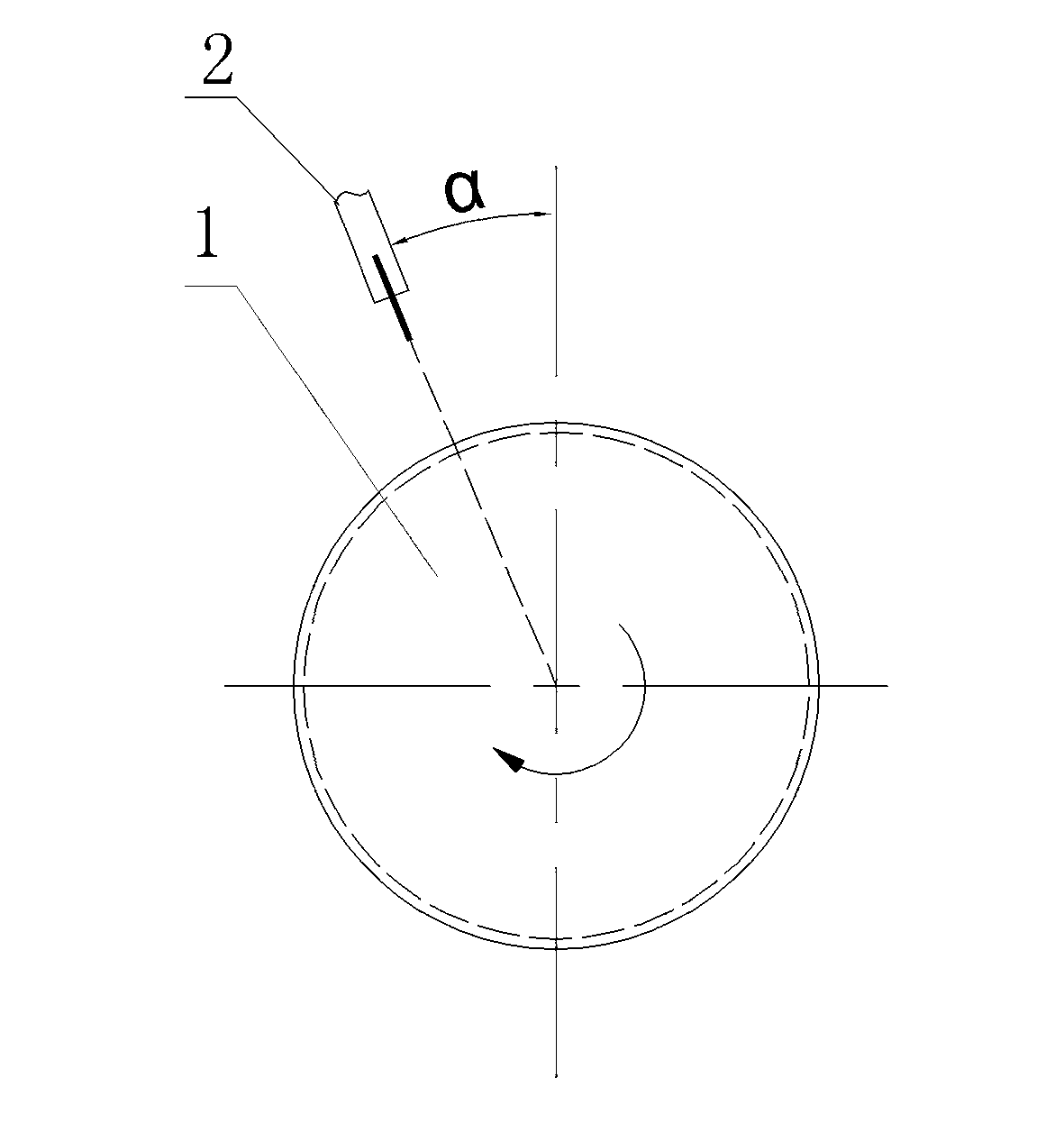

[0018] see figure 1 , 2 , 3. The high manganese aluminum bronze submerged arc automatic welding surfacing method has the following steps: A. Preparation before welding: use the welding wire with the above composition, the diameter is φ1.6mm, and the flux is the flux with the above composition. Preheat the base metal 1 before surfacing, and the base metal 1 is domestic Q460E low-alloy high-strength structural steel. The preheating temperature is 300°C; the welding wire and flux should be dried at 250°C; the flux should be kept at 100°C for 30 minutes for later use. The moisture, grease, impurities and metal oxide film on the surfacing welding surface of the base metal 1...

Embodiment 2

[0022] Example 2: Calculate the components according to the ratio of the present invention. The composition of the welding wire is (Wt%): Mn12%, AL7%, Fe5%, Ni2.1%, Si1%, and the balance is Cu. The chemical composition of the flux is (Wt%): CaF 2 35%,MnO 5%,TiO 2 6%, CaCl 2 25%, CaO13%, MgO9%, SiO 2 7%.

[0023] see figure 1 , 2 , 3. The high manganese aluminum bronze submerged arc automatic welding surfacing method has the following steps: A. Preparation before welding: use the welding wire with the above composition, the diameter is φ1.6mm, and the flux is the flux with the above composition. Preheat the base metal 1 before surfacing, and the base metal is domestic Q460E low-alloy high-strength structural steel. The preheating temperature is 275°C; the welding wire and flux should be dried at 225°C; the flux should be kept at 100°C for 30 minutes for later use. The moisture, grease, impurities and metal oxide film on the surfacing welding surface of the base metal 1 ...

Embodiment 3

[0028] Example 3: Calculate the components according to the ratio of the present invention. The composition of the welding wire is (Wt%): Mn13%, AL5%, Fe6%, Ni2.5%, Si1%, and the balance is Cu. The chemical composition of the flux is (Wt%): CaF 2 30%,MnO8%,TiO 2 4%, CaCl 2 26%, CaO15%, MgO10%, SiO 2 7%.

[0029] see figure 1 , 2 , 3. The high manganese aluminum bronze submerged arc automatic welding surfacing method has the following steps: A. Preparation before welding: use the welding wire with the above composition, the diameter is φ1.6mm, and the flux is the flux with the above composition. Preheat the base metal 1 before surfacing, and the base metal is domestic Q460E low-alloy high-strength structural steel. The preheating temperature is 250°C; the welding wire and flux should be dried at 200°C; the flux should be kept at 100°C for 30 minutes for later use. The moisture, grease, impurities and metal oxide film on the surfacing welding surface of the base metal 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com