Method for preparing graphene efficiently

A graphene and high-efficiency technology, applied in the field of graphene, can solve the problems of low efficiency, pollute the environment, and high cost, and achieve the effects of wide sources, low environmental pollution, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

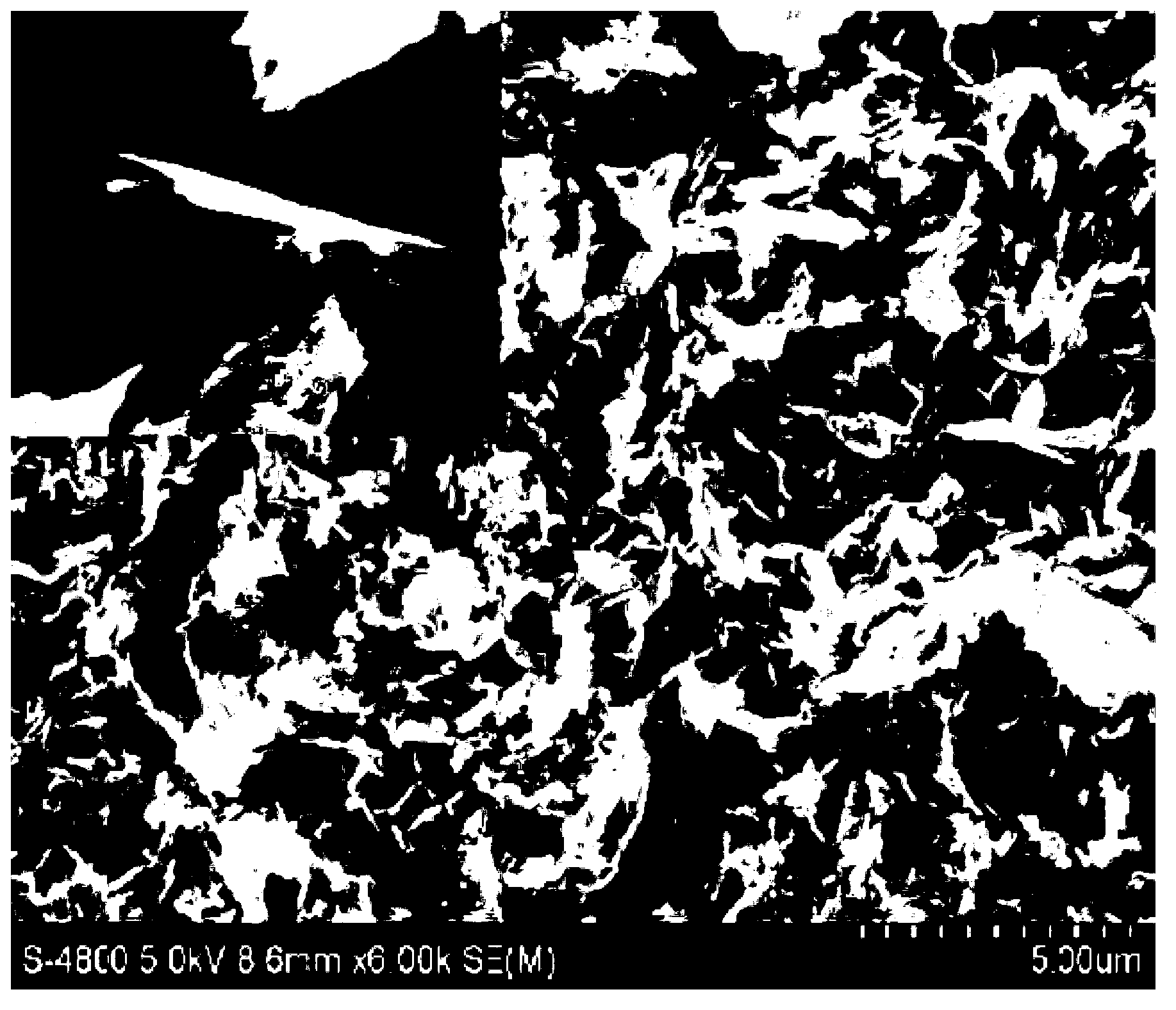

Image

Examples

Embodiment 1

[0034] A method for efficiently preparing graphene is realized through the following steps:

[0035] (1) Weigh 4g of expanded graphite and 40g of potassium nitrate, the mass ratio of potassium nitrate to expanded graphite is 10:1;

[0036] (2) Add potassium nitrate and expanded graphite into a beaker with 80 mL of distilled water, heat and mix evenly until the potassium nitrate is completely dissolved, then place the beaker in a drying oven until all the water evaporates to obtain a mixture of expanded graphite and potassium nitrate, and then Put the mixture of expanded graphite and potassium nitrate into a ball mill jar with a volume of 1000mL, and add zirconium balls according to the ball-to-material mass ratio of 25:1;

[0037] (3) Then install the ball milling jar on the stirring ball mill, mill at a speed of 70 rpm for 2 hours, and pour out the ball milling product and zirconium balls from the ball milling jar;

[0038] (4) Rinse the ball milled product and zirconium bal...

Embodiment 2

[0040] A method for efficiently preparing graphene is realized through the following steps:

[0041] (1) Weigh 2g of expanded graphite, weigh 40g of potassium chloride, and the mass ratio of potassium chloride to expanded graphite is 20:1;

[0042] (2) Add potassium chloride and expanded graphite into a beaker with 100mL of distilled water, heat and mix evenly until potassium chloride is completely dissolved, and then place the beaker in a drying oven until all the water evaporates to obtain a mixture of expanded graphite and potassium chloride. mixture, then the mixture of expanded graphite and potassium chloride is put into a ball mill jar with a volume of 1000mL, and zirconium balls are added according to the ball-to-material mass ratio of 25:1;

[0043] (3) Then install the ball mill jar on the stirring ball mill, mill at a speed of 70 rpm for 3 hours, and pour out the ball mill product and zirconium balls from the ball mill jar;

[0044] (4) Rinse the ball milled product...

Embodiment 3

[0046] A method for efficiently preparing graphene is realized through the following steps:

[0047] (1) Weigh 1.5g of expanded graphite, weigh 45g of sodium sulfate, and the mass ratio of sodium sulfate to expanded graphite is 30:1;

[0048] (2) Add sodium sulfate and expanded graphite into a beaker with 120mL of distilled water, heat and mix evenly until the sodium sulfate is completely dissolved, then place the beaker in a drying oven until all the water evaporates to obtain a mixture of expanded graphite and sodium sulfate, and then Put the mixture of expanded graphite and sodium sulfate into a ball mill jar with a volume of 1000mL, and add zirconium balls according to the mass ratio of balls to materials of 50:1;

[0049] (3) Then install the ball mill jar on the stirring ball mill, mill at a speed of 70 rpm for 8 hours, and pour out the ball mill product and zirconium balls from the ball mill jar;

[0050] (4) Rinse the ball milled product and zirconium balls poured out i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com