Crystallization device of sodium fluoride

A crystallization device and sodium fluoride technology, applied in the direction of alkali metal fluoride, can solve the problems of uncontrollable crystal particle size, low crystallization rate, and long crystallization time, so as to shorten the crystallization time, increase the crystallization rate, and reduce the crystallization speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

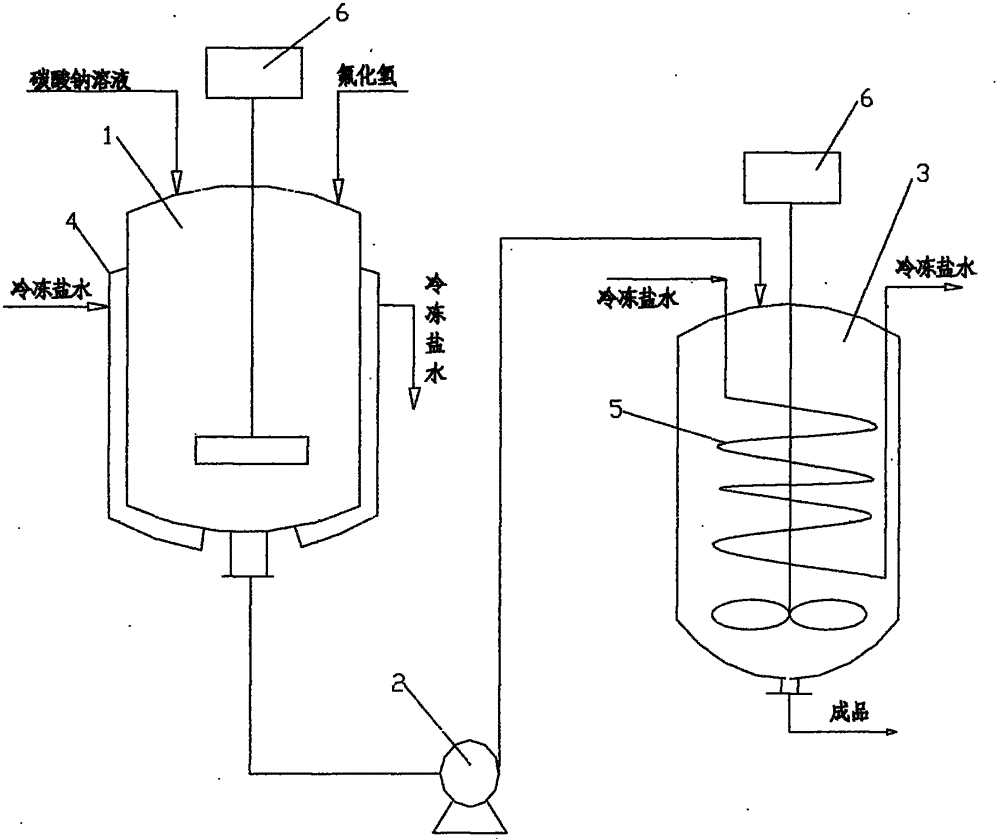

[0013] A sodium fluoride crystallization device, mainly composed of a reaction tank 1, a feeding pump 2 and a middle tank 3, the outer surface of the reaction tank 1 is provided with a jacket 4, the inside of the middle tank 3 is provided with a coil 5, the jacket 4 and the coil 5 are all passed into frozen brine.

[0014] When the device of the present invention is in use, sodium carbonate solution and hydrogen fluoride gas are sent to the reaction tank 1 for reaction, and the temperature in the reaction tank 1 can be controlled at 40 to At 43°C, the reaction material is sent to the middle tank 3 through the feeding pump 2, and the coil 5 in the middle tank 3 is fed with a cooling medium to further cool the reaction material, so that sodium fluoride crystals are obtained at the bottom of the middle tank 3. The crystallization device of the present invention can adjust the cooling rate of the sodium fluoride solution by controlling the flow rate of the frozen brine in the jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com