Device and method for sludge treatment

A sludge and reactor technology, applied in the oxidation treatment of sludge, sludge treatment, chemical instruments and methods, etc., can solve problems such as low sludge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

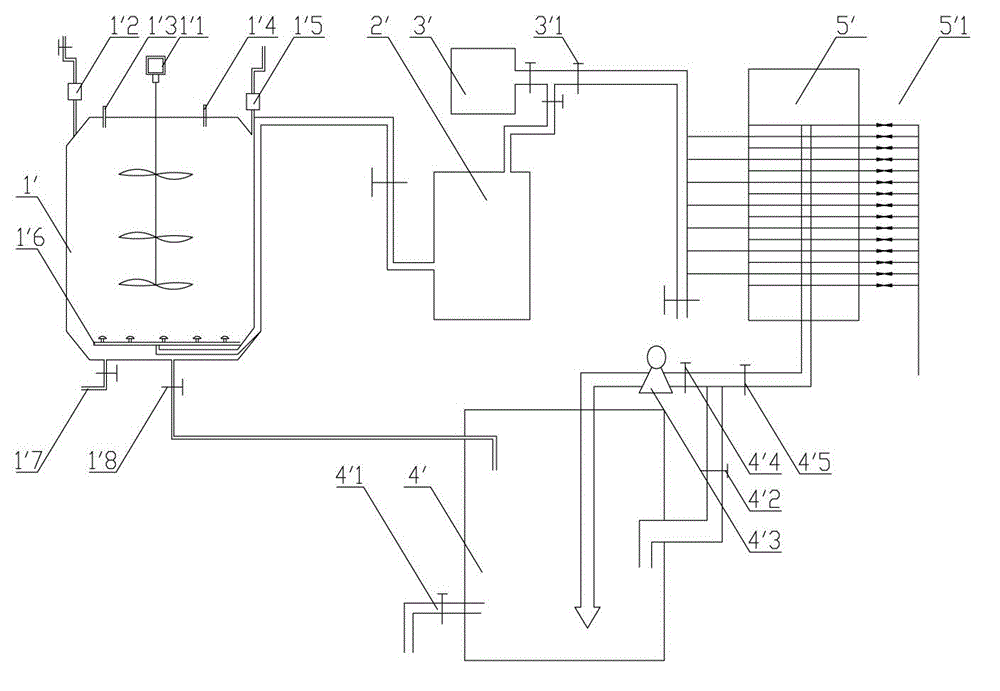

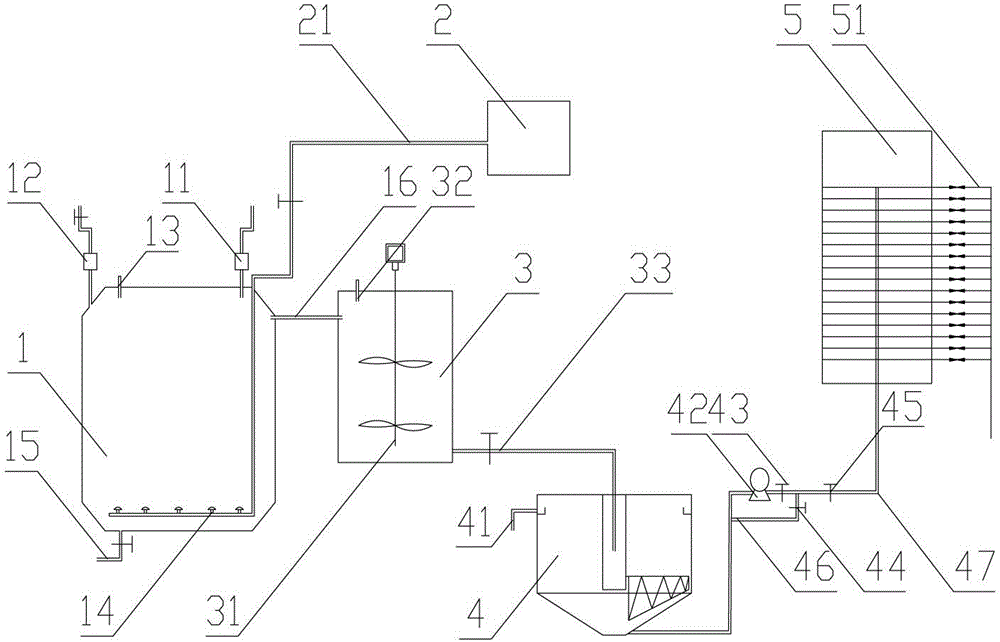

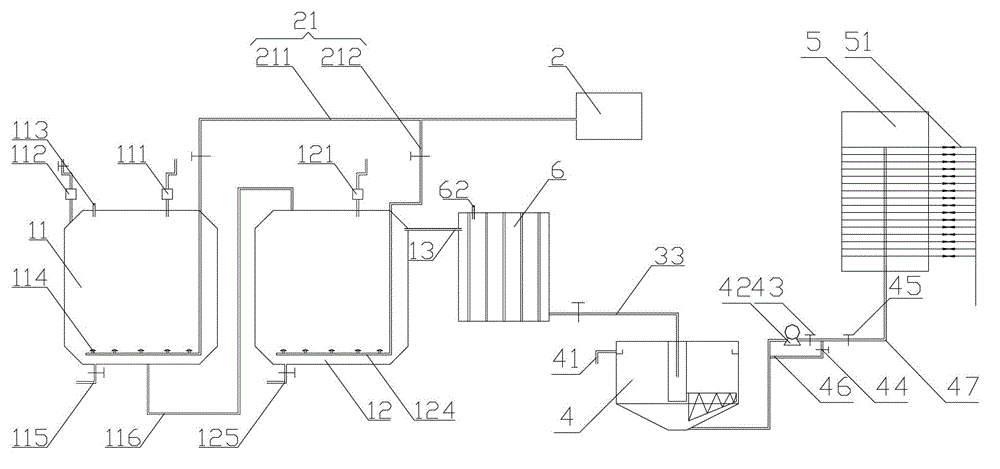

Image

Examples

Embodiment 1

[0091] Toner and FeCl with a mass ratio of 80:20 3 Mixing and mixing evenly to obtain an oxidation-guided catalyst;

[0092] Pass the sludge to be treated into the membrane rupture reactor through the sludge feed port, add the oxidation-directed catalyst prepared in this embodiment into the membrane rupture reactor through the oxidation reaction material feed port, stir and react, and then pass the ozone The generator feeds ozone into it to carry out redox reaction; the oxidation-guiding catalyst accounts for 5% of the total mass of the dry basis, and the amount of ozone introduced is based on the dry basis mass of the excess sludge: one kilogram of the excess sludge is dry Pass 0.5 grams of ozone into the base;

[0093] The product of the redox reaction obtained is transported in the coagulation reactor, and FeCl containing 50wt% is added thereto through the coagulation agent feeding port. 3 , the coagulation agent of the PAC of 40wt% and the CPAM of 10wt%, the add-on of co...

Embodiment 2

[0096] This embodiment is carried out with reference to the technical scheme of Example 1, the difference is that the oxidation-guiding catalyst in this embodiment is a mixture of activated carbon powder, fly ash, iron formate and aluminum formate with a mass ratio of 35:40:10:15, and the oxidation The addition amount of guide catalyst is 3.5% of the total mass of excess sludge on a dry basis, and the input amount of ozone is based on the dry basis mass of excess sludge: 0.8 grams of ozone equivalent is introduced into one kilogram of this excess sludge on a dry basis;

[0097] The coagulation agent that present embodiment adopts is the FeCl that contains 55wt% 3 , 35wt% PAC and 10wt% CPAM.

Embodiment 3

[0099] This embodiment is carried out with reference to the technical scheme of Example 1, the difference is that the oxidation-guiding catalyst in this embodiment is carbon powder, FeCl 3 and iron acetate, the amount of oxidation-guiding catalyst added is 6.5% of the total mass of the excess sludge on a dry basis, and the amount of ozone introduced is based on the mass of the excess sludge on a dry basis: one kilogram of the excess sludge on a dry basis is passed through Into 0.3 grams of ozone equivalent;

[0100] The coagulation agent that present embodiment adopts is the FeCl that contains 45wt% 3 , 35wt% PAC and 20wt% CPAM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com