Ore melting furnace quantitative feeding device

A technology of a feeding device and a melting furnace, which is applied to the charging of the melting furnace, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of the acceleration speed cannot be effectively controlled, the rotary mechanism is blocked, and the product output is affected, and the structure is simple, Precise dosing and low scrap rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

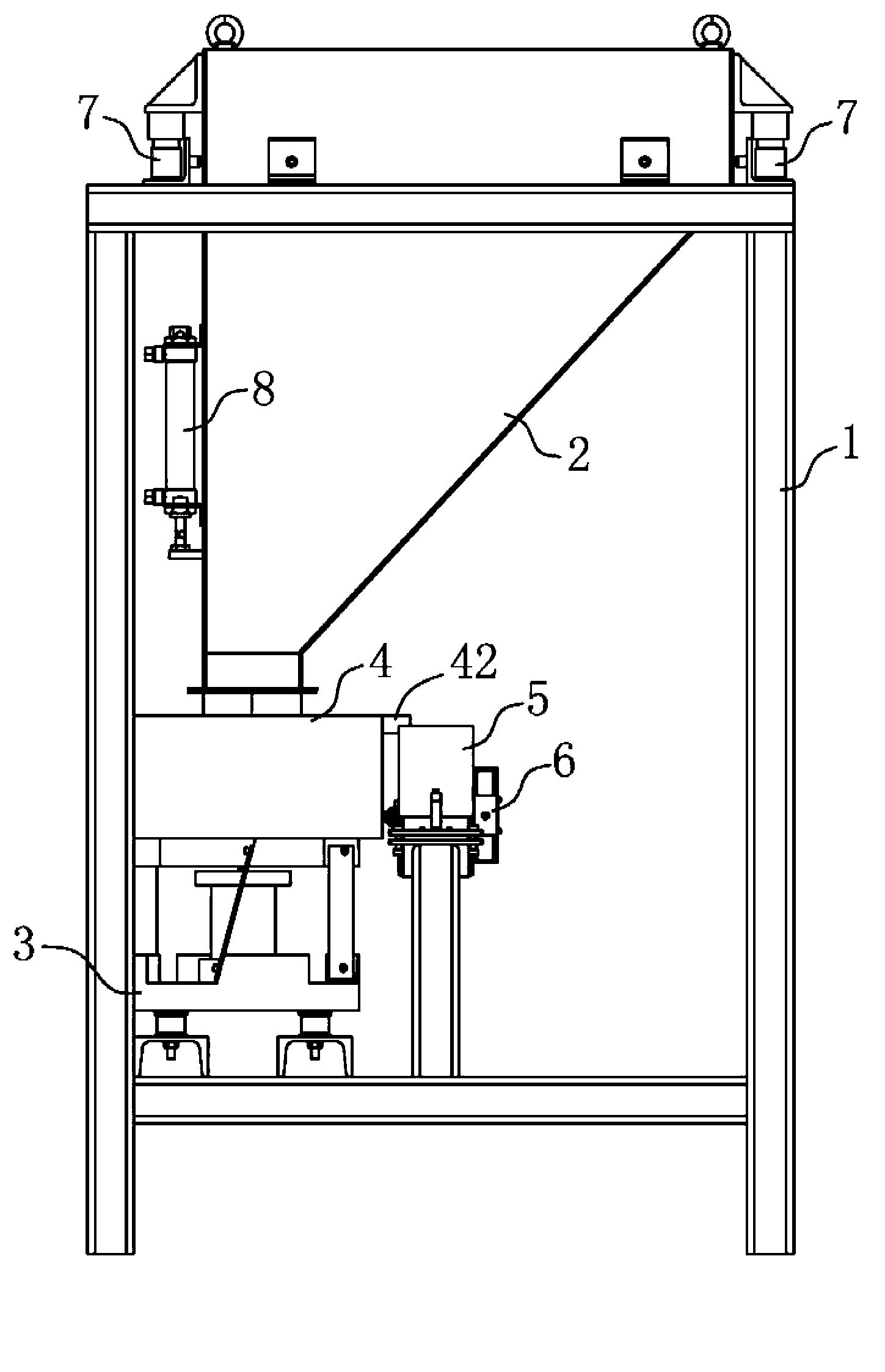

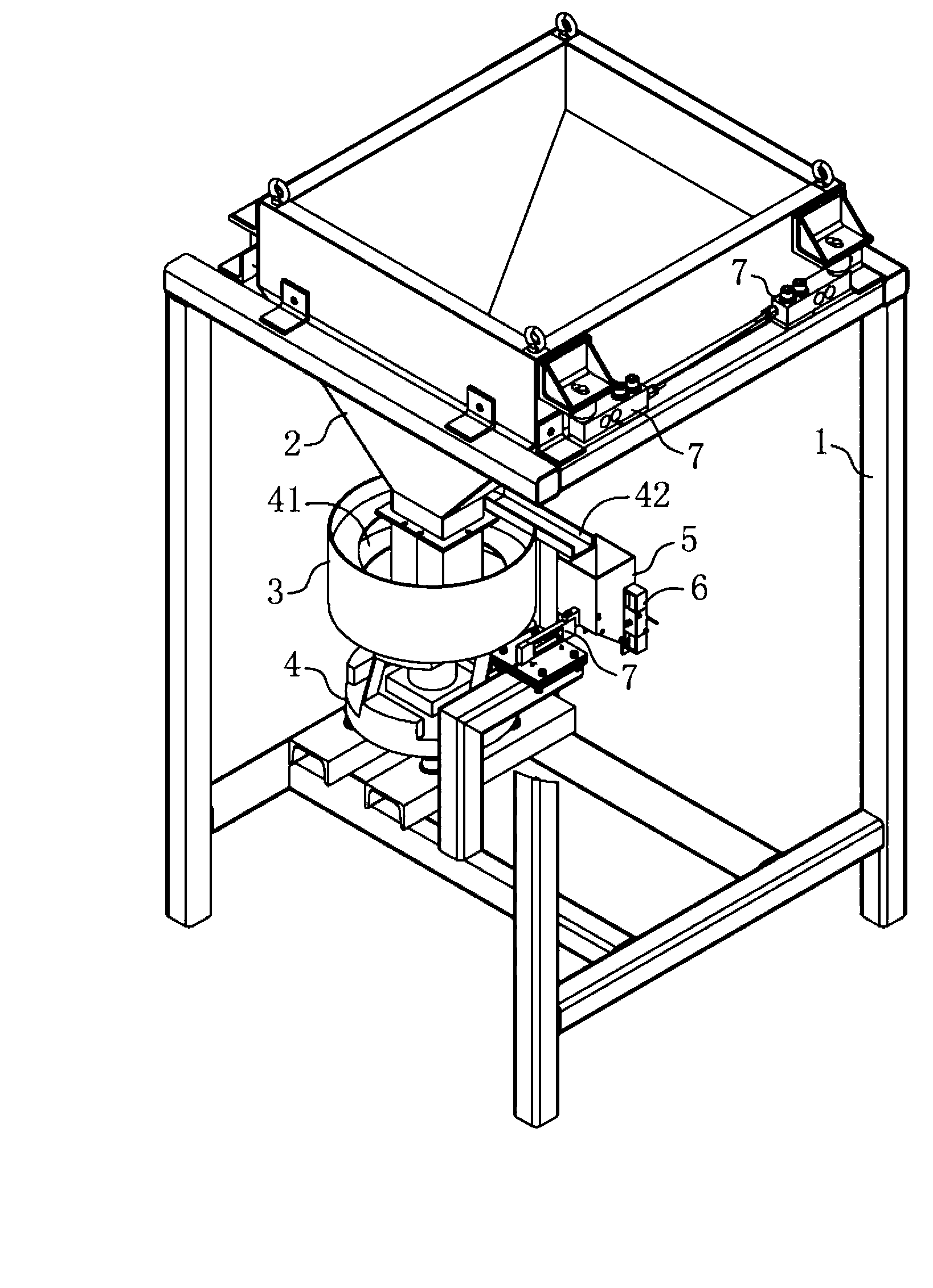

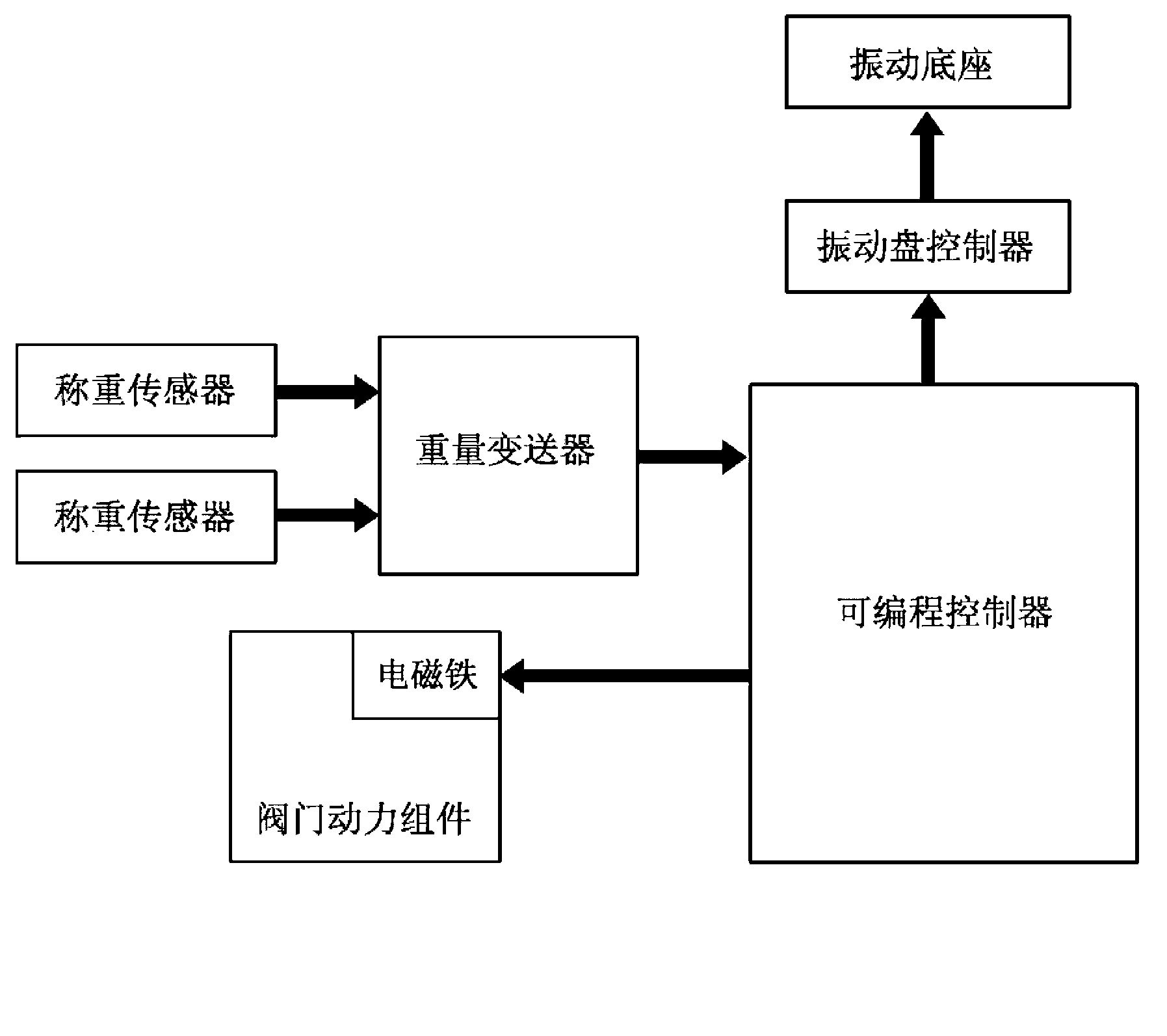

[0020] refer to figure 1 , figure 2 As shown, one embodiment of the present invention is a quantitative feeding device for an ore melting furnace. This device first needs to be provided with a material rack 1, and a funnel-shaped feed bin 2 is installed on the feed rack 1, and the top of the feed bin 2 is open, so that Add materials in batches for temporary storage; and the rack 1 is also equipped with a vibration base 3 and a screw top plate 4, wherein the screw top plate 4 is placed under the feed bin 2, and the vibration base 3 is placed under the screw top plate 4; The vibrating base 3 and the screw top plate 4 are mutually connected and fixed, and a spiral channel 41 is set inside the screw top plate 4 ( figure 1 not shown); and the discharge port at the lower end of the bin 2 needs to extend to the vicinity of the bottom of the screw top plate 4, and keep a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com