A production line for ultra-low expansion glass-ceramics

A glass-ceramic and production line technology, which is applied in the field of lithium-aluminum-silicon ultra-low expansion glass-ceramics and manufacturing laser navigation equipment, and can solve the problems of non-continuous production of glass-ceramic industrial production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

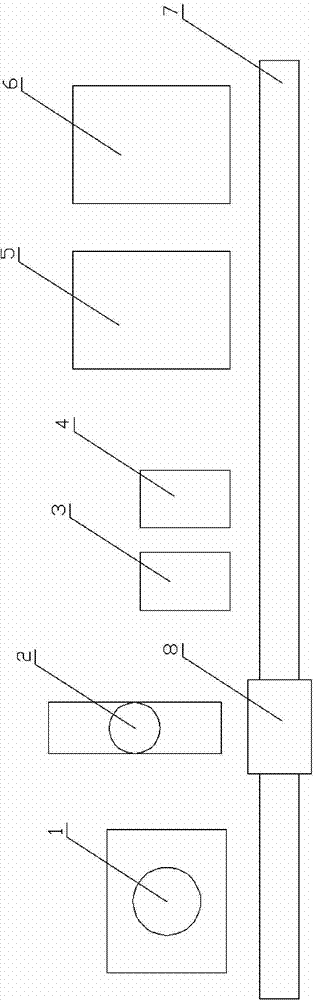

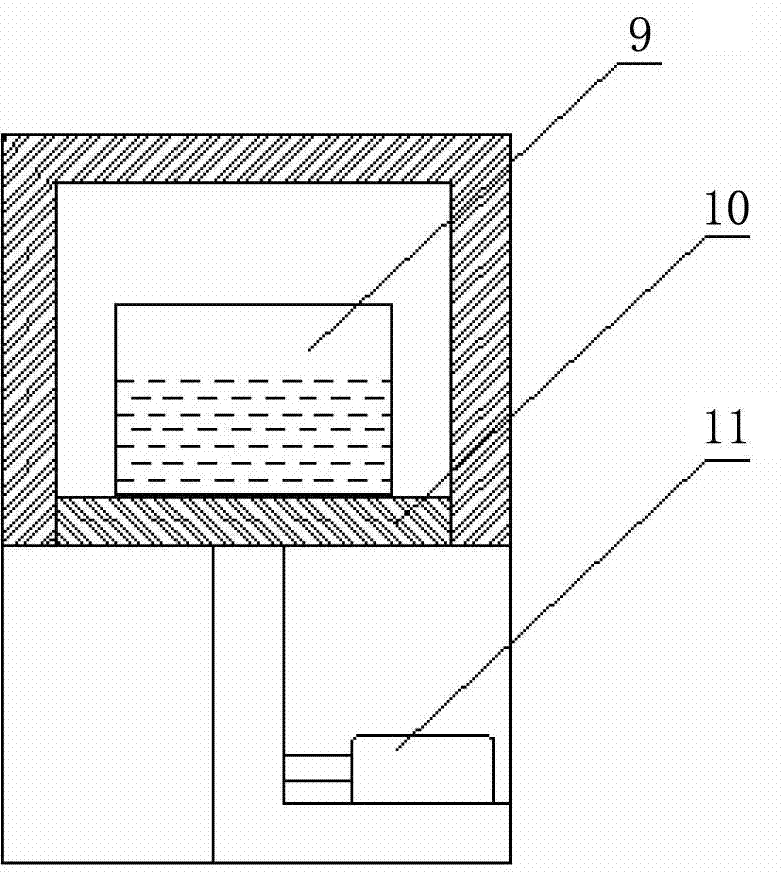

[0023] In order to realize the industrialized production of ultra-low expansion glass-ceramic, the present invention provides a complete set of industrial production line capable of realizing continuous production, which is composed of melting furnace, molding machine, annealing furnace, crystallization furnace, conveying device and track, etc. The role of the device and the track is to connect the processes between the melting furnace, molding machine, annealing furnace and crystallization furnace, so that the production can be carried out continuously.

[0024] In addition, the present invention also provides a production method of ultra-low expansion glass-ceramic, which is composed of melting process, homogenization process, clarification process, glass forming process, annealing process and microcrystallization heat treatment process. According to the present invention, the melting, homogenizing and clarifying processes are all completed in the melting furnace, the glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com