Method for establishing aromatic hydrocarbon production flow model

A production process and model technology, applied in organic chemistry, distillation purification/separation, adsorption purification/separation, etc., can solve the problems of inaccurate aromatic hydrocarbon production process model, unable to reflect the real product composition, unable to reflect the real product composition and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

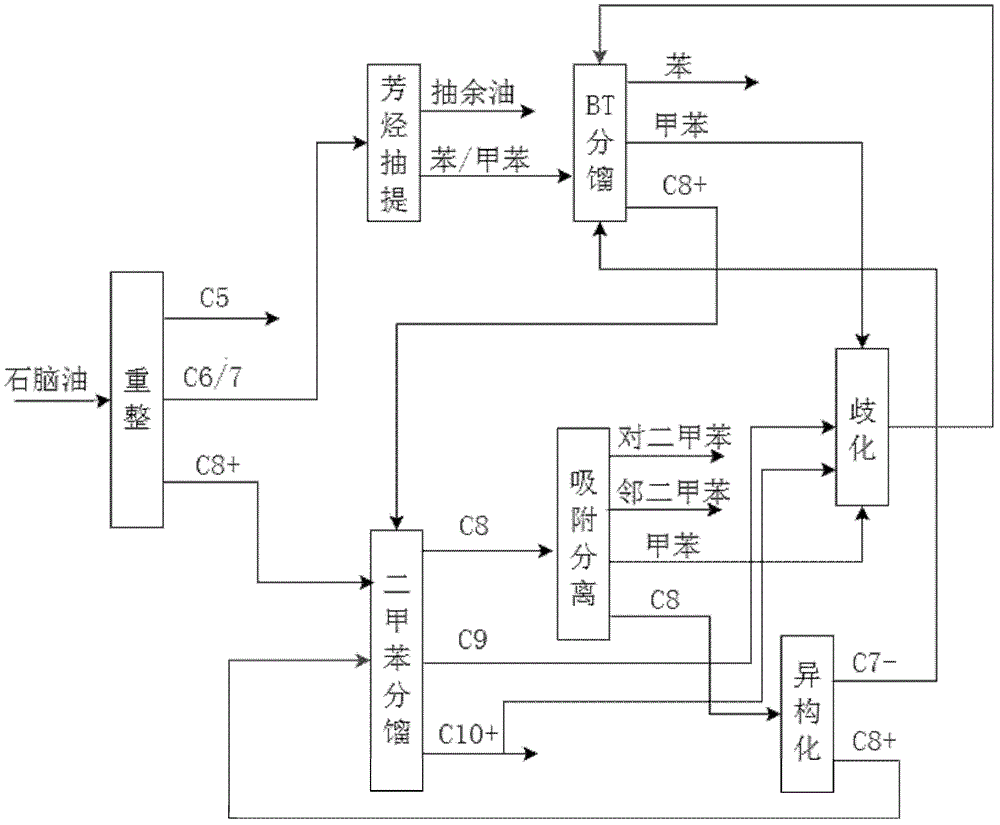

[0010] figure 1 A flow chart showing the aromatics production process. Such as figure 1 As shown, naphtha is separated into carbon 5 (C5) stream, C6 / C7 stream and C8+ stream by reforming unit. The C5 stream flows out, and the C6 / C7 stream enters the aromatics extraction unit, and the separated products are raffinate, a mixture of benzene and toluene. The extracted benzene and toluene mixture enters the BT fractionation tower. In addition, the disproportionation reactants also enter the BT fractionation tower to separate benzene, toluene and C8+ streams. The benzene flows out. The toluene is used as the raw material for the transalkylation and disproportionati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com