Micro/nano-scale sheet type titanium polyester catalyst and application thereof

A micro-nano-scale, titanium-based polyester technology, applied in the field of titanium-based polyester catalysts, can solve problems such as high cost, poor dispersion, and easy hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

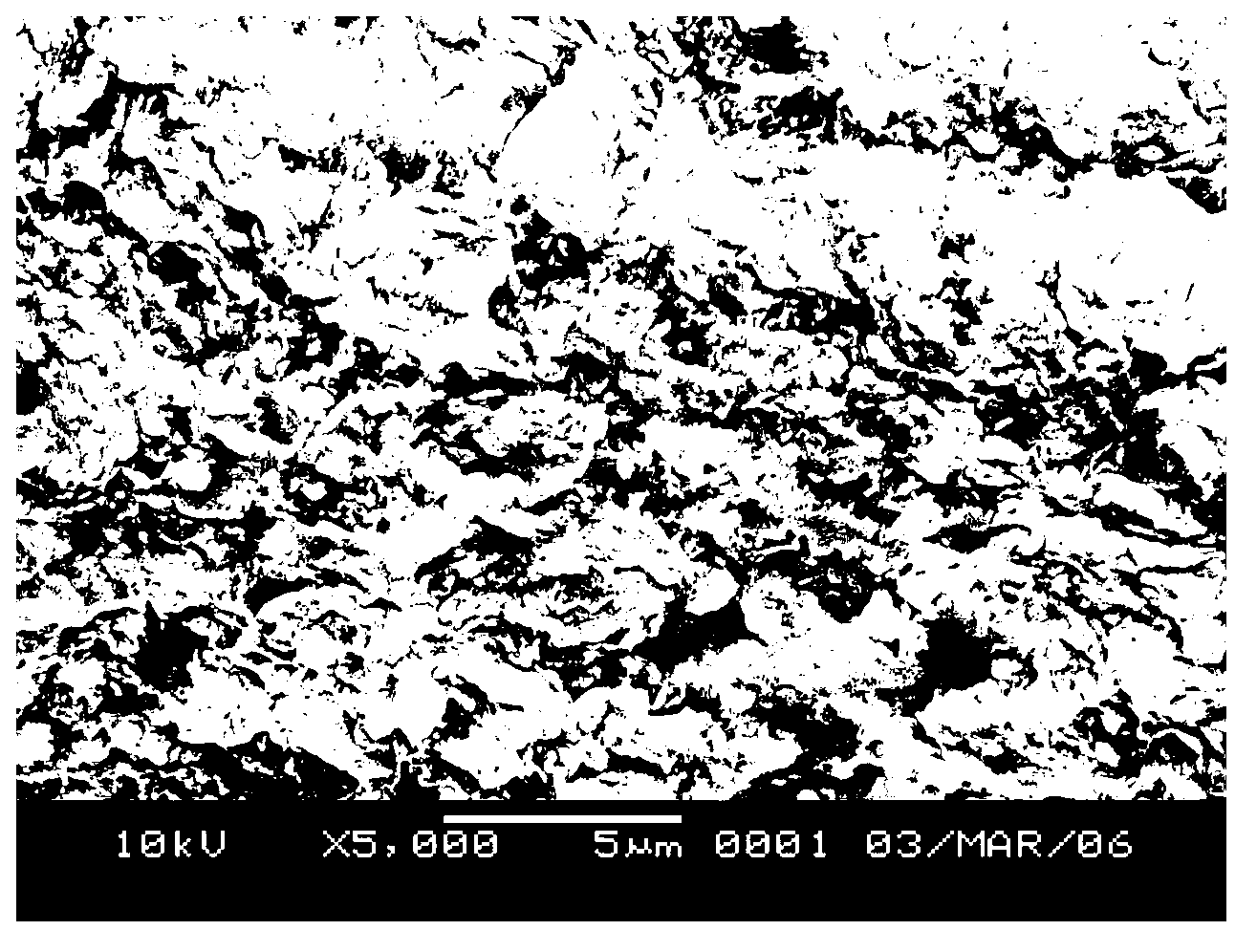

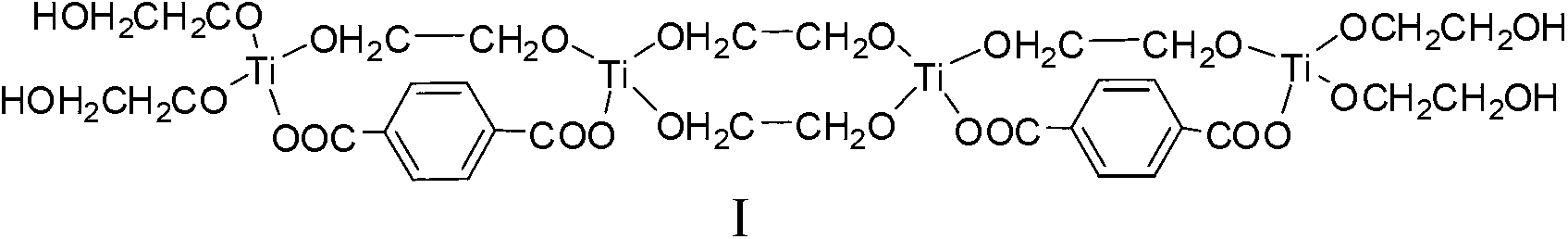

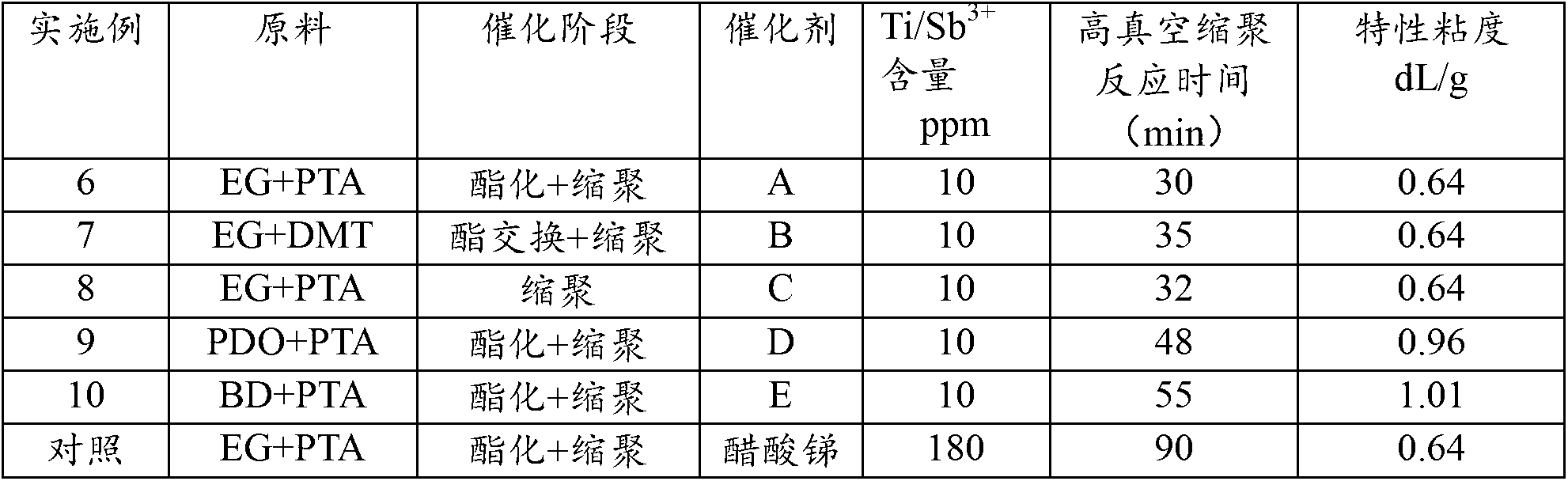

[0029] Add 23g of n-butyl titanate to 498g (3mol, 1eq), terephthalic acid and 279g (4.5mol, 1.5eq) of ethylene glycol, under 0.1MPa gauge pressure, 150°C temperature control reaction for 1.2h, then raise the temperature Continue to react at about 260°C. Collect the distilled liquid during the esterification reaction, and stop the reaction when the mole number of water in it is twice that of terephthalic acid (that is, the degree of esterification is about 100%). The reaction system is cooled, and the solid therein is collected, which is an organotitanium compound Ti 4 (OCH 2 CH 2 O) 8 (OCOC 6 h 4 COO) 2 h 4 The complex dispersed in BHET with nanosheet structure, its scanning electron microscope see figure 1 . Further, the solid is ground or pulverized into powder, that is, titanium-based polyester catalyst A.

Embodiment 2

[0031] Dissolve the BHET of the complex in Example 1 with a 1:1 weight ratio of phenol-tetrachloroethane solution, centrifuge, and collect the insoluble matter that is the organic titanium compound Ti 4 (OCH 2 CH 2 O) 8 (OCOC 6 h 4 COO) 2 h 4 , the mixture of the compound and ethylene glycol is the titanium-based polyester catalyst B.

Embodiment 3

[0033] The slurry obtained by mixing the compound in Example 1 with ethylene glycol is the titanium-based polyester catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com