Material for producing handicrafts and preparation method thereof

A technology for handicrafts and pigment powder, which is applied in the field of making handicraft materials, can solve the problems of low cost of impact strength, and achieve the effects of low cost, reduced difficulty, high toughness and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

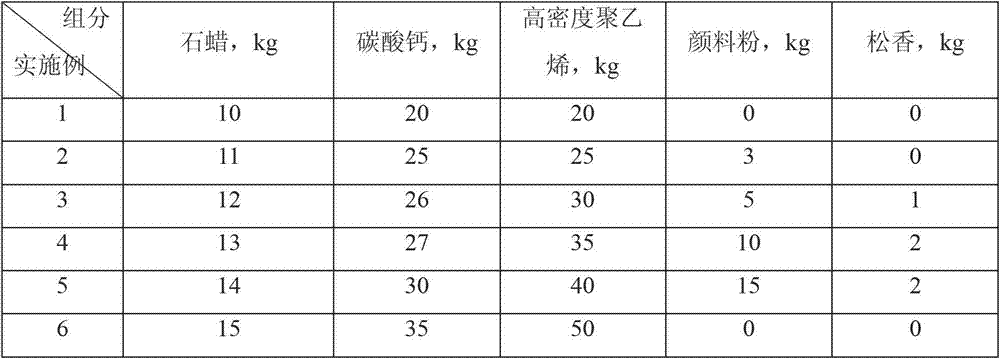

Examples

Embodiment 2

[0024] For the preparation method of Example 2, first heat the paraffin wax to 60°C to melt, then add polyethylene to mix, heat up to 150°C to melt, then add calcium carbonate to mix at a constant temperature, and finally add pigment powder at 200°C, melt and stir evenly to obtain finished product.

[0025] For the preparation method of Examples 3-5, first heat the paraffin wax to 65°C to melt, then add polyethylene to mix, heat up to 220°C to melt, then add calcium carbonate to mix at a constant temperature, and finally add pigment powder and crushed rosin at 220°C , melted and stirred evenly to obtain the finished product.

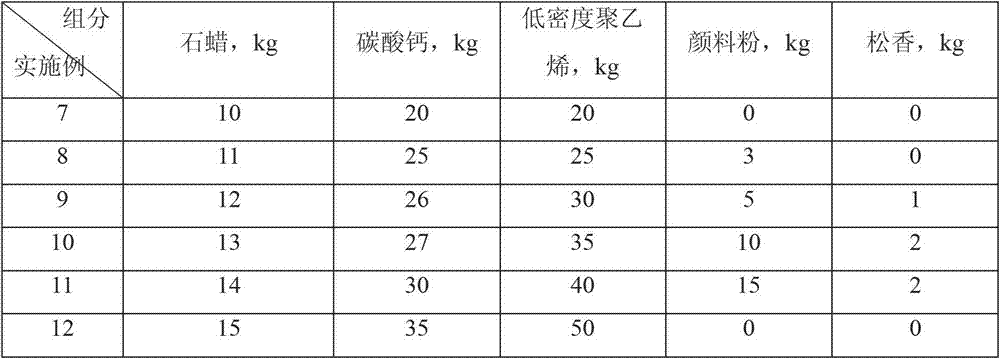

[0026] Table 2

[0027]

[0028] For the preparation method of Examples 7 and 12, first heat the paraffin wax to 50°C to melt, then add polyethylene to mix, heat up to 110°C to melt, then add calcium carbonate to mix, melt, and stir evenly to obtain the finished product.

Embodiment 8

[0029] For the preparation method of Example 8, first heat the paraffin wax to 60°C to melt, then add polyethylene to mix, heat up to 150°C to melt, then add calcium carbonate to mix at a constant temperature, and finally add pigment powder at 200°C, melt and stir evenly to obtain finished product.

[0030] For the preparation method of Examples 9-11, first heat the paraffin wax to 65°C to melt, then add polyethylene to mix, raise the temperature to 220°C to melt, then add calcium carbonate to mix at a constant temperature, and finally add pigment powder and pulverized rosin at 220°C , melted and stirred evenly to obtain the finished product.

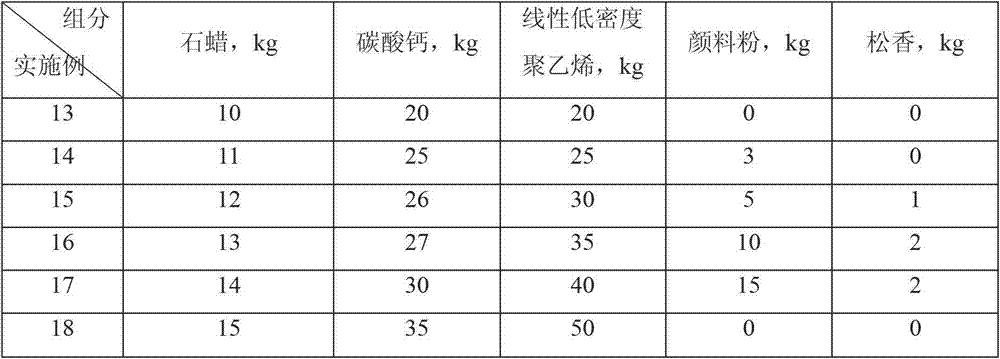

[0031] table 3

[0032]

[0033] For the preparation methods of Examples 13 and 18, first heat the paraffin wax to 50°C to melt, then add polyethylene to mix, heat up to 110°C to melt, then add calcium carbonate to mix, melt, and stir evenly to obtain the finished product.

Embodiment 14

[0034] For the preparation method of Example 14, first heat the paraffin wax to 60°C to melt, then add polyethylene to mix, raise the temperature to 150°C to melt, then add calcium carbonate to mix at a constant temperature, and finally add pigment powder at 200°C, melt and stir evenly. finished product.

[0035] For the preparation method of Examples 15-17, first heat the paraffin wax to 65°C to melt, then add polyethylene to mix, heat up to 220°C to melt, then add calcium carbonate to mix at a constant temperature, and finally add pigment powder and pulverized rosin at 220°C , melted and stirred evenly to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com