Siro compact spinning blended yarn of cotton crystal and long stapled cotton, and spinning technology thereof

A technology of Siro compact and crystal cotton, which is applied in the direction of yarn, textiles and paper making, can solve the problems of easy floating of fibers, high fiber rigidity, and fragility, and achieve good moisture absorption and dehumidification, mature technology, and broaden the market space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

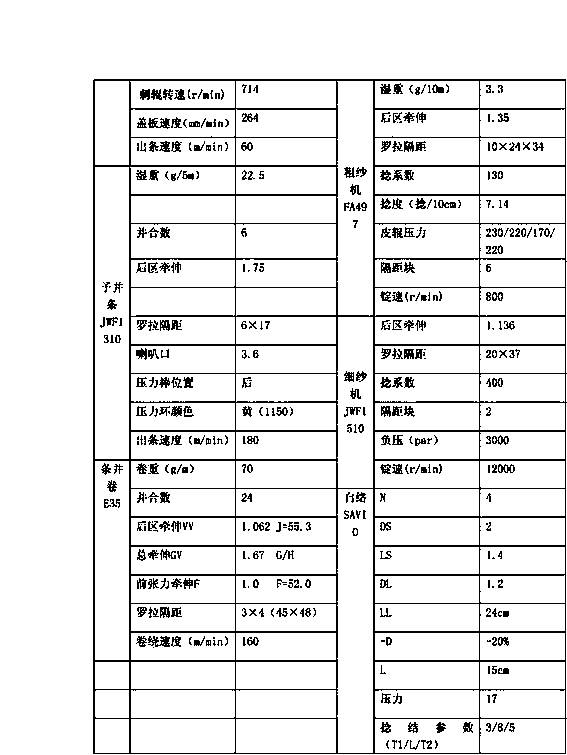

[0099] 1. Siro compact spinning crystal cotton / JC (long-staple cotton) 40 / 60 (dry weight%) 40S yarn

[0100] Body length mm Moisture % Strengthcn / tex Luminous flux Noil impurity content % total neps 16.0mm short fleece 12.7mm short fleece Micronaire tidiness% Spin stability parameter place of origin JC: 137 36.71 7.6 39.175 490.5 4.65 235 7.33 6.215 4.06 89 198.5 Xinjiang Crystal cotton 33mm

[0101] 2. Spinning process:

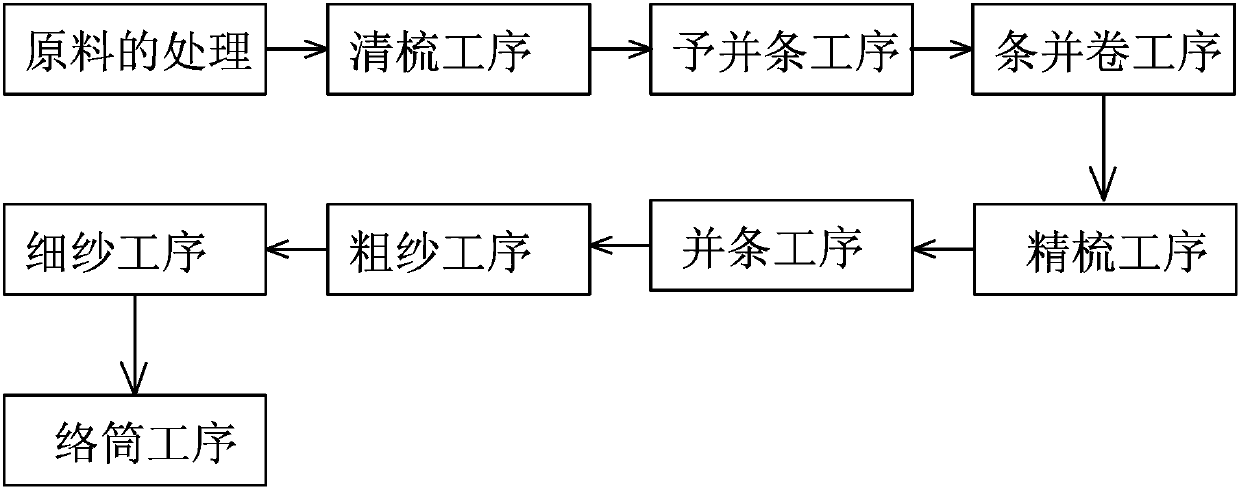

[0102] Crystal cotton / JC (long-staple cotton): health preservation of crystal cotton → crystal cotton and long-staple cotton are weighed and mixed according to the dry weight ratio of 2:3 (40% / 60%) → raw material opening (FW112 opening machine) → Mixing of raw materials (FN246B automatic wool feeding machine)→Carding and cleaning of raw materials (FA226A carding machine)→Drawing of sliver (JWF1310 drawing frame)→Synthesizing rolls (E35 sliver drawing frame)→Furth...

Embodiment 2

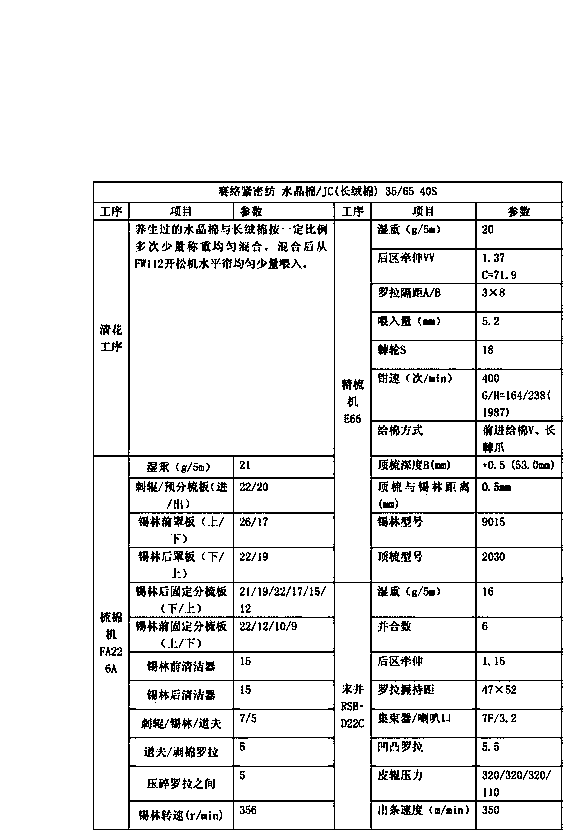

[0109] Embodiment 2 (best embodiment)

[0110] 2. Siro compact spinning crystal cotton / JC (long-staple cotton) 30 / 70 40S yarn

[0111] 1. Selection of raw materials

[0112] Body length mm Moisture % Strengthcn / tex Luminous flux Noil impurity content% total neps 16.0mm short fleece 12.7mm short fleece Micronaire tidiness% Spin stability parameter place of origin JC: 137 36.71 7.6 39.175 490.5 4.65 235 7.33 6.215 4.06 89 198.5 Xinjiang Crystal cotton 33mm

[0113] 2. Spinning process:

[0114] Crystal cotton / JC (long-staple cotton): health preservation of crystal cotton→weighing and mixing of crystal cotton and long-staple cotton at a ratio of 30:70→opening of raw materials (FW112 opening machine)→mixing of raw materials (FN246B automatic wool feeding machine )→Carding and cleaning of raw materials (FA22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com