Ternary complex waterproof moisture-permeable coating agent and use thereof

A waterproof and moisture-permeable, ternary composite technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems of insufficient moisture permeability and large dosage, and achieve good mechanical and physical properties, good compatibility, The effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

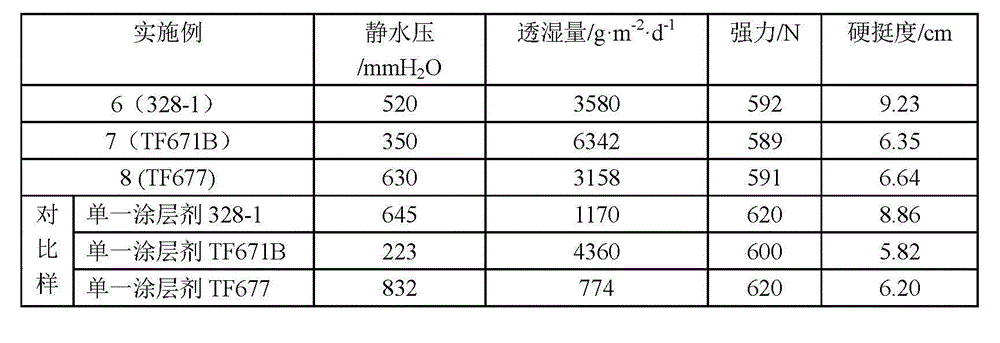

Examples

Embodiment 1

[0027] (1) Preparation of ternary composite coating agent:

[0028] a. Add 0.4g of synthetic thickener TF601A to 18g of water-based coating agent TF677, stir evenly with a magnetic stirrer, and set aside;

[0029] b. Add 3.6g of silk fibroin powder and 0.4g of polyvinylpyrrolidone into the thickened coating agent in a, and stir with a magnetic stirrer for 40 minutes to obtain a ternary composite coating agent.

[0030] c. Place the prepared ternary composite coating agent at room temperature and seal it for storage until use.

[0031] (2) Preparation of waterproof and moisture-permeable coated fabric:

[0032] a. For the pre-water-repellent finish of the polyester base fabric, the process formula and conditions are adopted: one dipping and one padding (water repellent DH819E 15g / L, padding rate 50%) → pre-baking (100°C, 3 min) → baking ( 170°C, 1 min), and the water-staining grade of the base fabric after finishing is 4-5.

[0033] b. Add 2g of cross-linking agent TF677 to ...

Embodiment 2

[0037] (1) Preparation of ternary composite coating agent:

[0038] a. Add 0.4g of synthetic thickener TF601A to 18g of water-based coating agent TF677, stir evenly with a magnetic stirrer, and set aside;

[0039] b. Add 1.8g of silk fibroin powder and 0.7g of polyvinylpyrrolidone to the thickened coating agent in a, and stir for 40 minutes with a magnetic stirrer to obtain a ternary composite coating agent.

[0040] c. Place the prepared ternary composite coating agent at room temperature and seal it for storage until use.

[0041] (2) Preparation of waterproof and moisture-permeable coated fabric:

[0042] The details are the same as the preparation of (2) waterproof and moisture-permeable coated fabric in Example 1.

Embodiment 3

[0044] (1) Preparation of ternary composite coating agent:

[0045] a. Add 0.4g of synthetic thickener TF601A to 18g of water-based coating agent TF677, stir evenly with a magnetic stirrer, and set aside;

[0046] b. Add 0.9g of silk fibroin powder and 2.7g of polyvinylpyrrolidone into the thickened coating agent in a, and stir for 40 minutes with a magnetic stirrer to obtain a ternary composite coating agent.

[0047] c. Place the prepared ternary composite coating agent at room temperature and seal it for storage until use.

[0048] (2) Preparation of waterproof and moisture-permeable coated fabric:

[0049] The details are the same as the preparation of (2) waterproof and moisture-permeable coated fabric in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com