Connecting method of metal roof plate and gutter and waterproof eave water baffle plate

A connection method and water retaining board technology, which is applied in the connection between metal roof panels and gutters, and in the field of waterproof cornice water retaining boards, can solve the problem of affecting the humidity of metal roof panels, not being able to adapt to the shape of the peaks and valleys of metal roof panels, and having no Fully meet the waterproof and moisture-proof properties of metal roofs, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

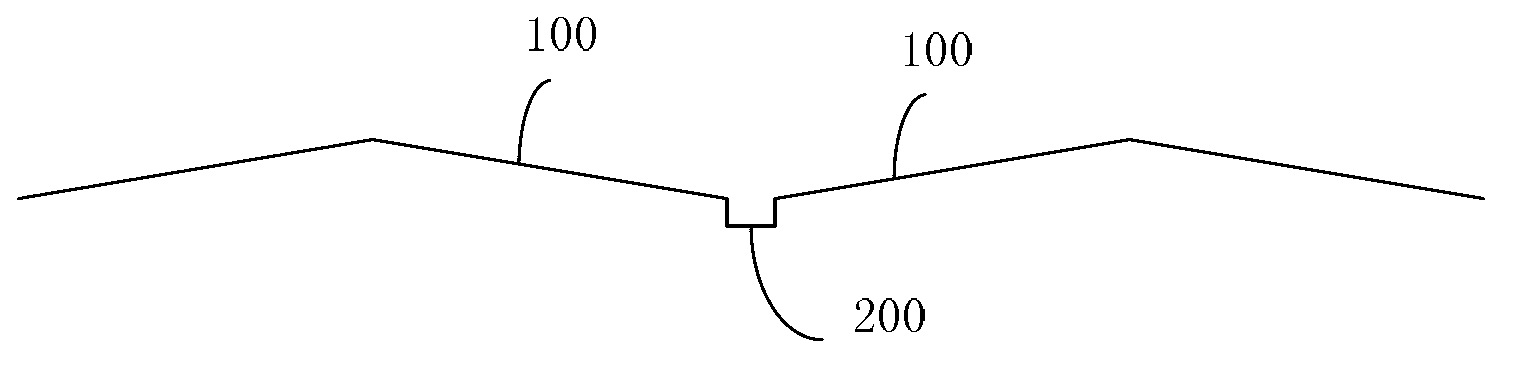

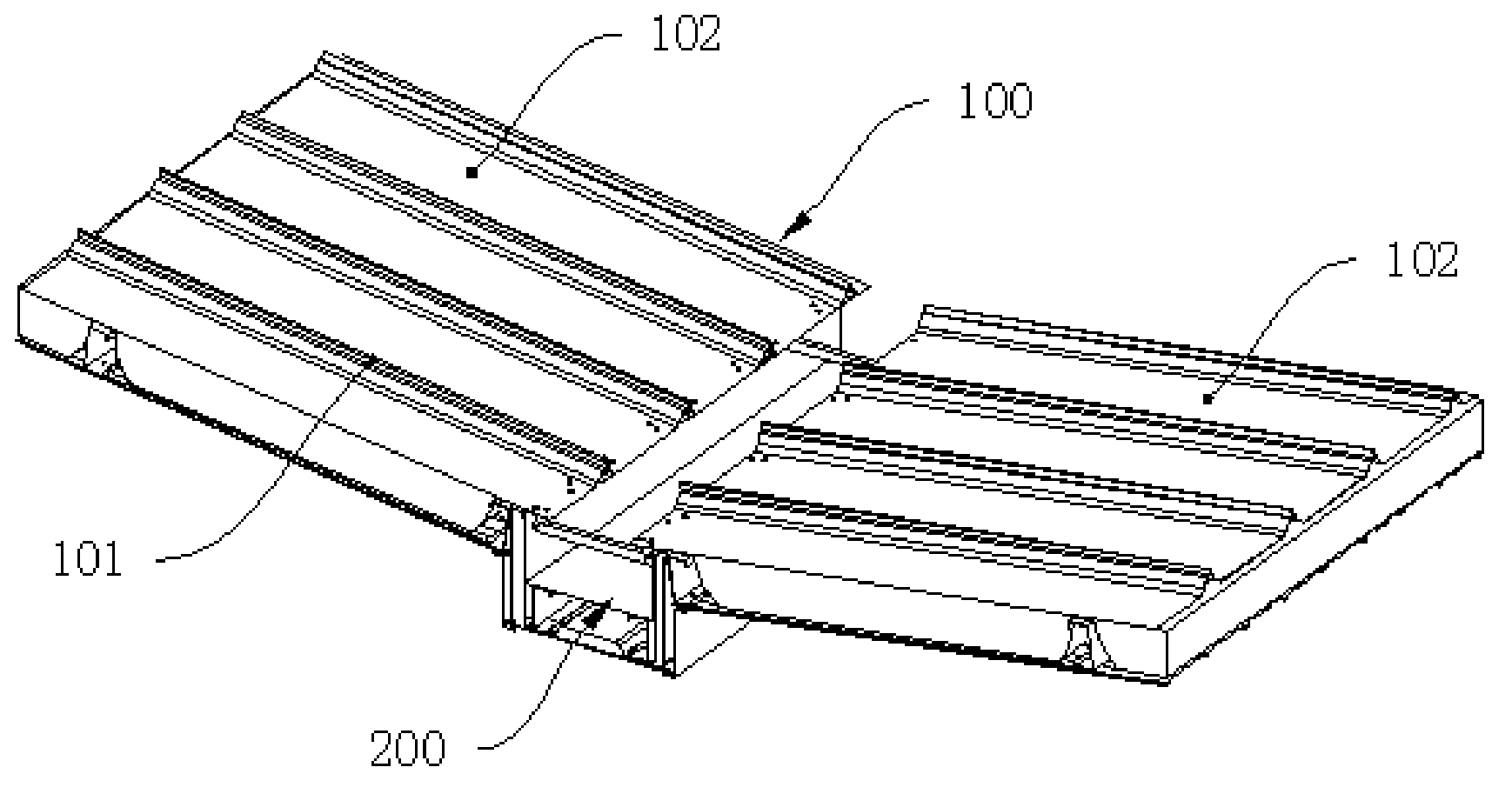

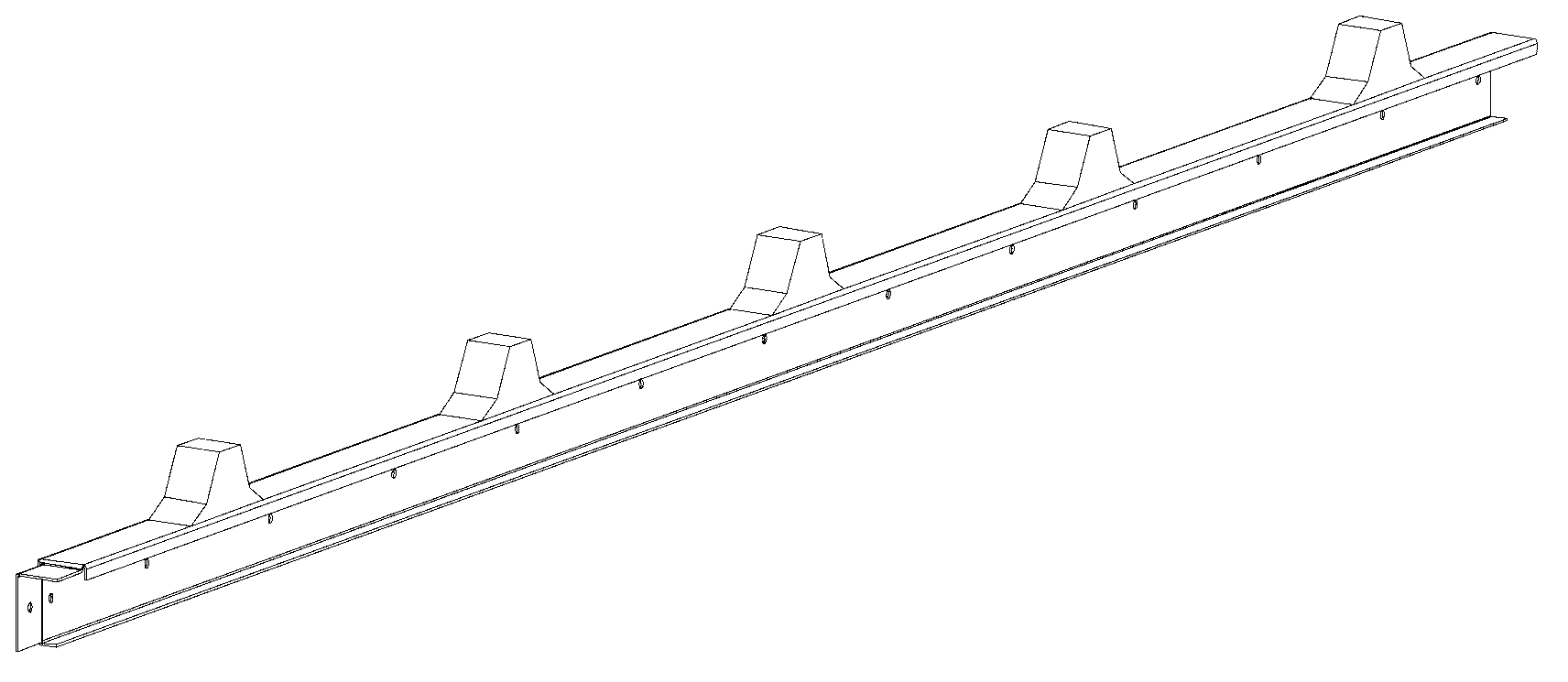

[0047] image 3 The structural diagram of the waterproof eaves water retaining plate provided by the present invention, Figure 4 for image 3 A local enlarged view, such as image 3 , Figure 4 As shown, the embodiment of the present invention provides a waterproof cornice water retaining board, which is used for the sealing connection between the metal roof panel and the gutter, which includes:

[0048] top horizontal plate 310;

[0049] A plurality of top sealing structures 320 are arranged on the upper surface of the top horizontal plate 310 to form a crest and trough structure matching the shape of the metal roof panel;

[0050] The left vertical plate 330 is connected to the left end of the top horizontal plate 310;

[0051] The left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com