Wireless monitoring system and method for modal parameter of blade of fan

A modal parameter, fan blade technology, applied in the testing of mechanical components, the testing of machine/structural components, signal transmission systems, etc. Monitors the effect of low power consumption, long service life, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

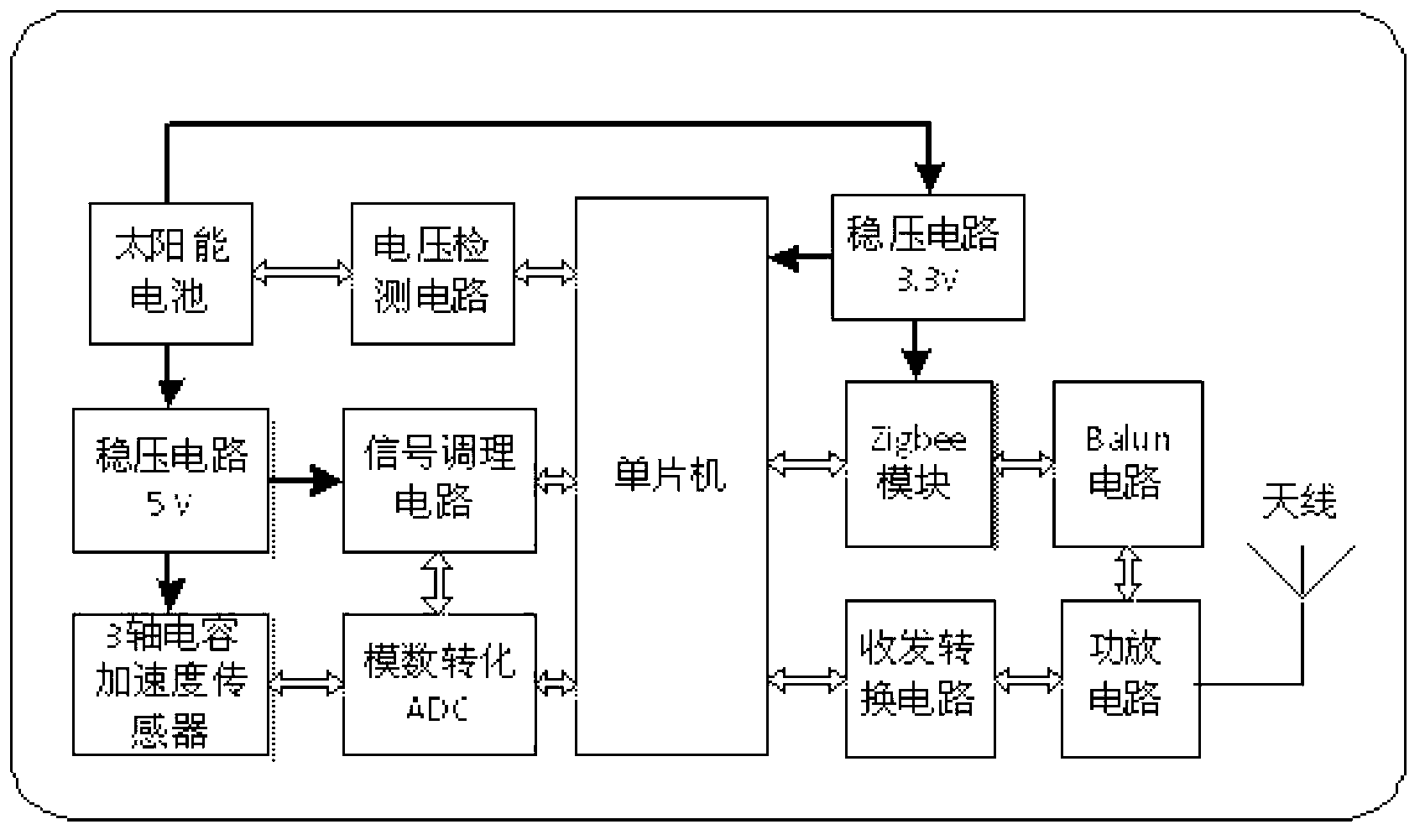

[0056] see Figure 5 As shown, an embodiment of the sensor of the present invention, the sensor of this embodiment adopts the CC2530 radio frequency single-chip microcomputer produced by Texas Instruments, and this chip integrates an 8051 single-chip microcomputer, AD digital-to-analog conversion module and ZigBee module.

[0057] The signal conditioning circuit adopts the LTC2053 operational amplifier, defines the amplification factor of the signal amplification circuit according to the quantitative relationship of its analog-to-digital conversion, and connects the amplified vibration acceleration analog signal to the CC2530 RF single-chip microcomputer, and its built-in 8051 single-chip microcomputer synchronously samples the 3-way vibration signal And AD conversion, the sampling frequency is 100Hz.

[0058] The power amplifier circuit is connected to the RF output pin of the CC2530 single-chip microcomputer, and the transceiver conversion circuit controls the transmit gain ...

Embodiment 2

[0061] see Image 6 As shown, an embodiment of the coordinator of the present invention, the coordinator adopts CC2530 single-chip microcomputer as the core unit. The ZigBee module is the same as the sensor. The MC34063 power module is used to convert the 24V DC power from the pitch control cabinet into a 3.3V power supply for CC2530.

[0062] The CP2101 chip is the core unit of the serial communication module, which is used to realize the serial communication and read the main control information of the fan. The built-in 8051 MCU of CC2530 controls the data, the IO port stores data to the SD card storage device, and the 8051 regularly starts the GPRS module to read the data in the SD card and perform remote data communication.

[0063] A wireless monitoring method for fan blade modal parameters of the present invention, the specific steps are:

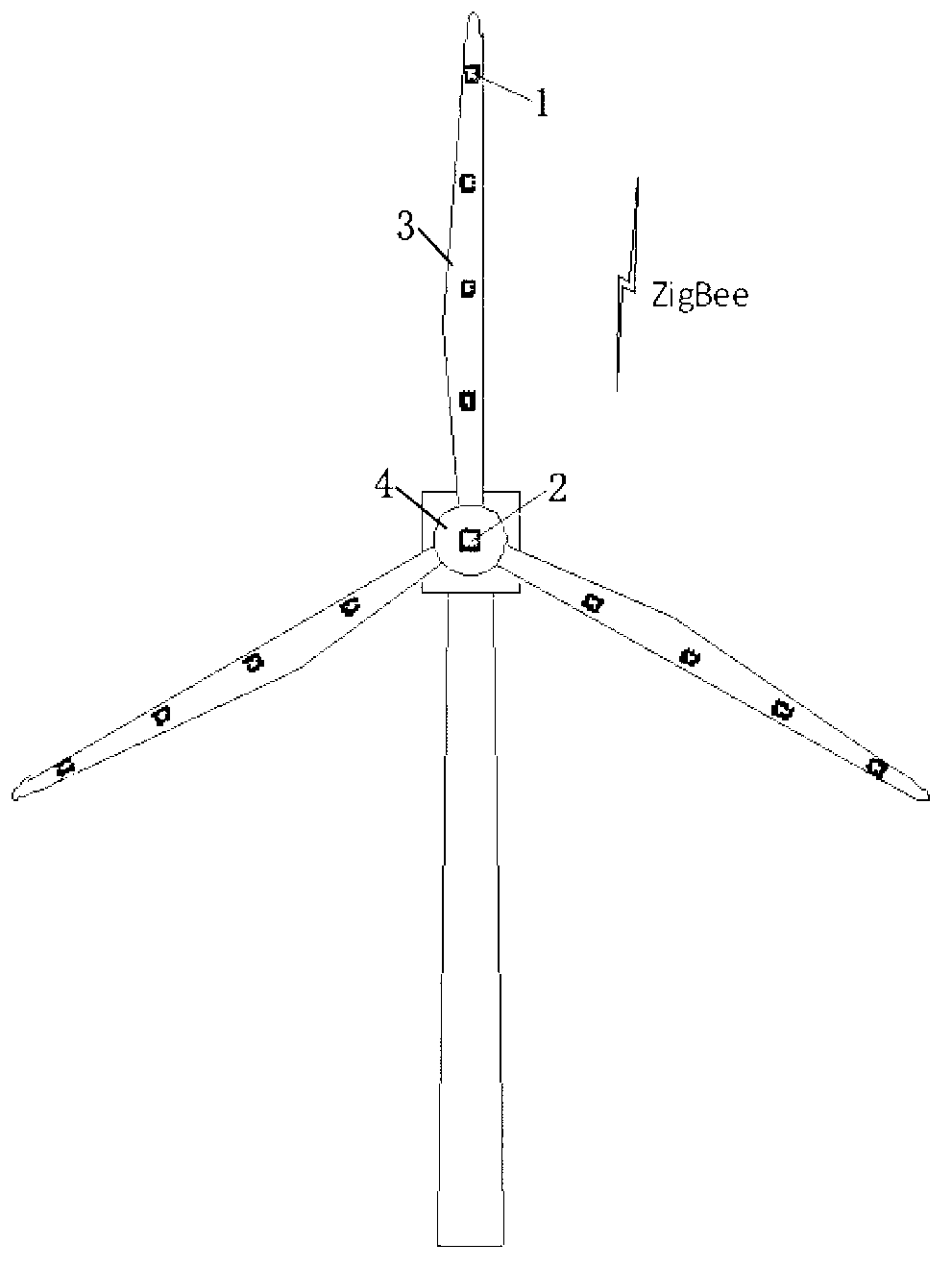

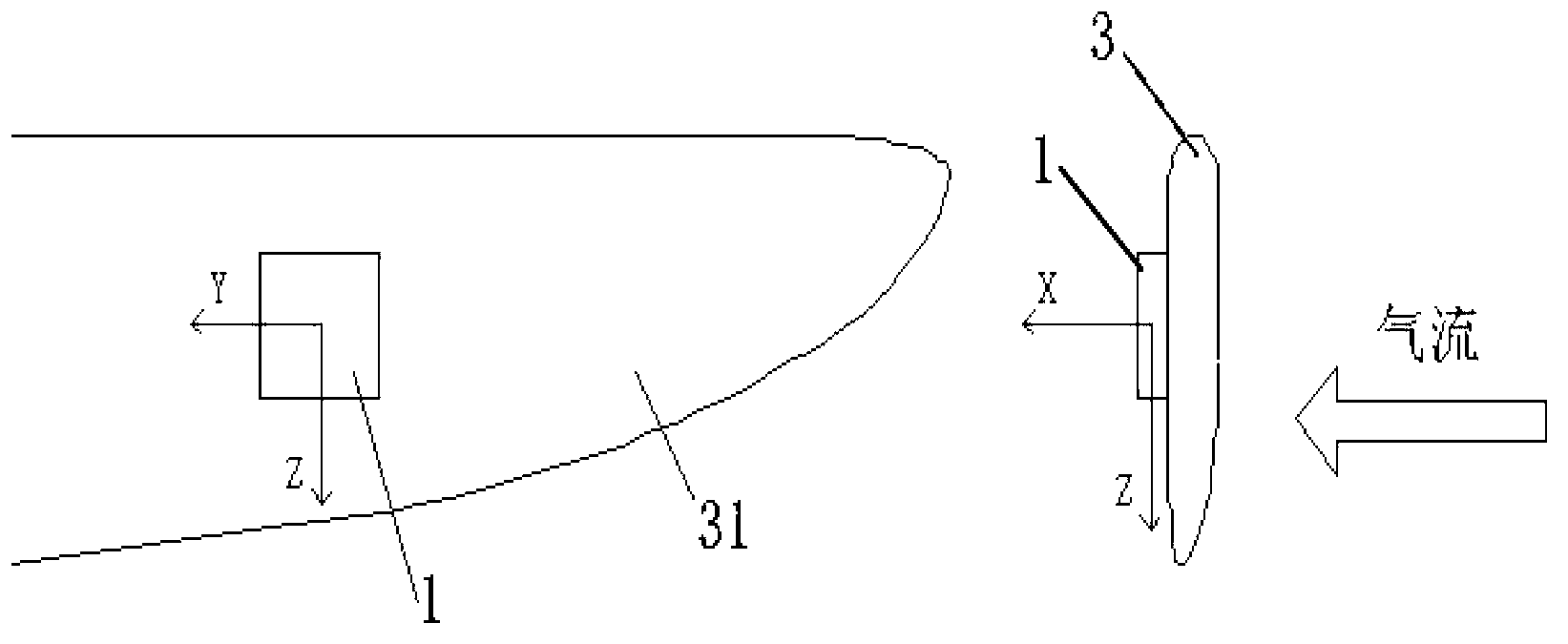

[0064] A. By installing sensors that meet the modal test requirements on the blade, a wireless sensor network is formed, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com