Control method of vertical stirring device of float glass factory

A technology of vertical stirring and control methods, applied in chemical instruments and methods, mixing methods, electrical program control, etc., can solve the problems of shortened life of agitators, ineffectiveness, slow stirring speed of vertical agitators, etc., and achieves a safety factor. High, accident avoidance, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

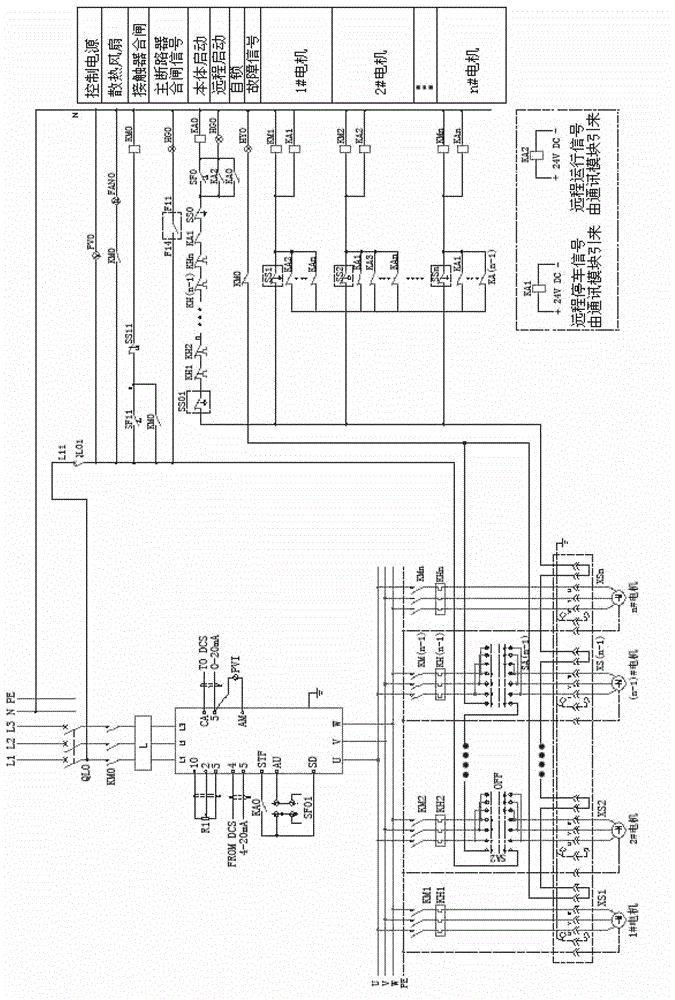

[0033] In this embodiment, a vertical agitator is included. The lower part of the agitator is equipped with 2-5 pairs of agitating impellers, and the upper part of the agitating impeller is provided with a branch drive motor, a branch high temperature resistant safety connector, a branch changeover switch, and a branch protection thermal Relays, branch contactors, start transfer switches, inverters, inverter reactors, main circuit contactors and other components.

[0034] The circuit connections of its components are as follows: figure 1 As shown, the number of control branches is determined according to the number of stirring impellers. In each control branch, the branch transmission motor, branch high-temperature safety connector, branch transfer switch, and branch protection thermal relay are in a series structure. Specific examples Say, one end of the No. 2 transmission motor is connected to the No. 2 stirring impeller, the other end of the No. 2 transmission motor is conn...

Embodiment 2

[0045] This control principle can also realize the remote start and stop of the mixer, that is, the main circuit is also equipped with a remote start switch and a remote start signal interface to realize the functions of remote control start and stop and speed adjustment.

[0046] The specific operation steps are as follows:

[0047] 1. Debugging. Set up and debug the system before baking the kiln, check the initial position of the mixing impeller of the vertical agitator and the rotation direction of the motor, so that the rotation direction of the mixing impeller and the motor is correct and meet the process requirements;

[0048] 2. Pre-preparation. After the glass is completely melted into a liquid state at the end of the roasting furnace, the control system turns to the working state, switch the start switch SF01 to the remote position, manually operate the main circuit breaker switch QL0 to close, manually operate the button SF11 to close, and the main circuit of the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap