Electric field accelerating type gas compressor

A gas compressor, accelerated technology, applied in the field of compression, can solve problems affecting the safety of the compressor, complex system control, and affecting heat transfer performance, etc., to achieve the effects of improving operating efficiency, stable output pressure, and increasing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

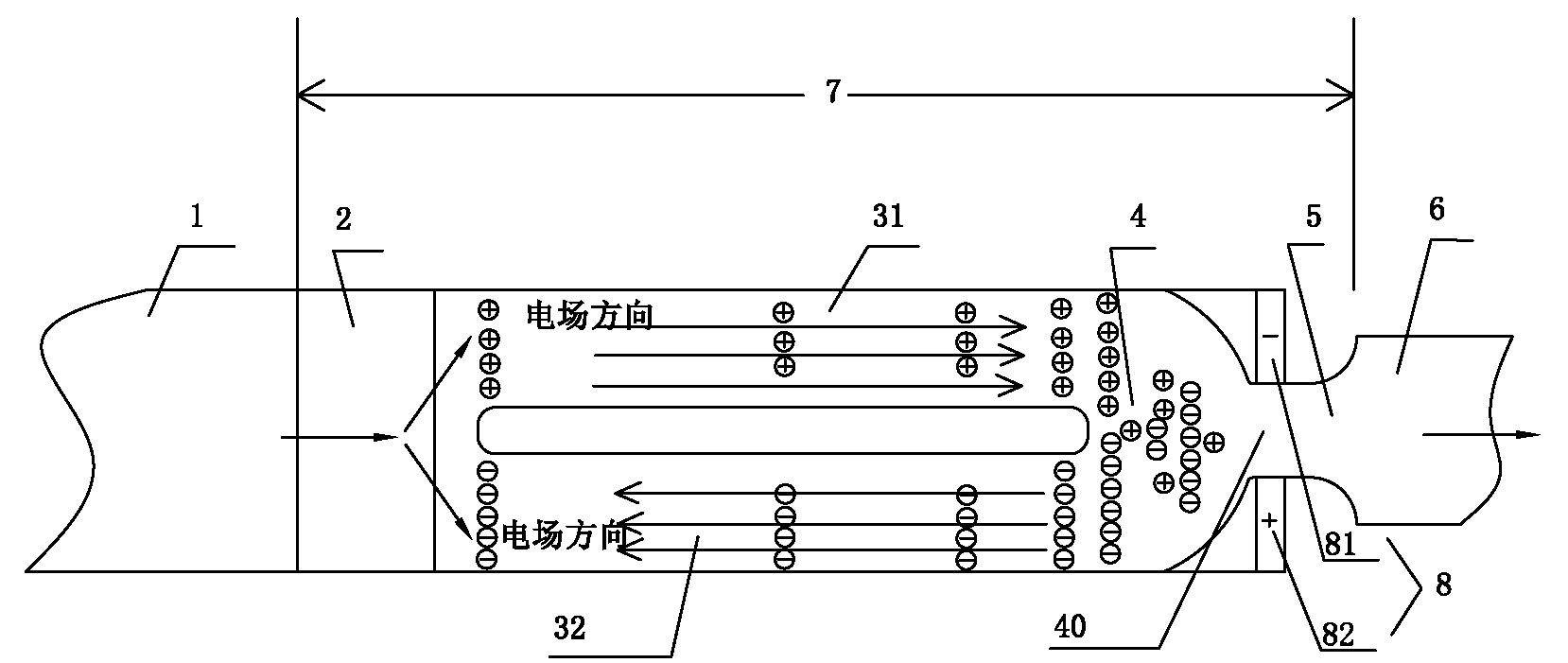

[0012] Electric field accelerated gas compressors such as figure 1 , the suction pipe 1, the compression area 7 and the exhaust pipe 6 are sequentially connected from input to output, the compression area 7 specifically: includes the ionization area 2 connected to the suction pipe 1, and the ionization area 2 is divided into two parallel branches Roads 31 , 32 , two branch roads 31 , 32 merge to form a confluence area 4 , and the confluence area 4 is output to the exhaust pipe 6 via a diffuser pipe 5 . The end section 40 of the confluence area 4 is narrowed in the middle, and an electrified body 8 is installed on the periphery of the end section 40 of the confluence area 4. The negatively charged area 81 is aligned with the first branch 31, and the positively charged area 82 is aligned with the second branch. The branch 32 forms an electric field applied to the two branches 31, 32, the electric field of the first branch 31 points to the output end, and the electric field of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap