Preparation method of negative pole material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in synthesis, and achieve the effects of easy synthesis, low temperature and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh the Co with a mass ratio of 1:3 2 o 3 8.293 grams and H 3 BO 3 9.275 grams, grind, mix evenly, add 10mL of deionized water, stir evenly, adjust flow and change phase. Transfer it into a sealed container and let it stand at 80°C for 2 hours for rheological phase treatment. Then transfer it to a ball mill jar, add 20 mL of ethanol, and ball mill at a rate of 200 rpm for 4 hours, then dry, grind, put it into a corundum crucible, and raise the temperature to 800 °C at a rate of 4 °C / min under an oxygen atmosphere. Keep it at ℃ for 6 hours, turn off the power, cool with the furnace, soak the obtained product in hot deionized water for 10 minutes, wash, filter, and dry at 80-150℃ to obtain cobalt borate material.

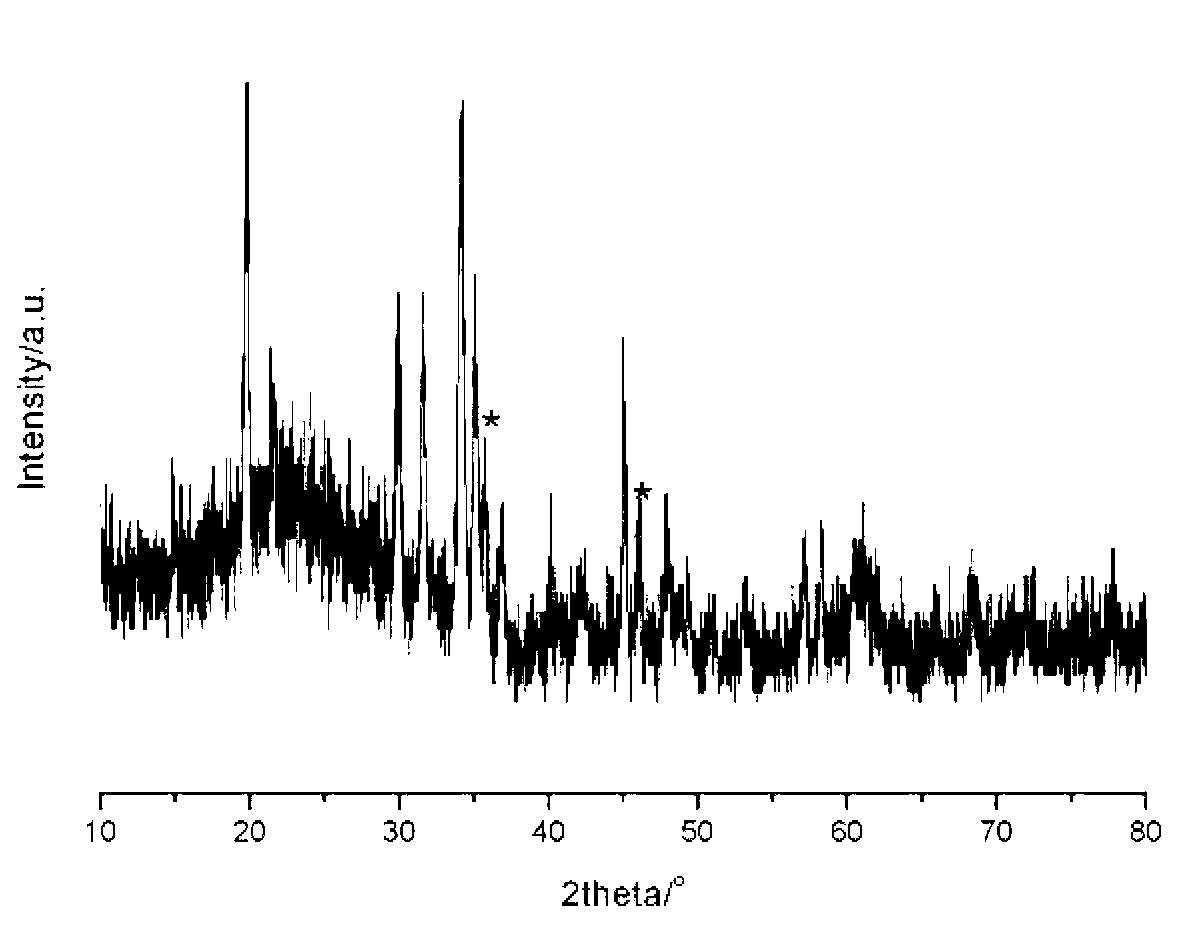

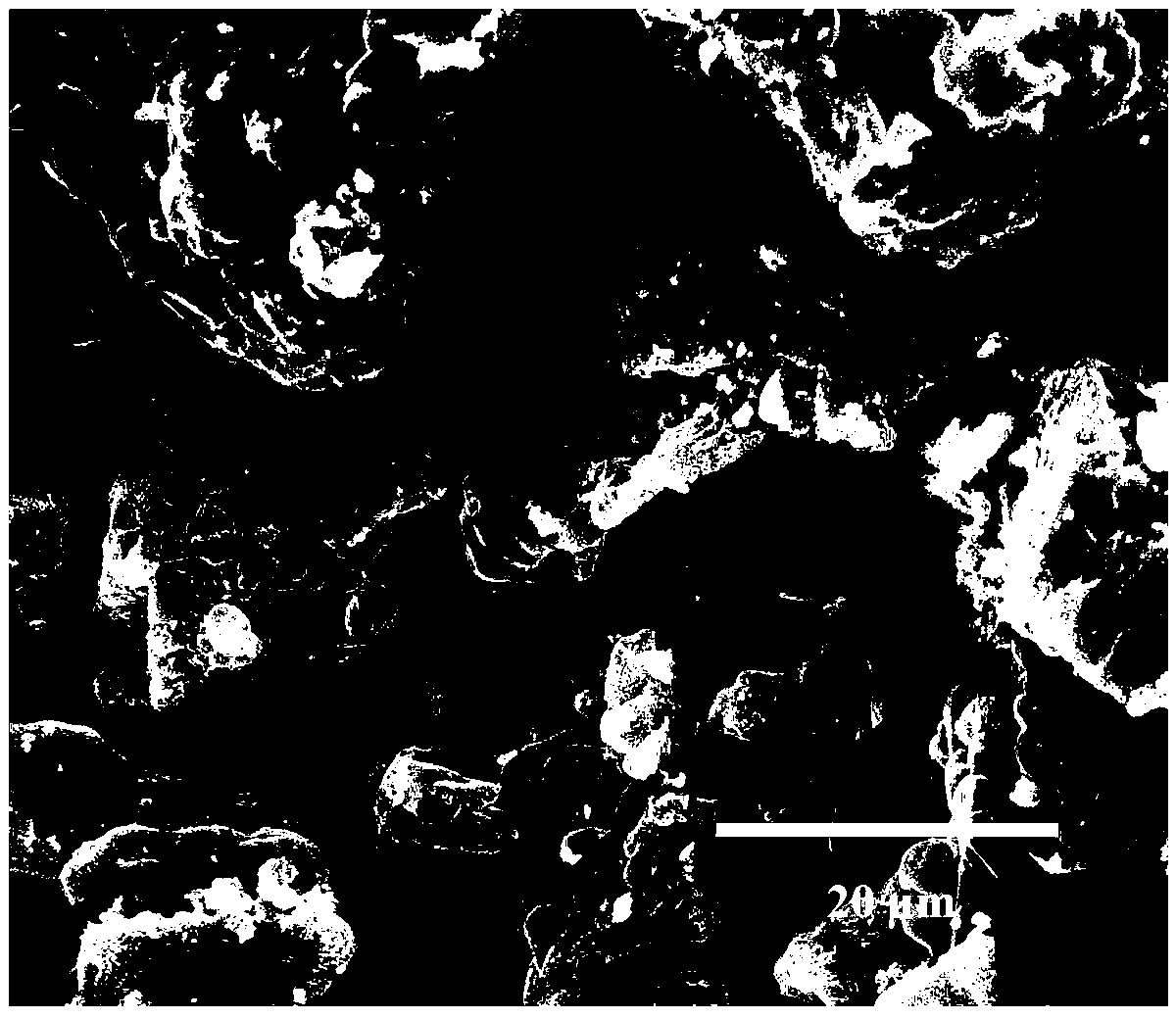

[0033] The XRD spectrum of the sample is as figure 1 , compared with the standard spectrum, except that two diffraction peaks cannot be assigned, and Mg 2 B 2 o 5 Spectra (PDF card No.16-168) are identical, indicating that the synthesized material is ...

Embodiment 2

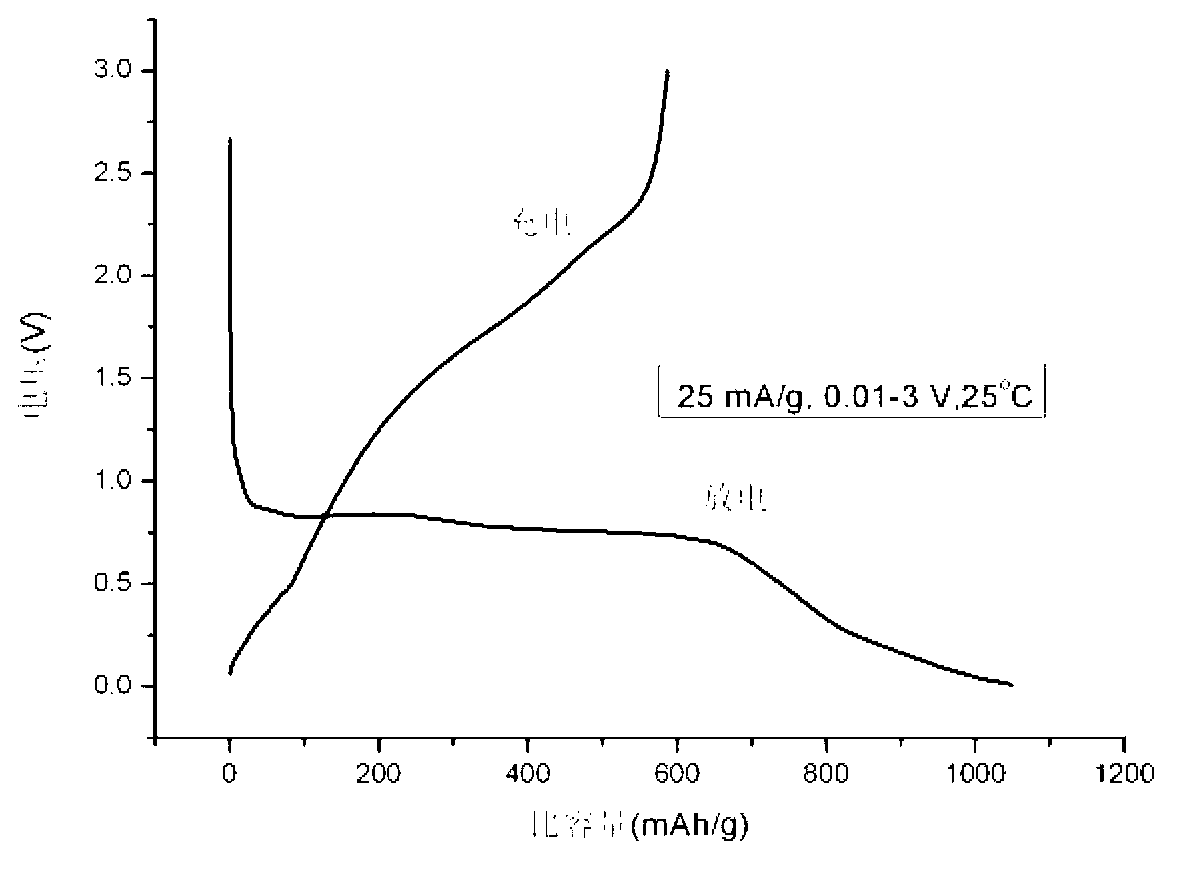

[0036] Weigh 7.493 grams of CoO and H with a mass ratio of 1:4 3 BO 312.368 grams, grind, mix evenly, add 13mL of deionized water, stir evenly, adjust flow and change phase. Transfer it into a sealed container and let it stand at 90°C for 1 hour to perform rheological phase treatment. Then transfer it to a ball mill jar, add 20 mL of isopropanol, and ball mill it at a rate of 200 rpm for 4 hours, then dry it, grind it, put it into a corundum crucible, and heat it up at a rate of 4°C / min under an oxygen atmosphere. Keep it at 850°C for 3 hours, turn off the power, cool with the furnace, soak the obtained product in hot deionized water for 1 hour, wash, filter, and dry at 80-150°C to obtain the cobalt borate material. The test conditions of the battery are the same as in Example 1, and the discharge and charge specific capacities of the first cycle are 1018mAh / g and 579mAh / g respectively.

Embodiment 3

[0038] Weigh the Co with a mass ratio of 1:1.3 2 o 3 8.293 grams and B 2 o 3 4.525 grams, grind, mix evenly, add 8mL of deionized water, stir evenly, adjust flow and change phase. Transfer it into a sealed container, and let it stand at 100° C. for 0.5 hour for rheological phase treatment. Then transfer it to a ball mill jar, add 15 mL of acetone, and ball mill at a rate of 180 rpm for 5 hours, then dry, grind, put it into a corundum crucible, and raise the temperature to 850 °C at a rate of 4 °C / min in an oxygen atmosphere. Keep at ℃ for 3 hours, turn off the power, cool with the furnace, soak the obtained product in hot deionized water for 2 hours, wash, filter, and dry at 80-150℃ to obtain the cobalt borate material. The test conditions of the battery are the same as in Example 1, and the discharge and charge specific capacities of the first cycle are 1029mAh / g and 562mAh / g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com