Method of improving buried resistance printed wire board resistance precision

A technology for printed circuit boards and embedded resistors, which is applied in the direction of containing printed electrical components and removing conductive materials by chemical/electrolytic methods, can solve problems such as poor accuracy, poor stability, and inability to make small-sized resistors, and achieves improved performance. Resistance value accuracy, reduce processing difficulty, and achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

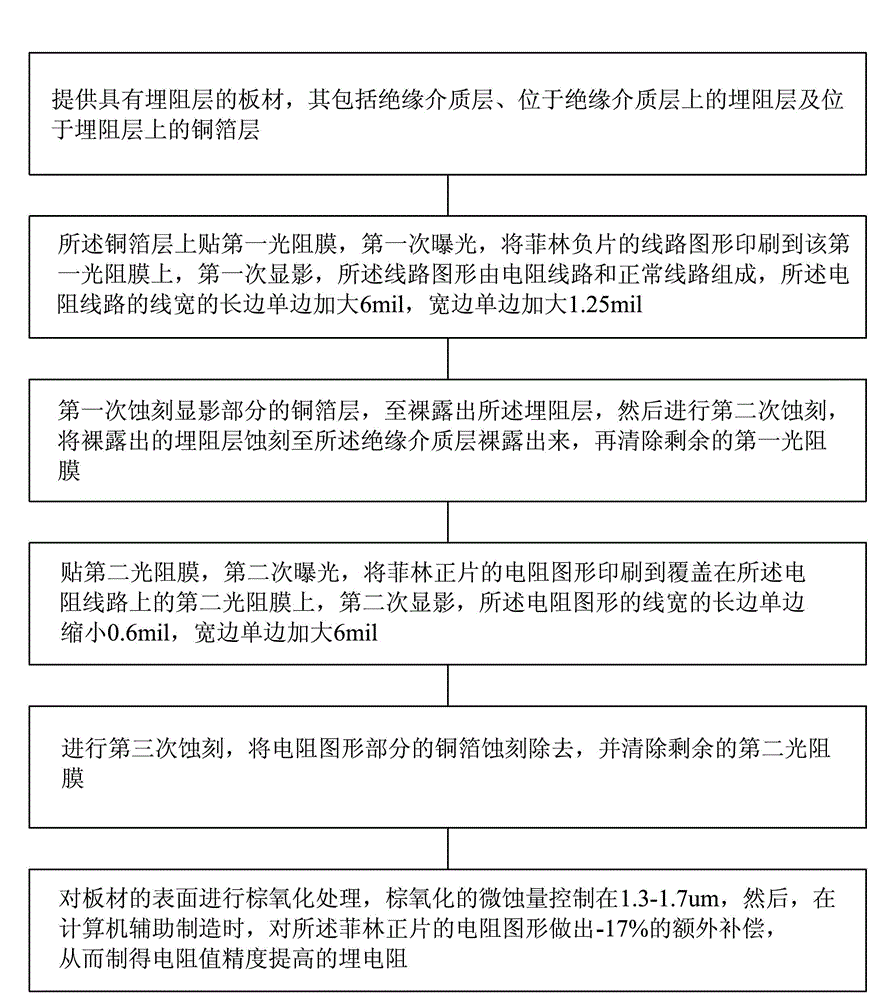

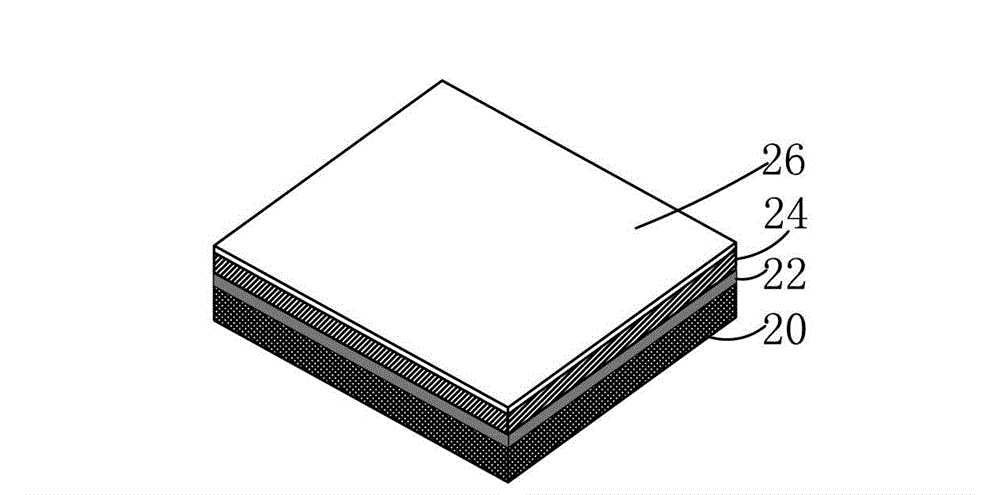

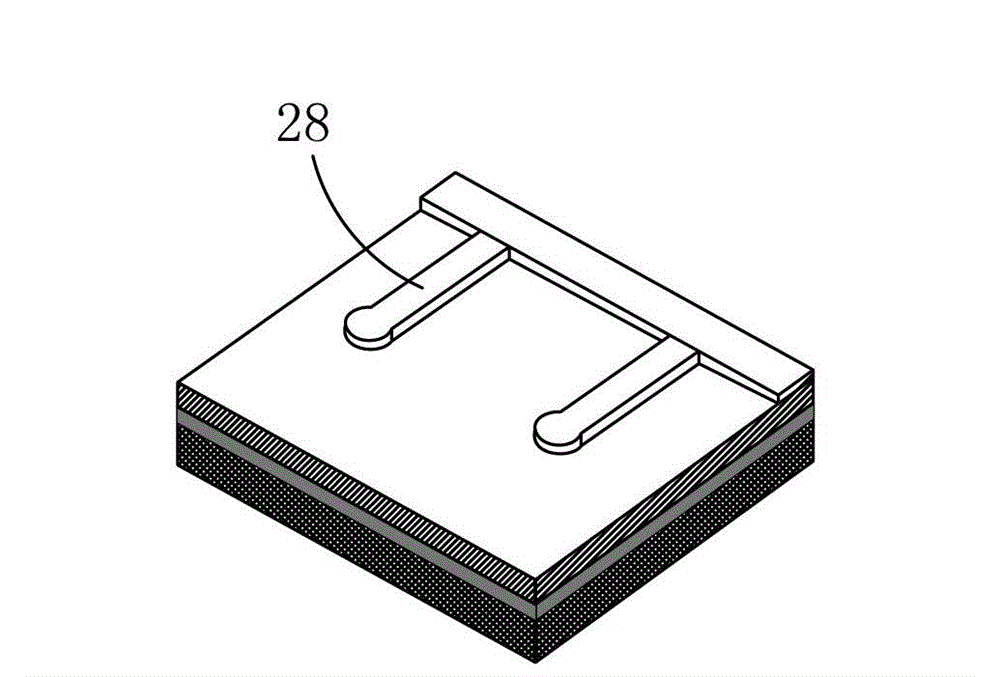

[0032] see Figure 1 to Figure 4 , the present invention provides a kind of method that improves the resistance value precision of buried resistor printed circuit board, and its technological process is as follows:

[0033] The first development → water washing → the first etching (copper etching, acid etching DES) → water washing → the second etching (ohmega-ply material etching, acid etching) → water washing → film removal → the second development → water washing → the second Three times of etching (copper etching, alkali etching SES) → water washing → second film removal.

[0034] The technical process of the buried resistance printed circuit board of the present invention is as follows:

[0035] Cutting→attaching the first photoresist fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com